Laser Cutting Service in Vietnam – Precision Metal Cutting

In modern sheet metal fabrication, laser cutting is a core manufacturing process that delivers exceptional accuracy, clean edges, and high production efficiency. At ABC Vietnam Manufacturing & Sourcing, we provide professional laser cutting services for metal sheets and tubes, supporting projects from prototypes to high-volume production with international quality standards. With advanced machinery, skilled engineers, and integrated fabrication capabilities, ABC Vietnam is a reliable partner for manufacturers seeking precision, consistency, and cost-effective laser cutting solutions in Vietnam.

What Is Laser Cutting?

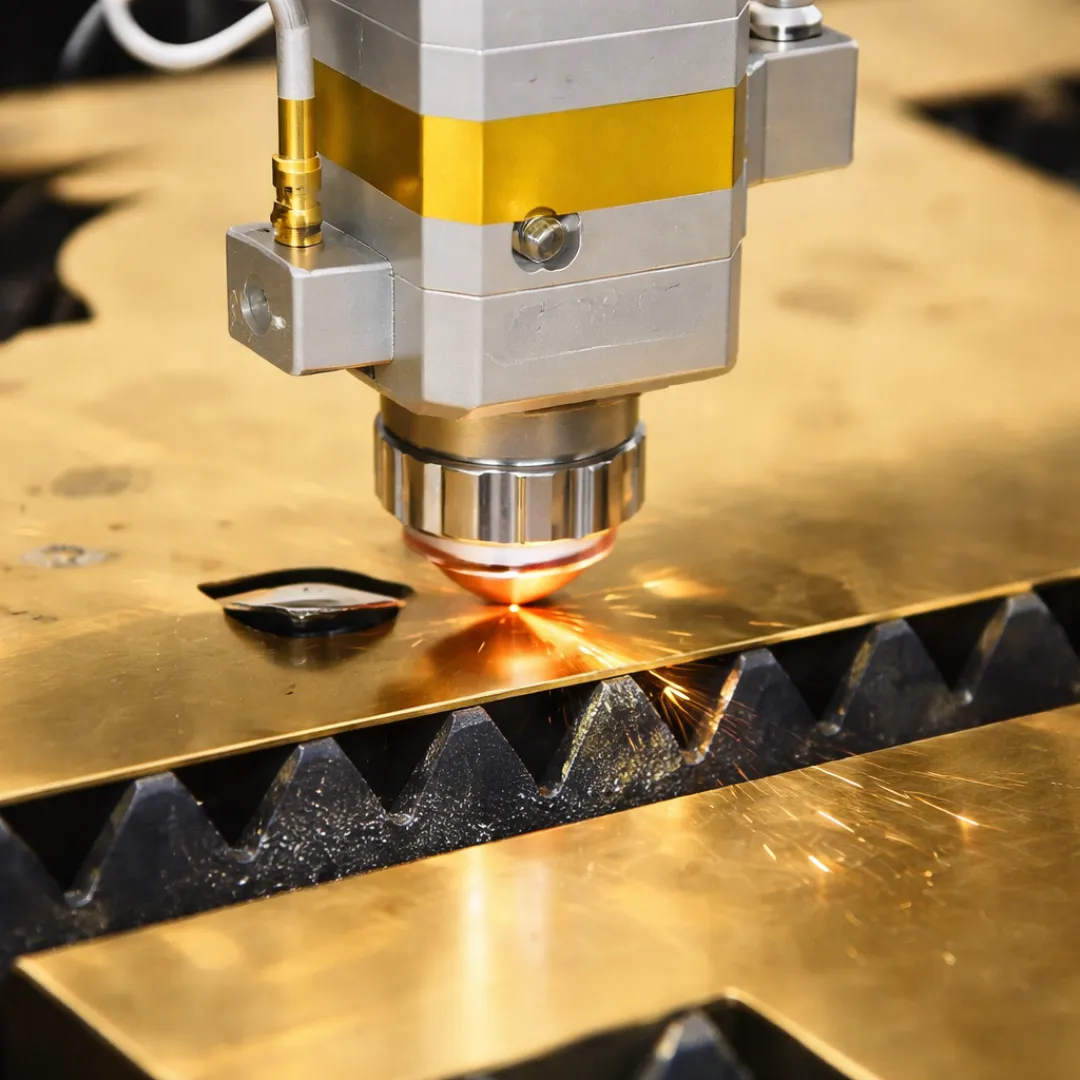

Laser cutting is a thermal cutting process that uses a high-powered laser beam controlled by CNC systems to cut metal materials according to digital design files. The laser melts or vaporizes the material along the cutting path, resulting in highly accurate cuts with minimal material distortion. Key advantages of laser cutting include:

- High-dimensional accuracy for complex and detailed geometries

- Smooth, burr-free cutting edges, reducing secondary finishing

- Fast processing speed, suitable for both small and large batches

- Excellent repeatability for mass production

- Wide material compatibility, from thin to thick metal sheets

Because of these advantages, laser cutting is widely used across industrial manufacturing, mechanical engineering, electronics, construction, and automotive sectors.

Laser Cutting Capabilities at ABC Vietnam

Our laser cutting operation is designed to meet the requirements of industrial manufacturing, rather than those of short-term or hobby-level cutting. Technical capabilities include:

- Fiber laser cutting technology for stable, high-speed cutting (using 3kw to 6 kw fiber lasers)

- Support for thin to thick metal sheets, depending on the material type

- Precise cutting for complex contours, holes, and fine features

- Consistent quality across batches for mass production

Our engineering team optimizes laser cutting parameters based on material type, thickness, and part design to ensure reliable results.

Sheet Metal Laser Cutting

We provide high-precision laser cutting for flat metal sheets used in various industrial and commercial applications. This service is suitable for:

- Panels, brackets, and enclosures

- Frames and structural components

- Custom-designed metal parts

- Prototypes and high-volume production

Our sheet metal laser cutting ensures tight tolerances, accurate hole positioning, and consistent quality throughout production.

Fiber laser round

sheet cutting

Stainless steel 10mm sheet laser cut

Fiber laser square

sheet cutting

1.2mm galvanized steel sheet laser cut

3D fiber laser

sheet cutting

0.8mm brass sheet laser cut

Tube & Profile Laser Cutting

In addition to flat sheets, we also offer laser cutting for metal tubes and profiles, supporting complex structural and mechanical designs.

Tube laser cutting capabilities include:

- Cutting round, square, and rectangular tubes

- Processing channels, angles, and metal profiles

- Accurate cutting of slots, holes, and end features

- High repeatability for frame and assembly components

This capability enables efficient fabrication of welded frames, support structures, and mechanical assemblies.

Fiber laser tube round cutting

Round tube cutting on our 3kW tube laser cutter with an automatic feeding system

Fiber laser square tube cutting

Square tubes are precisely cut on our 3kW tube laser cutter, equipped with an automatic feeder

3D fiber laser tube Cutting

3D free-form laser cutting machine, which has a 3kW fiber laser cutting source

Materials for Laser Cutting

We provide laser cutting services for commonly used industrial metals, including:

- Carbon steel: widely used for structural and mechanical parts

- Stainless steel (Inox): suitable for corrosion-resistant applications

- Aluminum and aluminum alloys: lightweight parts and enclosures

- Copper and brass: electrical and decorative components

Material selection and cutting conditions are reviewed to ensure compatibility with further forming, welding, or surface finishing processes.

Quality Control & Manufacturing Standards

Quality is managed throughout every stage of our laser cutting process to ensure consistent results and reliable part performance:

- Review of technical drawings and specifications before production, including material type, thickness, tolerances, and critical features, to confirm cutting feasibility and process suitability

- In-process dimensional and visual inspections focusing on key characteristics such as cut accuracy, hole positioning, and edge quality

- Monitoring of cutting parameters and process consistency, ensuring stable laser power, cutting speed, and repeatability across production batches

- Alignment with ISO 9001:2015 quality management standards, supporting controlled processes, traceability, and continuous improvement

Our focus is not only on cutting accuracy, but also on ensuring that laser-cut parts integrate smoothly into downstream processes and perform reliably in their final application.

Why Choose Us for Laser Cutting in Vietnam?

You may often ask yourself why you should choose ABC Vietnam for laser cutting services, right? We confidently affirm that we are the most suitable partner for you because we offer manufacturing-focused laser cutting, not just cutting capacity. What we have are:

- Experienced engineering and production teams

- Stable quality suitable for export-oriented manufacturing

- Cost-effective production through process optimization

- One-stop sheet metal fabrication capabilities

- Clear communication and technical support throughout the project

We work closely with customers to ensure laser cutting results align with their design intent and production goals. If you are looking for a reliable laser cutting service in Vietnam with industrial-grade quality and engineering support, ABC Vietnam is ready to assist.

Contact us with your drawings, material requirements, and quantity details. Our team will review your project and provide a clear technical proposal and competitive quotation.

FAQs

We typically work with standard CAD files such as DXF, DWG, or other common engineering formats. Our engineering team reviews all drawings before production to confirm technical requirements and manufacturability.

Laser cutting at ABC Vietnam delivers high-dimensional accuracy and repeatability, making it suitable for parts with tight tolerance requirements. Accuracy depends on material type, thickness, and part geometry, but laser cutting is consistently one of the most precise metal cutting methods available.

Yes. Fiber laser cutting is highly suitable for batch and mass production due to its speed, repeatability, and consistency. With CNC-controlled processes and stable laser power, ABC Vietnam can maintain tight tolerances across long production runs.