Traditional tube cutting often leads to misalignment, excessive rework, and design limitations that slow production and increase costs. These issues become even more painful as product complexity and quality expectations rise. Laser tube cutting solves this by delivering precise, repeatable cuts and design flexibility in a single automated process. This article breaks down how laser tube cutting works, where it adds the most value, and how to use it effectively in modern fabrication workflows.

What Is Laser Tube Cutting?

Laser tube cutting is an advanced CNC-controlled metal fabrication process that uses a high-powered fiber laser beam to cut, slot, drill, and contour hollow metal profiles such as round, square, and rectangular tubes and pipes. Unlike flat sheet laser cutting, this 3D laser cutting technology rotates and feeds the material automatically while the laser follows a programmed cutting path, enabling high precision, tight tolerances, complex geometries, and minimal secondary processing on materials like stainless steel, carbon steel, and aluminum for structural and manufacturing applications.

Read more: What is Laser Cutting? A Comprehensive Guide

How Does Laser Tube Cutting Work?

At a high level, laser tube cutting involves a laser resonator (either Fiber or CO2) generating a beam that melts and vaporizes material, assisted by a high-pressure gas (nitrogen or oxygen) to blow away the molten metal. But the magic lies in the material handling.

The Chuck System and Dynamics

Unlike flatbed lasers, where the sheet is stationary, a tube laser is highly dynamic.

- The Rear Chuck: Grips the raw tube stock and feeds it forward into the cutting zone.

- The Front Chuck: Stabilizes the tube near the cutting head to prevent vibration.

- The Steady Rest: Supporting rollers that prevent long tubes from sagging or “whipping” as they rotate rapidly.

The “Whip” Effect: A critical factor often overlooked is the rotational speed. If you are cutting a square tube with heavy walls, rotating it at high RPM creates immense centrifugal force. If the machine cannot stabilize the tube, the cut quality degrades. High-end machines utilize “active dampening” to counteract this, ensuring accuracy even on 20-foot lengths

Fiber Laser vs CO2 Laser for Tubing

While CO2 lasers were the industry standard for decades, Fiber lasers have largely taken over.

- Fiber Lasers (1.06 µm wavelength): The beam is delivered via a fiber optic cable. It is absorbed roughly 3x better by metal than CO2. It is faster on thin materials and, crucially, can cut reflective metals like copper and brass without damaging the machine optics.

- CO2 Lasers (10.6 µm wavelength): These use mirrors to deliver the beam. While slower and more maintenance-heavy, they historically offered slightly smoother edge quality on thick mild steel (over 0.5″). However, modern high-power fiber lasers (10kW+) have largely closed this gap.

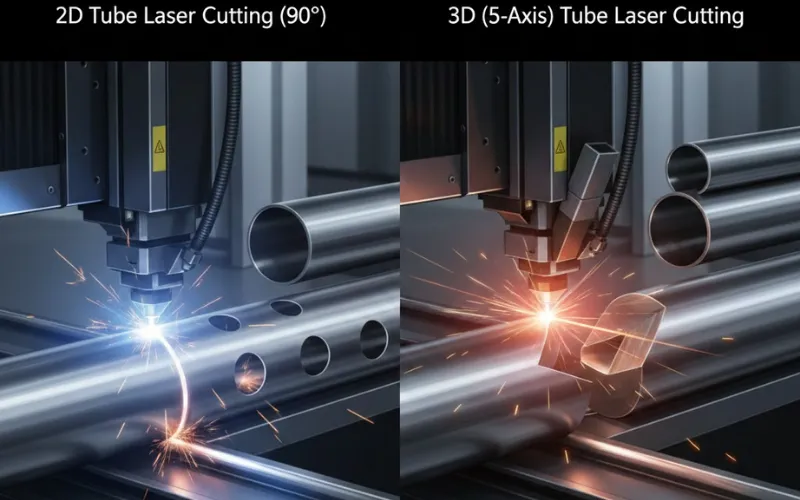

2D vs 3D (5-Axis) Cutting

Most entry-level questions regarding tube cutting assume a 2D process: the laser head cuts perpendicular (90 degrees) to the tube surface. This is sufficient for holes and cut-offs. However, advanced 5-axis (3D) tube lasers can tilt the cutting head up to 45 degrees. This capability adds a layer of value that solves a major downstream problem:

- Weld Preparation: A 3D head can cut a bevel directly onto the tube end. Instead of a welder having to grind a V-groove into a thick-walled pipe manually, the laser does it during the cut cycle.

- Intersection Accuracy: When a round tube meets another round tube at an angle (a “saddle” cut), a 3D head ensures the edges are chamfered for a perfect flush fit, significantly increasing the strength of the final weld.

Advantages Over Traditional Fabrication

Not all stainless steels behave the same under laser welding conditions. Chemical composition and microstructure play a critical role in weldability.

If you are justifying the cost of laser cutting to a client or manager, the argument is rarely about the “cost per cut” (which might be higher than a bandsaw) but the “cost per finished part.

| Traditional Fabrication (Saw + Drill + Mill) | Laser Tube Cutting | |

| Process flow | Discontinuous. Requires moving parts between multiple stations (Saw | Continuous. Raw stock in, finished part out. One setup. |

| Tolerances | Cumulative Error. Every time you move the part to a new fixture, you lose accuracy. Typical: ± 0.030″ | Single Reference. All features are cut relative to the same datum. Typical: ± 0.005″ − 0.010″ |

| Tooling costs | High. Requires drill jigs, saw fixtures, and milling clamps. | Zero. Changes are made in software. No hard tooling required. |

| Design geometry | Limited. Restricted to circular holes (drills) and straight cuts (saws). | Unlimited. Can cut slots, complex patterns, etching, and organic shapes. |

Critical Technical Challenges in Laser Tube Cutting

While laser tube cutting offers precision, flexibility, and automation advantages over traditional methods, the process also presents several technical challenges that can compromise part quality, productivity, and operational safety if not properly managed. Understanding these challenges, from material behaviors to machine limitations, is essential for engineers, fabricators, and manufacturing decision-makers who want consistent, high-quality results.

Weld Seam Detection

Almost all structural tubing (HSS) is formed by rolling and welding strip steel, which creates a continuous weld seam along the tube length.

- Problem: The weld seam is typically harder and thicker than the surrounding material and often has different metallurgical properties. When precision features such as holes or slots are cut directly through the seam without compensation, the laser may fail to penetrate cleanly, resulting in poor edge quality, excessive burrs, or incomplete cuts. For visible or architectural parts, the weld seam can also create unwanted cosmetic defects.

- Solution: Modern tube laser systems use optical cameras or seam-detection sensors to identify the weld seam location before cutting. The machine automatically rotates the tube so the seam is positioned away from critical features or hidden on a non-visible face, ensuring consistent cut quality and improved aesthetics.

Cutting Reflective Materials

Materials such as aluminum, copper, and brass are increasingly used in lightweight and high-performance applications, but they present unique laser cutting challenges.

- Problem: Highly reflective materials absorb less laser energy and can reflect a portion of the beam back toward the cutting head. This reduces cutting efficiency, degrades edge quality, and can potentially damage optical components if not properly controlled.

- Solution: Modern fiber lasers incorporate back-reflection protection, adaptive power control, and optimized wavelengths that improve energy absorption. Using the correct assist gas (typically high-purity nitrogen) and carefully tuned cutting parameters further stabilizes the process and produces clean, consistent edges.

Thermal Distortion and Heat Accumulation

Laser tube cutting relies on concentrated heat, which can affect part geometry if not managed correctly.

- Problem: Excessive heat input (especially on thin-wall tubes or complex cut patterns) can cause warping, dimensional drift, or localized changes in material properties near the cut edge. Long continuous cuts may allow heat to build up faster than it can dissipate.

- Solution: Advanced tube laser software uses optimized cutting sequences, segmented toolpaths, and dynamic feed-rate control to manage heat distribution. In some cases, strategic pauses or alternating cut locations are programmed to allow the tube to cool, maintaining dimensional accuracy.

Burr Formation and Internal Dross

Clean edges are essential for welding, assembly, and overall part quality.

- Problem: Improper laser power, focus position, or assist gas settings can lead to burrs on the cut edge or molten material (dross) adhering to the inside of the tube. Internal dross is especially problematic because it is difficult to remove and can interfere with downstream processes.

- Solution: Achieving burr-free cuts requires precise parameter tuning, including correct focal position, nozzle alignment, and stable assist gas pressure. High-quality tube laser systems also use real-time monitoring to maintain consistent cutting conditions throughout the process.

Tube Clamping and Vibration Control

Accurate cutting depends on stable material handling throughout the entire operation.

- Problem: Long tubes, thin walls, or uneven stock can vibrate or shift during rotation and feeding. Even minor movement can cause dimensional inaccuracies, inconsistent hole positioning, or tapered cuts.

- Solution: Modern machines employ adaptive clamping systems, multiple support points, and servo-controlled rotation to stabilize the tube. These systems automatically adjust grip force based on tube size and wall thickness, maintaining precision without deforming the material.

Software and Programming Accuracy

Laser tube cutting is only as accurate as the data driving the machine.

- Problem: Incorrect CAD models, poor nesting strategies, or mismatched post-processors can result in misaligned features, collisions, or wasted material. Errors at the programming stage often propagate across entire production batches.

- Solution: Advanced tube laser software integrates 3D simulation, collision detection, and automatic nesting to validate programs before cutting begins. Experienced operators and engineers review designs for manufacturability, reducing errors and material waste.e root side).

Design Considerations for Laser Tube Cutting

Designing parts for laser tube cutting is not just about what can be cut, but what can be cut consistently, accurately, and cost-effectively in real production environments. Applying the following design considerations early in the design phase improves cut quality, reduces lead time, and minimizes downstream issues during welding and assembly.

Tolerances and Dimensional Accuracy

Laser tube cutting delivers high precision, but realistic tolerance planning is essential for manufacturability.

- Typical achievable tolerances range from ±0.1 mm to ±0.25 mm, depending on tube length, wall thickness, and material.

- Long tubes are more sensitive to straightness variation from the raw material, which can influence hole-to-hole positioning.

- Over-constraining tolerances can increase cost without improving functional performance.

Best practice: Apply tight tolerances only where functionally required (like mating features) and allow looser tolerances elsewhere to improve yield and reduce inspection effort.

Wall Thickness and Tube Diameter Ratio

Not all tube geometries behave the same under laser cutting.

- Thin-wall tubes (<1.5 mm) are more prone to vibration, collapse, and heat distortion.

- Large diameters with thin walls require careful clamping and conservative cutting parameters.

- Very thick walls may require slower speeds and higher power, affecting cycle time.

Note: Consult with the fabricator early when designing thin-wall or large-diameter tubes to validate feasibility and optimize parameters.

Tube Material & Grade Selection

Different tube materials absorb laser energy at different rates, which affects cutting speed, edge quality, and heat input. Reflective materials such as aluminum and certain stainless steels require more stable parameter control, while high-strength steels may need slower speeds to maintain clean edges.

- Cutting behavior varies significantly between mild steel, stainless steel, aluminum, and galvanized tubes

- Higher alloy or high-strength grades can increase heat-affected zones if not properly optimized

Note: Always specify the exact material grade in your design files and avoid unnecessary grade variation within the same part family. This allows manufacturers to fine-tune laser power, focus position, and assist gas for consistent results.

Weld Seam Awareness

Most structural tubes are roll-formed and welded, leaving a longitudinal weld seam with different hardness and chemistry compared to the base material. Cutting through this seam without consideration can affect accuracy and surface finish.

- Avoid placing critical holes or slots directly on the weld seam.

- For visible or architectural parts, the seam should be positioned on a hidden face.

- Seam location can shift slightly between suppliers or tube batches.

Best practice: Specify weld seam orientation when it matters, and design features so minor seam variation does not impact functionality.

Feature Accessibility & Cutting Orientation

Although tube lasers can perform complex 3D cuts, physical accessibility still matters. Certain feature placements may require repositioning or limit cutting head movement.

- Closely spaced or overlapping features can restrict cutting angles

- Deep internal cuts may reduce cutting stability

Best Practice: Allow sufficient spacing between features and avoid unnecessary complexity. Design with tube rotation and clamping in mind to ensure all features are easily accessible in a single cutting setup.

How to Choose the Right Laser Tube Cutting Service Provider?

Choosing the right laser tube cutting service provider is critical to achieving consistent quality, cost efficiency, and reliable lead times. Beyond machine specifications, the best partners combine advanced fiber laser technology, engineering know-how, and disciplined quality control to support your project from initial design through full-scale production.

- Laser tube cutting capability: Fiber laser power, multi-axis control, and supported tube shapes and sizes must match your material, thickness, and geometry requirements

- Engineering & DFM support: Ability to review CAD files, optimize tolerances, and suggest design improvements before production begins

- Material control & traceability: In-house material sourcing or qualified suppliers, consistent tube quality, and material certifications when required

- Quality management system: Documented inspection processes, calibrated measurement tools, and compliance with recognized standards such as ISO 9001

- Value-added fabrication services: Secondary processes like bending, welding, surface treatment, and assembly to reduce lead time and coordination risk

- Production scalability: Proven capacity to scale from prototypes to medium or high-volume manufacturing without sacrificing accuracy

ABC Vietnam – Your Best Provider

We stand out as a manufacturing-focused laser cutting service provider, not just a basic contract cutter. With advanced fiber laser systems capable of stable, high-speed cutting for both sheet metal and tubes, our team supports projects from single prototypes to high-volume runs with consistent precision and industrial quality standards. Our engineering experts optimize cutting parameters based on material, thickness, and part design, ensuring reliable results that integrate smoothly into welding, assembly, or finishing processes. Contact us today to discuss your requirements and receive expert guidance for your next laser cutting project.

Conclusion

Laser tube cutting is a key manufacturing technology for producing precise, complex tubular components with high consistency. Understanding its capabilities, technical challenges, and design requirements helps manufacturers improve part quality while reducing lead time and cost. Ultimately, consistent results depend on both the technology used and the expertise of the service provider. With the right partner, laser tube cutting delivers reliable performance, flexibility, and long-term production efficiency.

FAQs

Modern systems routinely achieve tolerances suitable for direct welding and assembly, often within fractions of a millimeter.

Yes. Improved fit-up and consistent geometry significantly reduce welding preparation and alignment time.

Capabilities vary by machine, but many systems handle tubes several meters long with a wide range of diameters.