Stainless steel is widely used across industries like construction, automotive, aerospace, and medical equipment due to its strength, corrosion resistance, and visual appeal. However, its toughness and reflectivity can make traditional cutting methods slow or costly. Laser cutting offers a solution by using a focused laser beam and assisting gases to produce clean, precise cuts, even in complex designs. This article covers the laser cutting process, its benefits, and practical tips, offering valuable insights for engineers, procurement managers, and students alike.

What is Laser Cutting for Stainless Steel?

Laser cutting stainless steel is a high-precision manufacturing process that uses a computer-controlled fiber or CO2 laser with assist gas to deliver clean, smooth edges, tight tolerances, and minimal waste when cutting sheet metal grades like 304 and 316. Known for its speed, energy efficiency, and reduced distortion, laser cutting outperforms plasma and waterjet cutting and is widely applied in automotive, aerospace, construction, and medical device fabrication, offering cost-effective, scalable, and sustainable production with superior edge quality and corrosion resistance.

Read more: What is Metal Laser Cutting?

How Does the Laser Cutting Process Work for Stainless Steel?

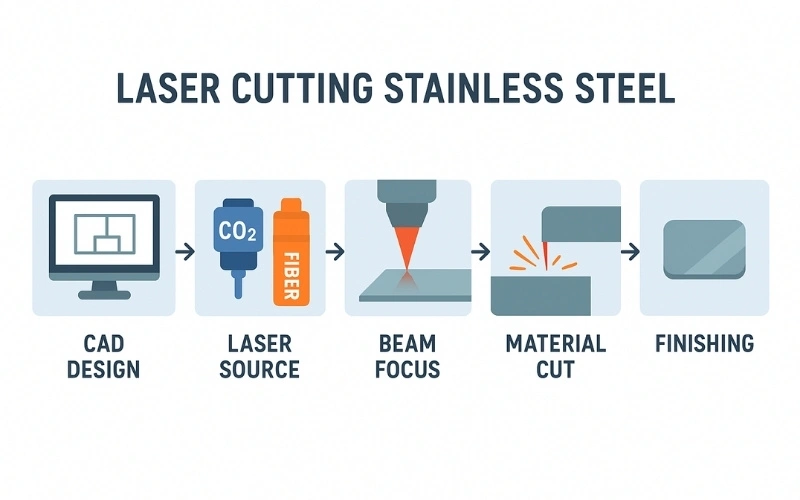

The laser cutting process for stainless steel involves a series of precise steps:

Preparing Design

The process begins with design preparation. Engineers create a CAD (Computer-Aided Design) file that contains the part’s exact geometry, dimensions, and tolerances. This digital blueprint is then converted into CAM (Computer-Aided Manufacturing) instructions, which guide the laser cutting machine. Nesting software is often used at this stage to arrange multiple parts on a sheet of stainless steel in the most efficient way possible. Good nesting reduces scrap and can cut overall material costs by a significant margin. If the CAD file is inaccurate or the nesting is poorly done, no amount of machine precision can save the final part from being defective or wasteful.

Laser Source Selection

Once the design is ready, the laser source is selected. The choice depends on the type and thickness of stainless steel being cut. CO2 lasers, once common, are less efficient for reflective metals. Fiber lasers, which dominate today’s market, offer far greater absorption, faster cutting speeds, and lower maintenance requirements, making them the preferred choice for stainless steel across industries. In specialized applications such as medical devices, where extremely fine features are needed, Nd:YAG lasers may be used for micro-cutting. Most modern industrial stainless steel cutting is done with fiber lasers in the range of 2 to 12 kilowatts, which provides an optimal balance between speed, precision, and energy efficiency.

Beam Delivery and Focusing

After choosing the source, the machine must deliver and focus the beam. In CO2 systems, mirrors guide the beam, while fiber lasers use fiber-optic cables. Either way, the energy is directed to a focusing lens that narrows the beam to a spot often no wider than 0.1 to 0.3 millimeters. This tiny focal point is crucial because it determines the kerf, or the width of the cut. A correctly adjusted focus ensures that the beam penetrates the stainless steel efficiently, producing sharp, narrow edges. An error at this stage, even by a fraction of a millimeter, can mean the difference between a smooth, continuous cut and one riddled with incomplete sections or rough edges.

Cutting Mechanism (Material Removal)

The heart of the operation is the cutting mechanism itself. When the laser beam strikes the stainless steel, it raises the temperature above the metal’s melting point, which is typically between 1400 and 1500 degrees Celsius. At the same time, a jet of assist gas clears away the molten metal from the cut zone. The choice of gas influences both speed and edge quality. Oxygen can accelerate the process through an exothermic reaction, but often leaves a dark, oxidized edge. Nitrogen, by contrast, is inert and produces a bright, oxide-free edge that is especially important for visible components, although it is more expensive. Compressed air is sometimes used for less demanding applications where cost savings outweigh the need for premium edge quality. For polished or reflective stainless steels, nitrogen is almost always preferred to avoid discoloration and preserve surface finish.

Post-Cut Handling and Finishing

The final step is post-cut handling and finishing. Although stainless steel cools relatively quickly, thicker sections may require controlled cooling to avoid warping. Small burrs along the cut edges are removed mechanically through brushing, grinding, or tumbling. If oxygen is used during cutting, oxide residue is often present and must be cleaned to restore the metal’s natural appearance. For parts destined for food processing or medical applications, chemical passivation is performed to re-establish the protective chromium oxide layer on the stainless steel surface. This ensures the component not only looks clean but also maintains its corrosion resistance and mechanical performance in demanding environments.

Types of Lasers Used for Cutting Stainless Steel

Choosing the right laser is crucial – it’s like picking the right tool for a job. For stainless steel, fiber laser cutting dominates due to its efficiency on reflective metals.

| Wavelength | Best for Stainless Steel Thickness | Pros | Cons | |

| Fiber | ~1μm | Up to 25mm | High speed, low maintenance, excellent for reflective steels | Higher upfront cost |

| CO2 | ~10μm | Up to 3mm | Affordable for thin sheets; good for non-metals too | Poor absorption of shiny stainless requires more power |

| Nd:YAG | ~1μm | Up to 20mm | Versatile for welding/cutting | Less efficient, higher energy use |

Fiber lasers excel because their wavelength matches stainless steel’s absorption profile, cutting 2-3 times faster than CO2 on a 5mm sheet. In my experience with automotive parts, switching to fiber reduced edge roughness by 40%. Emerging ultrafast lasers (with picosecond pulse durations) are revolutionizing micro-feature processing by minimizing the HAZ to below 10 μm, making them ideal for precision medical devices.

Laser Cutting Parameters for Stainless Steel

Getting the right cut depends on optimizing power, speed, and gas.

Power Settings vs Thickness

The amount of laser power required depends directly on the thickness of the stainless steel sheet. Using too little power risks incomplete cuts, while too much power can cause excessive heat, leading to rough edges and a wider heat-affected zone.

| Thickness | Recommended Power | Gas | Speed (m/min) |

| 1 mm | 500–1000 W | N2 | 6–12 |

| 3 mm | 1500–2000 W | N2/O2 | 3–5 |

| 6 mm | 2000–3000 W | O2 | 1–3 |

| 10 mm | 3000–6000 W | N2 | 0.8–1.5 |

| 20+ mm | 8–12 kW fiber laser | N2 | 0.2–0.8 |

Assist Gases

The choice of assist gas plays a critical role in cut quality and efficiency. Different gases not only influence cutting speed but also determine whether the final edge is clean, oxidized, or suitable for visible applications.

- Oxygen: faster cuts, slightly oxidized edge.

- Nitrogen: oxidation-free, cleaner finish (preferred for visible parts).

- Air: cost-effective, but quality varies.

Speed & Focus Considerations

Cutting speed and focal point positioning must be carefully optimized for stainless steel. If either is misaligned, the result can be dross buildup, poor edge quality, or even failed cuts.

- Too slow → excess heat, wider HAZ.

- Too fast → incomplete cuts.

- Proper focus → narrow kerf and minimal dross.

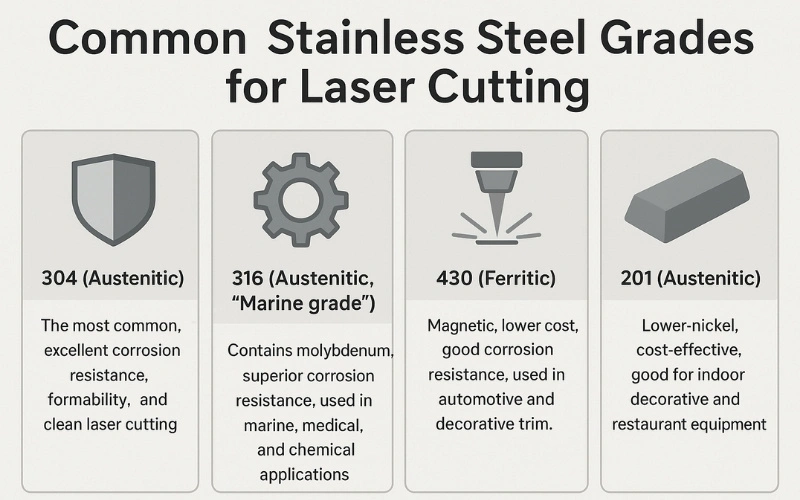

Common Stainless Steel Grades for Laser Cutting

Stainless steel is a broad category. Different grades have different alloying elements, which affect their mechanical properties and how they interact with the laser. Fortunately, most common grades cut exceptionally well.

- 304 (Austenitic): This is the workhorse of the stainless steel world, accounting for over 50% of all stainless steel used. Its excellent blend of corrosion resistance, formability, and value makes it a top choice for everything from kitchen appliances to architectural trim. It laser cuts beautifully with a clean and predictable result.

- 316 (Austenitic): Often referred to as “marine grade”, 316 contains molybdenum, which provides it with superior corrosion resistance, particularly against chlorides and industrial solvents. It’s used in marine hardware, medical implants, and chemical processing equipment. Its cutting properties are very similar to 304.

- 430 (Ferritic): This is a magnetic, lower-cost grade with good corrosion resistance, often used in decorative applications, automotive trim, and appliance paneling. It laser cuts very well, though operators may need to adjust parameters slightly compared to 300-series grades.

- 201 (Austenitic): A lower-nickel, lower-cost alternative to 304, this grade is used in applications where high corrosion resistance isn’t the primary concern, such as indoor decorative elements and restaurant equipment. It cuts cleanly and efficiently with a laser.

Advantages of Choosing Laser Cutting for Stainless Steel

Stainless steel is a famously tough and resilient material. While it can be cut with other methods, laser cutting offers a unique combination of benefits that make it the superior choice for a vast range of applications.

- Unmatched precision and Intricate detail: Laser beams can be focused down to a spot size of less than 0.25 mm. This allows for the creation of incredibly complex geometries, sharp corners, and fine features that are impossible to achieve with most other cutting methods. We routinely hold tolerances as tight as ±0.1 mm, ensuring parts fit together perfectly in complex assemblies.

- Superior edge quality: When performed correctly, laser cutting produces an exceptionally smooth, clean, and burr-free edge. This high-quality finish often eliminates the need for secondary processing like deburring or grinding, saving significant time and labor costs in the production workflow.

- High-speed production: For thin to medium-gauge stainless steel (up to 20m/min), fiber laser cutting is significantly faster than traditional machining methods (30% faster than plasma). The CNC-controlled process is automated and can run at high speeds, making it ideal for both rapid prototyping and high-volume production runs.

- Non-contact process: With laser cutting, only a laser beam touches the material, so there’s no tool wear. This saves on the costs and downtime of replacing and sharpening tools. The non-contact process also puts minimal stress on the material, and the highly focused heat creates a small heat-affected zone (HAZ), which reduces the risk of warping.

- High material efficiency: The laser kerf (the width of the material removed) is extremely narrow. This allows for “tight nesting,” where parts can be arranged very close to each other on the sheet of raw material. This maximizes the number of parts produced per sheet and significantly reduces costly material waste.

Laser Cutting vs Other Methods: Which is Better?

To make an informed decision for your project, it’s crucial to know how laser cutting stacks up against its main competitors for cutting stainless steel.

| Laser | Plasma | Waterjet | |

| Precision | High (±0.1 mm) | Medium | Very high |

| Max Thickness | Up to 30 mm | Up to 80 mm | >100 mm |

| Speed | Fast | Fast | Slow |

| Cost | Medium-high | Medium | High |

| Edge Quality | Clean, minimal burrs | Rougher edge | No heat zone |

Conclusion

Laser cutting stainless steel has become the gold standard for precision fabrication across industries. With its ability to deliver accurate, efficient, and clean cuts, it outperforms traditional methods in most scenarios. While challenges such as burrs, discoloration, and cost exist, they can be managed with the right parameters and technology. For businesses and engineers, understanding the process, material suitability, and service provider selection ensures the best outcomes.

FAQs

Yes, the localized heat can slightly harden the edge of stainless steel by altering its microstructure. However, with optimized parameters, this effect is minimal and usually does not impact performance for most applications.

Yes, CO2 lasers can cut stainless steel, but they are less efficient and slower compared to fiber lasers, especially with reflective or thicker materials. Fiber lasers are generally recommended.

A high-power fiber laser (typically 2–6 kW, or up to 12 kW for thicker sheets) is the most effective choice for cutting 304 stainless steel, providing clean edges and high precision.