In today’s advanced manufacturing world, precision, speed, and flexibility are non-negotiable. Metal laser cutting delivers all three. Whether you’re a design engineer, metal fabricator, or manufacturer, understanding how this powerful technology works can lead to better project decisions and improved outcomes. This comprehensive guide dives deep into the principles, processes, machine types, and materials involved in metal laser cutting, helping you unlock its full potential for your applications.

What is Metal Laser Cutting?

Metal laser cutting is a high-precision, cost-effective, and technologically advanced method for cutting and engraving metal components using a focused laser beam. It applies thermal energy to melt or vaporize materials at exact points, allowing for clean edges, fine details, and minimal material waste. With technologies such as fiber laser and CO2 laser, this process ensures high-speed, repeatable, and low-tolerance cuts, ideal for industries like aerospace, automotive, electronics, and metal fabrication. Its ability to reduce the heat-affected zone and cut without contact makes it the gold standard in precision metalworking.

Read more: What is laser cutting? A comprehensive guide

How Does Metal Laser Cutting Work?

Metal laser cutting is a process that utilizes focused light energy to precisely melt, burn, or vaporize metal along defined paths. Let’s explore each critical stage of the process in detail:

Beam Generation

The laser beam originates from a laser resonator. Depending on the type (CO2, fiber, or crystal), different mechanisms generate the laser. For instance, in a CO2 laser, a mixture of gases is electrically stimulated to emit infrared light. In fiber lasers, diodes pump light through a fiber optic cable doped with rare-earth elements such as ytterbium. The quality, coherence, and intensity of this beam determine the effectiveness of the cut.

Beam Delivery

Once generated, the laser beam must be transported to the cutting head. This is done using mirrors (in CO2 lasers) or flexible fiber optic cables (in fiber lasers). Precision in beam alignment is crucial to prevent power loss or beam distortion, which can impact cut quality. The beam is then directed through a focusing lens housed in the cutting head.

Focusing

The focusing lens concentrates the wide laser beam into a tiny focal point, usually between 0.1–0.3 mm in diameter. This dramatically increases the energy density, reaching intensities of over 1 million watts per square centimeter. The focal point is positioned just below the metal surface to ensure optimal melting or vaporization. Auto-focusing systems are often used in modern machines to dynamically adjust focus based on material thickness.

Material Interaction

When the concentrated beam hits the surface of the metal, it heats the area to extreme temperatures that are enough to melt, burn, or vaporize the material. The cutting speed, laser power, and material properties all influence how the laser interacts with the metal. High-quality cuts require carefully controlled parameters to avoid burrs, dross, or uneven edges.

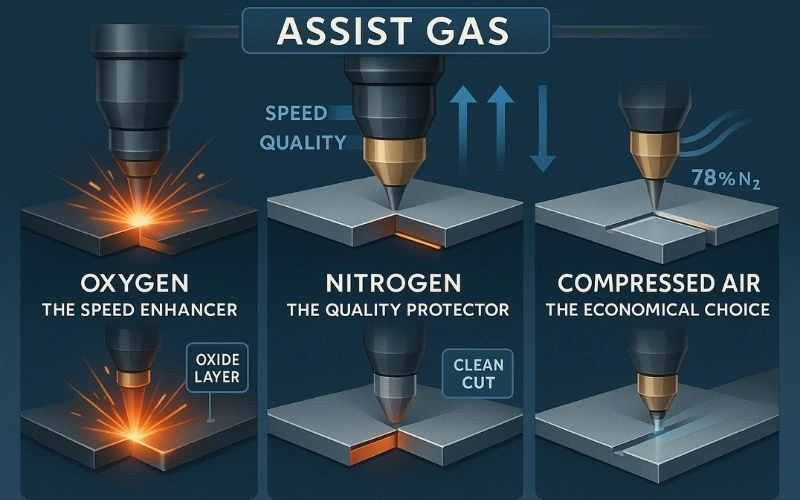

Assist Gas

The laser beam alone isn’t enough to do the job; it only provides the heat. The assist gas is the unsung hero of the process, performing two critical functions: ejecting the molten metal from the cut path (kerf) and, in some cases, aiding the cutting reaction itself. The choice of gas directly impacts cutting speed, edge quality, and cost.

Oxygen – The Speed Enhancer

When cutting carbon steel (mild steel), oxygen is the gas of choice. It creates an exothermic (heat-generating) reaction with the hot steel, which effectively adds thermal energy to the process. This allows for significantly faster cutting speeds. The trade-off is that it creates a thin layer of oxide on the cut edge, which may need to be removed before welding or painting.

Nitrogen – The Quality Protector

When cutting stainless steel, aluminum, and other non-ferrous metals, quality is paramount. Nitrogen is an inert gas, meaning it does not react with the molten metal. It is used at very high pressure to simply blow the molten material out of the kerf, preventing oxidation and leaving a pristine, shiny, burr-free edge that is ready for welding or use immediately. This is often called a “clean cut” or “nitrogen cut.” It is slower and more expensive than using oxygen, but the quality is unmatched.

Compressed Air – The Economical Choice

For cutting thin-gauge materials where edge quality is less critical, filtered, high-pressure compressed air can be used. Because air is approximately 78% nitrogen, it performs a similar function at a significantly lower cost. It can produce an acceptable edge on thin steel and aluminum, making it a great economical option for certain jobs.

CNC Control

All movements of the laser head and worktable are controlled via a Computer Numerical Control (CNC) system. The operator uploads a CAD or vector file (typically in DXF or DWG format), and the CNC system translates this into toolpaths for the laser. The system controls speed, path, beam modulation, and even pierce time, enabling automated, repeatable, precision cuts across batches.

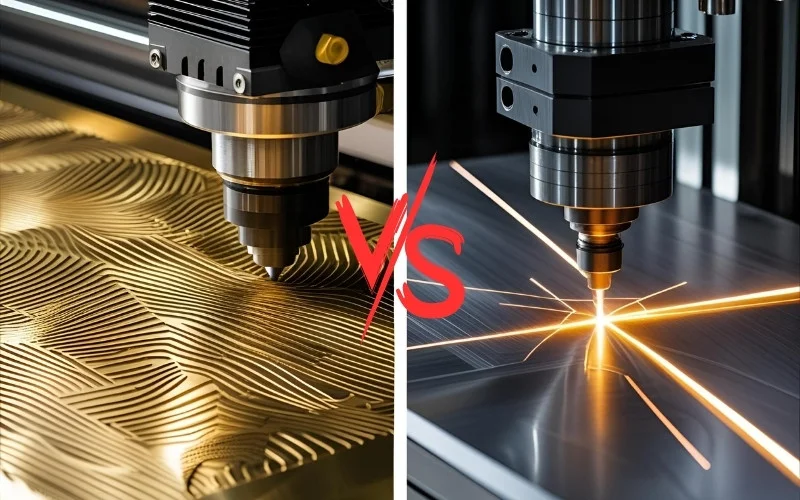

Types of Lasers for Metal Cutting

When people talk about laser cutters, they are generally referring to one of two dominant technologies: Fiber laser cutting and CO2 laser cutting. Understanding their differences is key to understanding the industry, as each has distinct advantages and is suited for different applications.

| Fiber laser | CO2 laser | |

| Wavelength | ~1.06 µm (micrometers) | ~10.6 µm (micrometers) |

| Material compatibility | Excellent for all metals, especially reflective ones like brass, copper, and aluminum. Also extremely fast on thin-gauge steel | Excellent for carbon steel, stainless steel, and thick-section cutting. Also capable of cutting non-metals like wood, acrylic, and leather |

| Electrical efficiency | Very high (~30-40%). Consumes significantly less power to generate the same cutting power | Low (~5-10%). Requires more power and a chiller system to manage waste heat |

| Maintenance | Minimal. No mirrors to align, no laser gas to replace. The “solid-state” design is very robust | High. Requires regular mirror alignment, cleaning, and replacement of laser gas mixture |

| Cutting speed | Up to 3-4 times faster than CO2 on thin-gauge metals (< 5mm). Slower on very thick steel (> 20mm) | Slower on thin materials but produces a superior, smoother edge quality on thick-plate steel (> 20mm) |

| Initial investment | Historically higher, but prices have become very competitive and are often lower now for comparable power levels | Generally, lower initial capital cost for high-power systems, but higher operating costs over time |

For the vast majority of modern metal cutting applications, especially involving thin-to-medium thickness steel and reflective metals, fiber lasers are the superior choice due to their speed, efficiency, and low maintenance. CO₂ lasers still hold a niche for cutting very thick plate steel and for shops that need the versatility to cut organic materials

What Metals Can Be Laser Cut?

The success of your project also depends on choosing the right material and understanding the technology’s capabilities with that material. While lasers are incredibly versatile, performance varies. Metals such as carbon steel, stainless steel, aluminum, brass, copper, and titanium are among the most commonly used. The table below provides detailed information about each metal.

| Best laser type | Maximum recommended thickness | Cut quality and notes | |

| Carbon steel | Fiber or CO₂ | 25 mm (1 inch) | Excellent results with oxygen-assist gas for speed. Smooth edge, but with a thin oxide layer. It is good for structural and general fabrication |

| Stainless steel | Fiber (highly preferred) | 20 mm (0.75 inch) | Requires Nitrogen assist gas for a clean, oxide-free, bright edge. The finish is beautiful and ready for welding |

| Aluminum | Fiber | 20 mm (0.75 inch) | Highly reflective. Fiber lasers are essential for reliable cutting. Requires high-pressure Nitrogen for a clean, burr-free edge |

| Brass | Fiber | 10 mm (0.4 inch) | Very reflective. A modern fiber laser is required. Cuts cleanly with Nitrogen, producing excellent results for decorative and electrical parts |

| Copper | Fiber | 8 mm (0.3 inch) | The most reflective common metal. Extremely difficult for CO₂ lasers. Fiber lasers handle it well with Nitrogen gas |

| Titanium | Fiber | 12 mm (0.5 inch) | Cuts very well with nitrogen, leaving a high-quality, non-contaminated edge suitable for aerospace and medical applications |

What are The Advantages of Metal Laser Cutting?

Here are some benefits of metal laser cutting:

- High precision and speed: Achieves tolerances of ±0.1mm and speeds up to 50m/min, which is 50% faster than plasma in many cases

- Excellent cut quality: Edges are clean, smooth, and square, often eliminating the need for costly secondary deburring or finishing operations.

- Automation: CNC control allows for “lights out” manufacturing, producing thousands of identical parts with perfect repeatability and minimal labor.

- Material versatility: A single machine can cut a vast range of metals of varying thicknesses.

- Low part distortion: The heat-affected zone (HAZ) is very small, and the non-contact nature means there’s no mechanical stress, so thin materials stay flat.

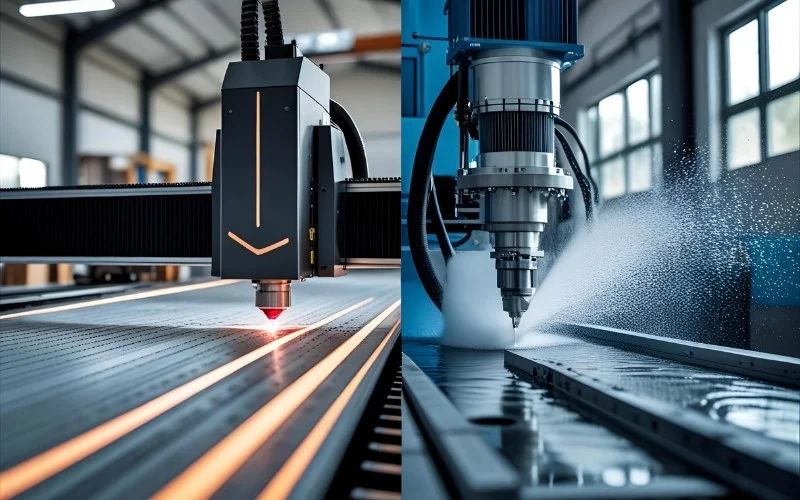

Metal Laser Cutting vs Other Cutting Methods

When it comes to choosing a cutting method for metal fabrication, it’s important to weigh the benefits and drawbacks of laser cutting compared to other popular technologies. Below is a comparison to help you understand where laser cutting excels and where alternative methods may be more appropriate.

| Precision | Speed | Cost | Best for | |

| Laser | High (±0.1mm) | High (50m/min) | Medium-high | Complex shapes, thin metals |

| Plasma | Medium | High | Low | Thick plates, rough cuts |

| Waterjet | High | Medium | Medium | Heat-sensitive materials |

| CNC punching | Medium | High | Low | Repetitive holes |

Tips and Best Practices for Optimal Metal Laser Cutting

Here are some tips that we’ve refined over the years of troubleshooting from our ABC Vietnam experts that can elevate your results.

- Design smart: Avoid sharp corners (use fillets) to prevent heat buildup.

- Choose parameters: Match power to thickness, such as 3kW for 5mm steel.

- Maintain equipment: Clean lenses weekly to avoid beam scatter.

- Troubleshoot errors: For burrs, increase gas pressure; for warping, slow speed.

Checklist:

- Test on scrap material first.

- Use protective eyewear (per safety standards).

- Optimize nesting to minimize waste.

Conclusion

Metal laser cutting offers unparalleled precision, speed, and versatility across industries. Whether you’re designing complex aerospace components or customized signage, this process offers efficiency without compromising on quality. By understanding the machines, materials, and techniques involved, you can make smarter choices for your project or business. If you’re ready to explore laser cutting options or services, contact us today to discuss your needs.

FAQs

No, a 10W laser is far too weak to cut metal. It is typically used for engraving soft materials like wood, acrylic, or cardboard.

A 40W CO2 laser cannot effectively cut metal. It may be able to mark coated metals, but it is insufficient for through-cuts.

Yes. A 100W CO2 laser can cut fragile sheet metal, such as mild steel, under specific conditions, but it is not suitable for consistent industrial metal cutting.