Sheet metal fabrication is a manufacturing process that involves shaping, cutting, and assembling thin metal sheets into usable products. From automotive parts to aerospace components, sheet metal fabrication is critical across numerous industries for producing precise, durable, and cost-effective metal products. In this guide, we will explore everything you need to know about sheet metal fabrication, from processes and materials to applications and benefits.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that transforms flat metal sheets into precise, functional components and custom structures for a wide range of industrial applications. This is accomplished using advanced fabrication techniques such as cutting, bending, forming, punching, laser cutting, CNC machining, and welding. The resulting products vary from simple brackets and electrical enclosures to more complex assemblies like HVAC systems, vehicle body parts, and custom machinery panels.

Sheet metal thickness typically ranges from 0.5mm to 6mm, and the process supports a diverse selection of materials, including aluminum, steel, stainless steel, and copper. After forming, components often undergo metal finishing processes like powder coating, anodizing, or galvanizing to enhance durability and appearance. This fabrication method is essential in prototyping, precision engineering, and mass production, making it a cornerstone of modern fabrication services across industries like automotive, aerospace, electronics, and construction.

What are the Key Processes in Sheet Metal Fabrication?

Sheet metal fabrication includes several processes to transform raw metal sheets into finished products. Here’s an in-depth look at the 5 main steps:

Cutting Techniques

Cutting is the first step in sheet metal fabrication and involves slicing metal sheets into desired shapes and sizes. Common techniques include laser cutting, waterjet cutting, and shearing

| Advantages | Limitations | Applications | |

| Laser Cutting | High precision, minimal waste | High equipment cost | Intricate designs, automotive parts |

| Waterjet Cutting | No heat damage, versatile | Slower than laser cutting | Aerospace, thick materials |

| Shearing | Fast and efficient for straight cuts | Limited to simple cuts | Basic sheet cutting |

Forming

Forming is a sheet metal fabrication process that reshapes flat metal by applying controlled force to create functional three-dimensional features without removing material. This process is widely used to improve part strength, rigidity, and usability while maintaining material continuity. Key concepts in forming include:

- Forming Force: The applied pressure must exceed the material’s yield strength to achieve permanent shape change without causing cracks or distortion.

- Punch and Die: Dedicated forming tools shape the metal into specific features such as flanges, ribs, embosses, or shallow drawn sections. Tool design directly affects accuracy and repeatability.

- Forming Radius: The internal radius of a formed feature is a critical parameter that helps prevent tearing and ensures consistent material flow.

- Material Flow: During forming, the metal redistributes rather than being cut, so proper control of thickness and strain is essential to maintain part quality.

- Dimensional Control: Formed parts require process control and tooling compensation to achieve stable dimensions and functional tolerances.

Punching/Stamping

Punching and stamping create holes or patterns in sheet metal. CNC machines are widely used, enabling complex designs at high speeds. The integration of robotic arms will enhance productivity and consistency.

- Punching: Uses a shaped punch to create holes or cutouts.

- Stamping: A more complex process that can create intricate shapes, embossing, and other features. It is often used for high-volume production.

Joining Techniques

- Welding: The most common joining method, where two or more metal parts are fused using heat. MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are common techniques that provide strong, permanent bonds.

- Riveting: A mechanical fastening method where a metal pin (rivet) is passed through aligned holes in two parts and deformed to lock them together.

- Adhesive Bonding: Modern industrial adhesives can create incredibly strong, vibration-dampening bonds between metal parts, often used when welding is not feasible.

- Hardware Insertion: This involves pressing special fasteners like PEM nuts (threaded inserts), studs, or standoffs into the sheet metal, providing attachment points for other components.

Finishing

Finishes are applied to protect the part from corrosion, improve its wear resistance, or provide a desired aesthetic.

- Powder Coating: A dry powder is electrostatically applied to the part and then cured with heat, creating a hard, durable, and colorful finish that is much tougher than conventional paint.

- Anodizing: An electrochemical process specifically for aluminum that creates a hard, corrosion-resistant oxide layer on the surface. It can be dyed in various colors.

- Plating: Coating the part with a thin layer of another metal, like zinc (for corrosion resistance on steel) or nickel (for wear resistance and appearance).

- Sandblasting: Propelling abrasive media at the surface to create a clean, uniform matte texture, often as a preparation for another finish.

Materials Used in Sheet Metal Fabrication

The choice of material impacts the cost, strength, and durability of the final product. Here are the most commonly used materials:

| Properties | Applications | Advantages | Disadvantages | |

| Aluminum | Lightweight, good corrosion resistance, excellent thermal and electrical conductivity | Aerospace components, transportation, and electronics enclosures | Lightweight, corrosion-resistant, good conductor of heat and electricity | Lower strength than steel, more expensive than carbon steel |

| Steel (Carbon) | High strength, relatively low cost, readily available | Automotive parts, appliances, construction, industrial machinery | Strong, durable, inexpensive, easily welded | Easy to corrode, heavier than aluminum |

| Stainless Steel | High corrosion resistance, good strength, aesthetically pleasing | Food processing equipment, medical devices, and architectural applications | Excellent corrosion resistance, hygienic, and durable | More expensive than carbon steel, it can be more difficult to weld |

| Copper | Excellent electrical and thermal conductivity, good corrosion resistance | Electrical wiring, plumbing, and roofing | Excellent conductor, corrosion-resistant, aesthetically pleasing | Expensive, relatively soft |

| Brass | Good corrosion resistance, aesthetically pleasing, good machinability | Decorative items, musical instruments, plumbing fittings | Corrosion-resistant, attractive appearance, easy to machine | More expensive than steel, lower strength than steel |

Advantages of Sheet Metal Fabrication

Sheet metal fabrication offers several benefits, making it a preferred manufacturing process:

- Cost-Effectiveness: Automation and precision tools reduce production time and costs, making fabrication economical.

- Versatility: Fabrication accommodates a wide range of designs, from simple to highly complex structures.

- Durability: Sheet metal products offer strength, corrosion resistance, and long-lasting performance.

- Sustainability: Recyclable materials and eco-friendly practices contribute to greener manufacturing processes.

Applications of Sheet Metal Fabrication

Sheet metal fabrication serves as the backbone of several industries. Here are the key applications:

Aerospace

Sheet metal fabrication plays a crucial role in the aerospace industry, where precision and durability are paramount. Fabricated components include fuselage panels, wing structures, engine mounts, and interior cabin elements. With the push for lighter, more fuel-efficient aircraft, advanced aluminum and titanium alloys are being increasingly used in aerospace fabrication.

Automotive

The automotive sector relies heavily on sheet metal fabrication for chassis components, body panels, and exhaust systems. Electric vehicles (EVs) are now driving demand for lightweight, high-strength materials to improve energy efficiency. Advances in laser cutting and robotic welding enhance production speed and accuracy, ensuring safety and performance.

Construction

In construction, fabricated sheet metal is used for roofing, HVAC systems, structural components, and decorative architectural elements. Sustainable building trends are pushing for eco-friendly metal finishes and recyclable materials. Prefabricated metal structures are also rising in popularity due to their cost-effectiveness and reduced construction time.

Electronics

Sheet metal fabrication is essential for producing enclosures, brackets, heat sinks, and conductive components in the electronics industry. With the increasing demand for 5G infrastructure and compact, high-performance devices, precision sheet metal parts are critical in shielding sensitive components and ensuring thermal management.

Renewable Energy

Renewable energy industries, including solar and wind power, heavily rely on sheet metal fabrication. Fabricated metal frames, brackets, and mounting systems support solar panels and wind turbines, ensuring durability and stability in harsh environmental conditions. Currently, advances in corrosion-resistant coatings and lightweight materials will enhance the longevity and efficiency of renewable energy installations.

Critical Design for Manufacturability (DFM) Principles

Designing for manufacturability (DFM) is crucial in sheet metal fabrication to ensure that parts can be produced efficiently and cost-effectively.

Uniform Wall Thickness

This is the most important principle. Your entire part is fabricated from a single sheet of metal, so its wall thickness must be consistent throughout. You cannot design a part that is 2mm thick in one area and 3mm in another.

Tolerances

Tolerance refers to the acceptable range of variation for a given dimension. While modern laser cutters can hold very tight tolerances (such as ±0.1mm), not every feature needs to be this precise. Specifying unnecessarily tight tolerances for non-critical features dramatically increases inspection time and cost. Use standard industry tolerances unless a feature is critical for assembly.

Bending Design

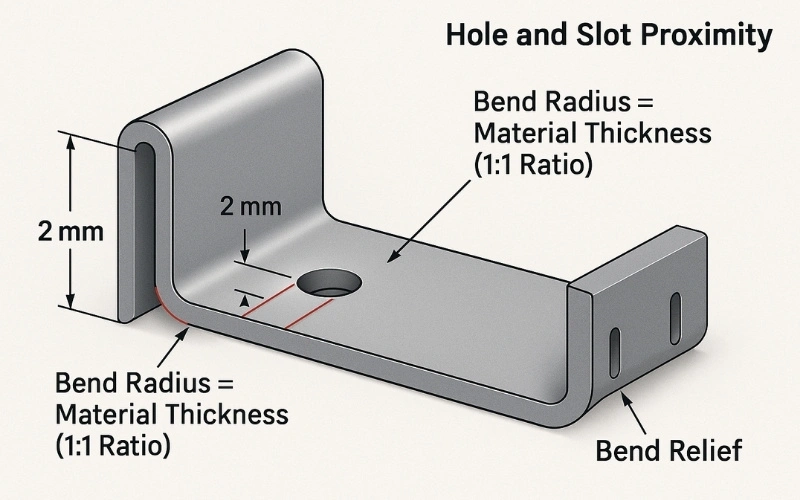

Bending is a process of controlled deformation. Pushing the material beyond its limits will cause it to fracture or distort. Follow these rules:

- Bend Radius: Always design bends with an inside radius that is at least equal to the material’s thickness (a 1:1 ratio). Tighter radii risk cracking the outer surface of the bend. For a 2 mm-thick sheet, the minimum inside bend radius should be 2mm.

- Hole and Slot Proximity: Keep all holes and slots at a distance of at least 3x the material thickness away from any bend line. When metal is bent, the material near the bend stretches and deforms. A hole placed too close will be pulled and distorted into a teardrop shape.

- Bend Relief: When a bend is made on only a portion of a flange, it can cause the material to tear at the bend’s edge. To prevent this, add small cuts called “bend reliefs” (either a slot or a round hole) at the edges of the bend. This allows the material to deform without tearing.

CAD Software and File Preparation

Leading CAD platforms include dedicated sheet metal environments with built-in design rules and unfold capabilities. SolidWorks Sheet Metal, Autodesk Inventor, and PTC Creo offer parametric modeling with automatic bend deduction calculations. These systems generate flat patterns considering material stretch and bend allowances, critical for accurate cutting. Cloud-based platforms like Onshape enable collaborative design with real-time updates, ideal for distributed teams. Specialized software like MetaCAM and SigmaNEST optimizes nesting and generates machine code directly from 3D models.

File preparation requires attention to manufacturing requirements. Export flat patterns as DXF files with clearly defined layers for cutting profiles, bend lines, and annotations. Include 3D models in STEP format for visualization and verification. Specify grain direction when relevant for bending or appearance. Remove unnecessary details like threads or small radii that complicate programming without adding value. Verify all features meet minimum size requirements for selected processes. Laser cutting can achieve smaller features than punching, but costs increase accordingly.

Innovations and Future Trends

Technological advancements and a focus on sustainability shape the sheet metal fabrication industry. Key trends include:

- Automation and AI: Automated systems and AI-driven tools optimize cutting, bending, and assembly processes, increasing efficiency and reducing errors.

- Sustainability Practices: The industry adopts green manufacturing techniques, including the use of renewable energy sources and the reduction of material waste through advanced simulation tools.

- Industry 4.0: Integration of IoT-enabled devices provides real-time monitoring and data analytics, allowing manufacturers to improve quality and efficiency.

How To Choose The Right Sheet Metal Fabricator?

Selecting the right fabricator is crucial for a successful project. Consider the following factors:

- Experience: Look for a fabricator with a proven track record in your industry.

- Certifications: Ensure the fabricator holds relevant industry certifications (such as ISO 9001).

- Equipment Capabilities: Verify they have the necessary equipment for your project’s specific requirements.

- Quality Control Processes: Inquire about their quality control measures to ensure consistent product quality.

At ABC Vietnam, we are a leading company that provides sheet metal fabrication services in Vietnam. In-house surface treatments, such as powder coating, zinc plating, nickel plating, and chrome plating, are common processes used by our manufacturers to achieve high-quality sheet metal fabrication end products. For all the processes, we also offer REACH and RoHS-compliant production solutions if required. Sheet metal fabrication and contract manufacturing are, therefore, very good production alternatives compared to countries like Eastern Europe and China.

Conclusion

Sheet metal fabrication is an indispensable process in modern manufacturing, enabling the creation of countless products across diverse industries. From the basic understanding of what it is and how it works, to the various materials, processes, design considerations, and applications, we’ve covered the key aspects of this field. The versatility and adaptability of sheet metal fabrication make it a crucial part of our everyday lives, and its continued evolution will undoubtedly keep it at the forefront of innovation. Whether you’re an engineer, a designer, or simply curious about manufacturing, understanding sheet metal fabrication is essential in today’s world.

FAQs

It depends on the application. Aluminum is lightweight and corrosion-resistant, steel is strong and affordable, and stainless steel offers excellent durability for harsh environments.

It can be cost-effective, especially for medium to large production runs. Costs vary based on material, complexity, volume, and finishing requirements.

Gauge is a unit of measurement for sheet metal thickness. Lower gauge numbers indicate thicker material. There are different gauge standards for various materials, such as steel or aluminum.

The minimum bend radius depends on the material type and thickness. A general rule of thumb is to use a bend radius at least equal to the material thickness, but it’s best to consult with a fabricator or refer to design guidelines.