Sheet metal fabrication is a crucial process in manufacturing, construction, and the automotive industries. It involves cutting, bending, joining, and finishing metal sheets to create a variety of products. Having the right tools and equipment ensures precision, efficiency, and safety in fabrication processes. In this blog, we will cover the essential tools, advanced machinery, and practical tips to ensure your fabrication projects are efficient, precise, and safe.

Essential Sheet Metal Cutting Tools

Cutting is the foundational process in sheet metal fabrication, and selecting the right cutting tool is crucial for achieving accurate, clean cuts. Here’s a breakdown of the most common cutting tools:

Shears (Manual and Powered)

Shears are versatile cutting tools used for straight or slightly curved cuts in sheet metal. Manual shears, like bench and guillotine shears, are suitable for thinner gauges and smaller projects. Powered shears, including hydraulic and electric models, offer increased cutting capacity and speed for larger sheets and thicker materials.

- Guillotine Shears: Ideal for straight, high-volume cutting. Capacity varies depending on the model, typically handling mild steel up to 10 gauge or more.

- Bench Shears: Compact and portable, suitable for lighter-gauge sheet metal and smaller workshops.

- Nibblers: Used for making intricate cuts and irregular shapes, often employed in HVAC and ductwork fabrication.

| Shear Type | Advantages | Disadvantages | Material Thickness (Mild Steel) |

| Guillotine | High-speed, accurate straight cuts | Large footprint, limited to straight cuts | Up to 10 gauge or more |

| Bench | Portable, affordable | Lower capacity, manual operation | Up to 18 gauge or more |

| Nibbler | Versatile, cuts complex shapes | Slower cutting speed, leaves a rougher edge | Up to 14 gauge or more |

Safety Precautions: You must always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, when operating shears. Keep hands clear of the cutting blades and follow the manufacturer’s safety guidelines.

Laser Cutting Machines

Laser cutting harnesses the power of a focused laser beam to melt or vaporize metal, creating precise and intricate cuts. CO2 lasers are commonly used for cutting non-metallic materials and thin-gauge metals, while fiber lasers excel at cutting thicker metals and reflective materials like stainless steel and aluminum.

- Advantages: High precision, fast cutting speeds, minimal heat-affected zone, and the ability to cut complex shapes.

- Disadvantages: Higher initial investment cost, limited material thickness capacity compared to plasma cutting.

Plasma Cutting Machines

Plasma cutting utilizes a high-velocity jet of ionized gas (plasma) to melt and sever metal. It’s particularly effective for cutting thicker materials and offers faster cutting speeds than laser cutting for these applications.

- Advantages: Cuts thicker materials than laser cutting, relatively fast cutting speed, and is cost-effective for thicker gauges.

- Disadvantages: Wider kerf (cut width) than laser cutting, can produce a rougher edge, requires more post-processing in some cases.

Water Jet Cutting

Water jet cutting employs a high-pressure stream of water mixed with abrasive particles to erode and cut through metal. Its versatility allows it to cut a wide range of materials, including metals, plastics, and composites.

- Advantages: Can cut virtually any material, no heat-affected zone, minimal material waste.

- Disadvantages: Slower cutting speed compared to laser and plasma, higher operating costs due to abrasive usage.

Sheet Metal Bending and Forming Equipment

Bending and forming are crucial processes for shaping sheet metal into desired forms. Here’s a look at key bending and forming equipment:

Press brakes

Press brakes are powerful machines used to bend sheet metal into various angles and shapes. They utilize a punch and die system to apply force and create precise bends. Different types of press brakes exist, including mechanical, hydraulic, and pneumatic.

- Mechanical Press Brakes: Utilize a flywheel and clutch system, offering high speed and precision.

- Hydraulic Press Brakes: Employ hydraulic pressure, providing greater force and control for bending thicker materials.

- Pneumatic Press Brakes: Use compressed air, making them suitable for lighter-gauge materials and smaller bending applications.

Folding Machines

Folding machines specialize in bending sheet metal along straight lines to create folds and hems. They are commonly used for box and pan bending applications.

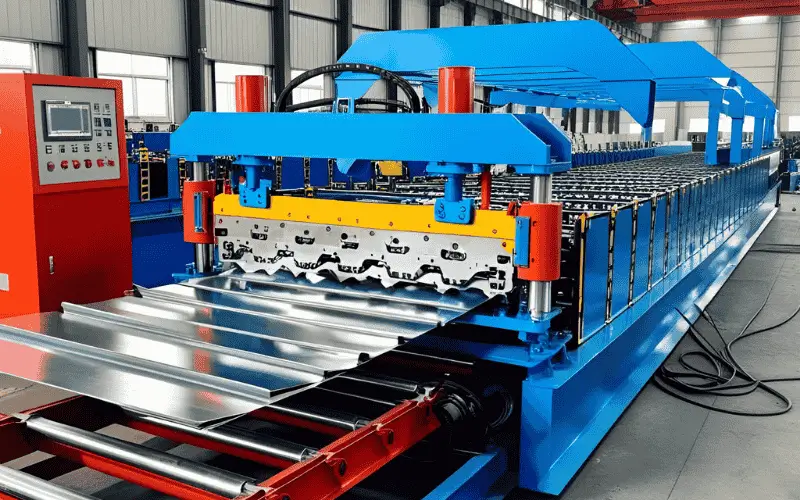

Roll Forming Machines

Roll forming machines progressively shape sheet metal into continuous profiles by passing it through a series of rollers. This process is highly efficient for producing long, uniform shapes like roofing panels and structural components.

Bead Rollers

Bead rollers create beads or ridges in sheet metal to add strength and rigidity, preventing warping and buckling. They are also used for decorative purposes.

Other Important Sheet Metal Fabrication Equipment

Beyond cutting, bending, and forming, several other tools and equipment play critical roles in sheet metal fabrication:

Welding Equipment (MIG, TIG, Spot Welding)

Welding permanently joins sheet metal pieces. MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are commonly used for sheet metal fabrication, offering different levels of precision and control. Spot welding joins overlapping sheets at specific points.

Finishing Equipment (Grinders, Sanders, Polishers)

Finishing equipment smooths and polishes sheet metal surfaces, removing burrs, sharp edges, and imperfections. Grinders, sanders, and polishers are essential for achieving a professional finish.

Safety Equipment (PPE)

Safety is paramount in sheet metal fabrication. Essential PPE includes safety glasses, gloves, hearing protection, welding helmets (when welding), and safety shoes.

Choosing the Right Sheet Metal Fabrication Tools and Equipment?

Selecting the appropriate tools depends on several factors:

- Material Type and Thickness: Different tools are designed for specific material types and thicknesses.

- Production Volume: High-volume production may require automated or specialized equipment.

- Budget: Consider the initial investment cost and ongoing maintenance expenses.

- Required Precision: The desired level of precision will influence tool selection.

- Available Space: Workshop size and layout will dictate the size and type of equipment that can be accommodated.

Maintaining Your Sheet Metal Fabrication Tools and Equipment

Regular maintenance is crucial to ensuring optimal performance and extending the lifespan of your equipment. This includes cleaning, lubrication, and periodic inspections. Be sure to consult the manufacturer’s guidelines for specific maintenance recommendations.

Conclusion

Sheet metal fabrication is a skill that takes accuracy, imagination, and proper tools. With a realization of the tools and machines at your disposal and a consideration of your specific project requirements, you can make informed decisions and generate expert work in your sheet metal fabrication operations. This guide provides a solid foundation for exploring the world of sheet metal fabrication. Don’t forget to practice safe working processes and practice regularly in an attempt to develop your expertise and expand your capabilities.

FAQs

The most common cutting tools in sheet metal fabrication include manual and powered shears such as guillotine shears, bench shears, and nibblers. For more advanced and precise applications, laser cutters are often used, while plasma cutters are ideal for thicker materials.

The choice between these cutting technologies depends on the material, thickness, and the desired finish. Laser cutting offers high precision and clean edges, making it ideal for detailed work on thinner metals. Plasma cutting is faster and better suited for thicker materials, although it may leave some roughness on the edges. Although water jet cutting is slower and more expensive, it works with a wider variety of materials and avoids thermal distortion altogether.

Welding tools commonly used include MIG, TIG, and spot welders, each serving different purposes depending on the precision and strength needed. For finishing, tools like grinders, sanders, and polishers are essential for smoothing edges, removing burrs, and giving the metal a clean, polished look.

To ensure safety during fabrication, workers should use personal protective equipment such as safety glasses, durable gloves, hearing protection, safety shoes, and welding helmets when necessary. Using the appropriate gear helps reduce the risk of injury from sharp edges, loud machinery, and high heat.