Laser cutting has revolutionized modern manufacturing, offering unmatched precision, speed, and flexibility for a wide range of industries. Whether you’re an engineer, a business owner, or a curious learner, understanding laser cutting is essential for staying ahead in today’s competitive market. In this comprehensive guide, we’ll explore everything you need to know about laser cutting, from the basics to advanced applications, safety, and how to choose the right service provider in Vietnam.

What is Laser Cutting?

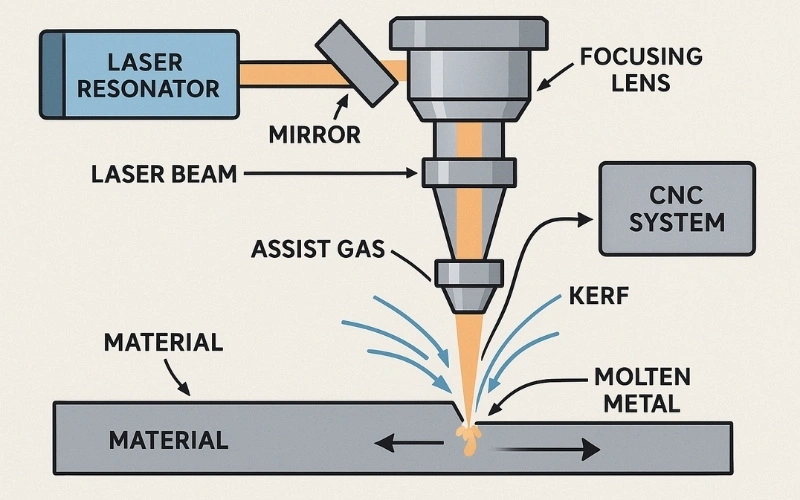

Laser cutting is a high-precision fabrication method that utilizes a concentrated, high-intensity laser beam to cut, engrave, or sculpt materials such as metal, plastic, and wood. Controlled by CNC systems and optics, the laser follows a digital design, melting or vaporizing the target area to create clean, narrow cuts with minimal distortion. This thermal process is essential in manufacturing, the automotive industry, and electronics for its speed, accuracy, and ability to handle complex patterns. Compared to mechanical or plasma cutting, it offers greater precision and reduces material waste.

Read more: Laser Tube Cutting: Technology, Challenges, Best Design Practices

How does the Laser Cutting Process Work?

Understanding the laser cutting process helps you appreciate its precision and versatility. Here’s a step-by-step breakdown:

Laser Generation

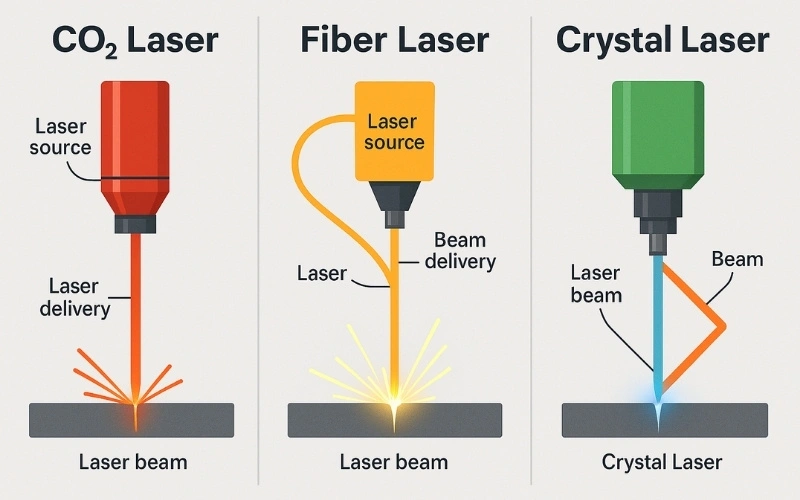

The process begins with the generation of the laser beam itself. Inside the laser cutting machine, energy (typically electrical) is used to stimulate a lasing medium, which could be a gas like CO2, a fiber-optic cable doped with rare-earth elements, or a crystal such as Nd:YAG or Nd:YVO₄. This stimulation causes the medium to emit photons, or light particles, in a coherent, monochromatic beam. The laser is amplified in a resonator cavity and eventually exits as a powerful, focused stream of light.

Different laser sources offer different strengths: CO2 lasers are versatile and cost-effective for cutting non-metals, while fiber lasers provide superior energy efficiency and are particularly effective for cutting reflective metals such as aluminum or brass. The power and stability of the generated beam are foundational to the success of the entire cutting operation.

Beam Shaping and Focusing

After the laser beam is generated, it must be precisely shaped and directed toward the cutting surface. This is achieved through a system of mirrors and lenses that guide the beam along a predetermined path. The beam delivery system channels the laser through a focusing lens (usually a plano-convex or zinc selenide lens), which concentrates the beam into a tight focal point with a diameter as small as 0.1 millimeters. At this point, the beam’s intensity can reach tens of thousands of watts per square centimeter, allowing it to melt or vaporize most materials instantly. The focal point is carefully aligned with the surface of the workpiece to ensure optimal energy transfer and cutting accuracy. Any deviation in focus can result in wider kerfs, poor edge quality, or incomplete cuts, making this step one of the most critical in the entire process.

Material Interaction (Melting, Burning, or Vaporizing)

Once the beam is focused, it begins interacting directly with the material. The intense heat energy at the focal point raises the temperature of the workpiece to its melting, burning, or vaporization point, depending on the material’s properties and the beam’s power density. For metals, the process usually involves melting the surface, which then flows away from the cut zone. For organic materials like wood or acrylic, the beam may burn or sublimate the material directly. The interaction is fast and localized, which allows for narrow cuts with minimal heat-affected zones. This precision is particularly valuable in industries where micro-tolerances and material integrity are paramount, such as aerospace, medical device manufacturing, and microelectronics. Proper material interaction also ensures smooth edges and reduces the need for secondary finishing processes.

Assist Gas Ejection

To enhance the cutting performance and maintain a clean working surface, an assist gas is directed at the cutting area through a coaxial nozzle surrounding the laser beam. This gas serves several purposes: it blows away molten or vaporized material from the kerf (the channel created by the laser), prevents the formation of slag, and cools the surrounding area to reduce thermal distortion. The choice of gas depends on the material and the desired finish.

Oxygen is often used for cutting carbon steel because it supports combustion and increases cutting speed through an exothermic reaction. Nitrogen is preferred when an oxidation-free finish is required, especially in stainless steel and aluminum cutting. Compressed air is sometimes used as a cost-effective option for less demanding jobs. The pressure, purity, and flow rate of the assist gas must be precisely controlled, as these factors directly impact cut quality, edge smoothness, and operational efficiency.

Motion Control and Execution

The final step in the laser cutting process involves the precise movement of the laser head over the material surface, guided by a computer numerical control (CNC) system. This system interprets digital design files (typically in formats like DXF or SVG) and translates them into coordinates and motion commands. The laser cutter follows these instructions with exceptional accuracy, moving along the X, Y, and sometimes Z axes, depending on the machine’s configuration. In advanced systems, rotary attachments enable cylindrical or angled cuts. The synchronization of beam emission with head movement ensures consistent cut depth and edge quality.

Furthermore, modern laser cutters often feature automatic focus adjustment, real-time monitoring, and adaptive speed controls, which together optimize performance across a wide range of materials and thicknesses. At this stage, the design is faithfully reproduced in the material, completing the transformation from digital blueprint to tangible product.

Types of Laser Cutting Technologies

The term “laser” isn’t one-size-fits-all. The type of laser technology used dictates what materials can be cut, how fast they can be cut, and the quality of the final edge. Understanding these differences is essential for choosing the right service or machine for your project.

CO2 Laser

CO2 laser cutting is one of the earliest and most common types. They generate their beam using an electricity-stimulated gas mixture, primarily composed of carbon dioxide. Because of their specific wavelength of light, CO2 lasers are incredibly versatile. They are the go-to choice for cutting a wide range of organic and non-metallic materials, including wood, acrylic, leather, paper, fabric, and foam. They can also cut thinner metals, but they do so less efficiently than their fiber counterparts.

Fiber Laser

Fiber laser cutting represents a newer, solid-state technology that has taken the metal fabrication industry by storm. They create their laser beam within a specialized optical fiber that has been “doped” with rare-earth elements. This process is significantly more efficient than CO2 gas excitation, resulting in much lower power consumption and operating costs. Fiber lasers have a shorter wavelength that is readily absorbed by metals, making them exceptionally fast and precise for cutting steel, stainless steel, aluminum, brass, and copper. Their solid-state design also means they have fewer moving parts and require minimal maintenance, making them a staple in high-production environments.

Crystal Laser (Nd:YAG and Nd:YVO)

Crystal lasers, also known as solid-state lasers, use a crystal (such as Neodymium-doped Yttrium Aluminum Garnet – Nd:YAG) as their lasing medium. These lasers can deliver extremely high peak power, which makes them suitable for cutting and engraving very thick, tough materials, including metals and ceramics. While powerful, they are generally less efficient and require more maintenance than fiber lasers, so they are typically reserved for more specialized, high-power applications where the capabilities of CO2 and fiber lasers fall short.

To make the choice clearer, here is a detailed comparison:

| CO2 Laser | Fiber Laser | Crystal Laser | |

| How it works | Electrically stimulated gas mixture | Diode-pumped doped optical fiber | Diode-pumped crystal medium |

| Best for | Organic materials (wood, acrylic, paper), plastics, leather | Metals (all types), some plastics | Thick metals, ceramics, high-power marking |

| Key advantage | Unmatched versatility, excellent edge quality on organic materials | Incredible speed & efficiency on metals, low maintenance | Extremely high peak power for tough materials |

| Key disadvantage | Lower electrical efficiency, slower on metals, requires gas refills | Poor performance with most organic materials | Higher maintenance costs, lower efficiency than fiber |

| Wavelength | Long (~10,600 nm) | Short (~1,060 nm) | Short (~1,064 nm) |

What Materials Are Used in Laser Cutting?

The success of any laser cutting project hinges on selecting the right material. A laser’s interaction with a material can range from a perfectly clean cut to melting, charring, or even the release of hazardous gases. This section serves as your reference guide. Below is a detailed table of common materials, their suitability for laser cutting, and crucial considerations. Most importantly, it includes materials you should NEVER attempt to cut due to extreme safety risks.

Metals

Fiber lasers have opened the door to rapid and precise metal fabrication.

- Steel (Mild & Carbon): Cuts quickly and cleanly, especially with the aid of an oxygen-assist gas.

- Stainless Steel: Cuts beautifully with a nitrogen assist gas to produce a clean, oxide-free edge ready for welding.

- Aluminum: Using aluminum in laser cutting can be tricky due to its reflectivity, but modern fiber lasers handle it with ease.

- Brass & Copper: Also highly reflective, but fiber lasers are very effective.

Note: The thickness and type of metal are the biggest factors in determining cutting speed and power requirements.

Read more: What is metal laser cutting and how does it work?

Plastics

CO2 lasers are masters of plastic fabrication.

- Acrylic (Plexiglass, Lucite): One of the most popular materials. The laser melts the edge as it cuts, resulting in a beautiful, flame-polished finish.

- POM (Delrin): An engineering plastic that cuts very cleanly with little burring.

- Mylar: Often used for stencils, it cuts with extreme precision.

Note: Different plastics react differently. Some melt cleanly, while others can char or produce fumes, requiring proper ventilation.

Wood & Organics

CO2 lasers also excel with natural materials.

- Plywood, MDF, Hardwoods: Cut with a characteristic charred edge, which can be a desirable aesthetic. The results are highly dependent on the wood’s density and resin content.

- Leather: Cuts and engraves beautifully for products like wallets, belts, and patches.

- Paper & Cardboard: Can be cut with incredible intricacy at very high speeds for applications like custom invitations or packaging prototypes.

Critical Safety Warning: Materials to Never Laser Cut

Cutting the wrong materials can release toxic, corrosive gases and permanently damage your machine and, more importantly, your health. Here are some materials that you must never use in laser cutting:

- Polyvinyl Chloride (PVC): This includes vinyl, Sintra, and other PVC-based materials. When heated, it releases pure chlorine gas, which is deadly to humans and will instantly corrode the metal components of your laser cutter.

- Polycarbonate (PC): While strong, polycarbonate does not cut well. It absorbs the laser’s infrared radiation inefficiently, causing it to discolor, melt, and often catch fire.

- ABS (Acrylonitrile Butadiene Styrene): A common 3D printing material, ABS melts rather than vaporizes, leaving a messy, gummy edge. It also releases cyanide gas when cut.

- Coated Carbon Fiber: Thin, uncoated carbon fiber can be cut, but any coated or thick carbon fiber releases a host of toxic fumes.

- HDPE (Milk Jug Plastic): Tends to melt and catch fire, creating a significant hazard.

CRITICAL SAFETY NOTE: Attempting to laser cut prohibited materials, especially those containing chlorine like PVC, can release highly toxic and corrosive gases (such as chlorine gas and hydrochloric acid). These fumes can cause severe, permanent respiratory damage and will irreparably corrode the machine’s optics, mechanics, and electronics. Always verify your material’s composition before cutting.

Advantages and Disadvantages of Laser Cutting

No manufacturing process is perfect for every situation. A trustworthy evaluation requires an honest look at both the strengths and weaknesses. For those in the commercial investigation phase, this balanced view is critical for making an informed decision.

Key Advantages

- Unmatched Precision and Detail: Lasers can achieve incredibly high tolerances (+/- 0.1 mm or better) and cut extremely intricate and complex geometries that would be impossible with traditional cutting tools.

- High Speed and Repeatability: For many materials, especially thin sheet metal, laser cutting is exceptionally fast. As a CNC-driven process, it can also produce thousands of identical parts with perfect consistency, making it ideal for mass production.

- Non-Contact Process: The laser beam does not physically touch the material. This means there is no tool wear (unlike blades or drill bits), and it minimizes the risk of material warping or contamination, as no mechanical force is being applied.

- Incredible Material Versatility: As seen in the table above, a single laser cutting shop with both CO2 and Fiber machines can process a massive range of materials, from steel and aluminum to acrylic and wood, to leather and fabric.

- Automation and Efficiency: The process is highly automated, requiring minimal labor once a job is set up. Designs can be sent directly from a computer to the cutter, allowing for rapid prototyping and on-demand production, which reduces lead times and inventory costs.

Key Disadvantages

- High Upfront Equipment Cost: Industrial laser cutters are significant capital investments, often costing hundreds of thousands of dollars. This is a major barrier to entry for smaller shops and is why many businesses opt to use laser cutting services instead of purchasing a machine.

- Limitations on Material Thickness: While lasers can cut very thick materials, the process becomes much slower and less efficient as the thickness increases. For very thick plates of metal (like >25mm), other methods such as plasma or waterjet cutting are often more economical.

- Challenges with Reflective Materials: Metals like copper, brass, and polished aluminum are highly reflective. This can cause the laser beam to bounce back into the machine’s optics, potentially causing damage. It requires specialized equipment and expertise to cut these materials reliably.

- Hazardous Fumes and Safety Requirements: The vaporization of materials creates fumes and particulates that can be toxic. This necessitates a robust ventilation and filtration system. Furthermore, high-power lasers pose a severe eye and fire hazard, requiring a controlled environment and strict safety protocols.

- Heat-Affected Zone (HAZ): Because it is a thermal process, laser cutting creates a small area along the cut edge where the material’s properties have been altered by the heat. While this HAZ is typically very small, it can be a concern for certain high-stress engineering applications that require post-processing to remove it.

Design Practices for Laser Cutting

Creating a great design for a laser cutter is about more than just drawing lines. It requires thinking like a machine. By understanding a few key concepts, you can avoid common pitfalls and ensure your parts come out perfectly, whether you’re a professional designer or a weekend hobbyist. This section is based on real-world experience.

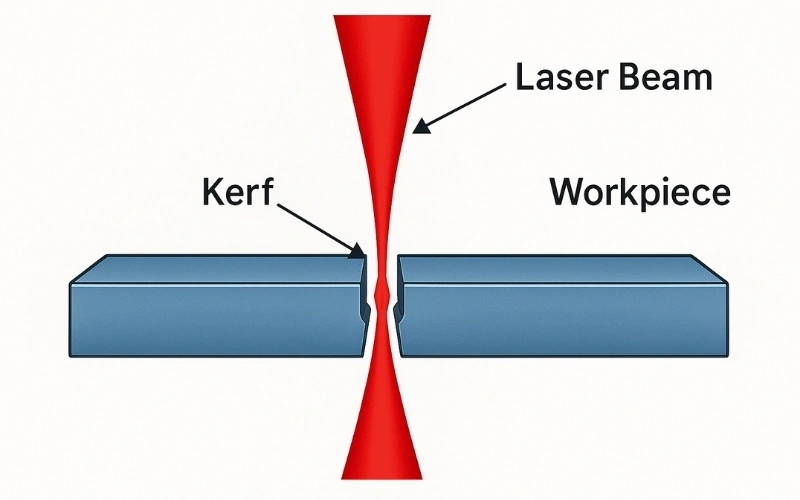

Understanding Kerf (The Laser’s Width)

The laser beam isn’t infinitely thin; it has a physical width, and the material it removes is called the kerf. This is a critical concept for any parts that need to fit together. For example, if you design a 10mm wide peg to fit into a 10mm wide hole, it won’t fit. The laser will remove a small amount of material from the edge of both parts, making the peg slightly smaller and the hole slightly larger.

Practical Tip: To compensate for kerf, you must adjust your design. A good laser cutting service will know their machine’s kerf (it’s often around 0.1mm – 0.2mm). For a snug fit, you might design the hole to be slightly smaller (e.g., 9.9mm) to account for the material that will be vaporized. Always do a small test cut with your chosen material to confirm the exact kerf before running a large job.

Vector vs Raster: Cutting vs Engraving

Your design software will use two types of imagery, and the laser interprets them differently.

- Vector: A vector is a path defined by mathematical points (like in Adobe Illustrator or AutoCAD). The laser follows this path precisely, like a knife, to cut through the material. Lines for cutting should be set to a specific, very thin stroke weight (e.g., 0.01mm or a hairline).

- Raster: A raster is a pixel-based image (like a JPEG or PNG). The laser reads this image like a printer, moving back and forth line by line and firing the laser at varying power levels to etch or engrave the surface of the material without cutting through.

File Formats and Best Practices

To ensure your design is interpreted correctly by the machine, follow these universal best practices:

- Common File Formats: DXF and DWG are the gold standards for 2D CAD. AI (Adobe Illustrator) and SVG (Scalable Vector Graphics) are also widely accepted.

- Use Closed Paths: All shapes intended for cutting must be a continuous, closed loop. If there is a tiny gap in a circle’s outline, the machine won’t know where to stop and start.

- Remove Duplicate Lines: If you have one line drawn directly on top of another, the laser will cut the same path twice. This will result in a wider kerf, a poor edge finish, and an increased fire risk.

- Convert Text to Outlines: The laser cutter’s computer won’t have your specific font installed. You must convert all text into vector shapes (an option often called “Create Outlines” or “Convert to Curves”) before saving.

Crucial Safety Precautions (YMYL Focus)

This is the most important section of this part. Lasers are powerful tools, not toys. Whether you are using a desktop machine or an industrial one, your safety and the safety of those around you are the absolute top priority. This is non-negotiable. You must remember that “Safety is paramount; always follow these rules.”:

- NEVER Leave the Laser Unattended: This is the number one rule. Materials, especially wood and acrylic, can and do catch fire. You must be present to immediately stop the machine and extinguish any flames.

- Use Proper Fume Extraction: As discussed, cutting materials creates fumes. A proper ventilation system that exhausts to the outside or a certified carbon filtration unit is mandatory to protect you from breathing in toxic and carcinogenic particles.

- Know Your Materials: Refer back to the materials table. Never guess. Cutting forbidden materials like PVC can release deadly gases and destroy your machine.

- Use Certified Laser Safety Glasses: The laser’s light, even if reflected, can cause permanent, instant blindness. You must wear safety glasses specifically rated for the wavelength of your laser (CO2 and Fiber require different glasses). Standard safety glasses offer zero protection.

- Keep a Fire Extinguisher Nearby: A CO2 fire extinguisher is essential and should be within arm’s reach of the machine at all times.

How to Choose the Right Laser Cutting Partner?

Choosing a laser cutting partner isn’t just about price – it’s about reliability, precision, and support. Here are the key features to evaluate before making a decision:

- Laser Technology Used: Choose providers with the right equipment for your material (such as fiber lasers for metal, CO2 for acrylic or wood). Ask about machine brands (e.g., TRUMPF, Bystronic).

- Material Compatibility: Ensure they can cut your required material and thickness. Request sample cuts to verify quality.

- Certifications & Standards: Look for ISO 9001:2015 or other relevant industry certifications, especially for regulated sectors like medical, aerospace, or automotive.

- Cutting Precision & Tolerances: Ask about achievable tolerances and edge finish. High-end services should offer tight tolerances (±0.1 mm or better).

- Turnaround Time: Inquire about standard lead times, rush order capabilities, and delivery options. Local vendors may offer faster logistics.

- Transparent Pricing: Request detailed quotes that include setup fees, per-part costs, and optional services (deburring, engraving). Avoid vague or inconsistent pricing.

- Customer Support: Choose partners who offer responsive communication and DFM (Design for Manufacturability) feedback. This reduces costly revisions.

Laser Cutting Service in Vietnam

Vietnam has become a growing hub for precision manufacturing, and laser cutting services in the country are no exception. With a rapidly developing industrial base and increasing investment in smart manufacturing, many Vietnamese providers now offer high-quality laser cutting services for both domestic and international clients. Whether you are a startup prototyping a product, a design firm working on interior fittings, or an exporter looking for mass production support, the local market offers a wide range of options.

ABC Vietnam is a leading company that offers high-quality laser cutting services in Vietnam. We specialize in laser cutting sheet and tube components (tubes, channels, angles, and structural shapes in any size and shape, using our 3D laser tube cutting machine). With over 20 years of experience in sheet metal fabrication, especially in laser cutting, combined with excellent customer support and on-time delivery, we are the most reliable company for your laser-cut projects. Contact us now to discuss your project!

Conclusion

Laser cutting is more than just a manufacturing process; it’s an enabling technology. It bridges the digital and physical worlds with a level of speed, precision, and versatility that was once unimaginable. From industrial manufacturing to personal creativity, the laser cutter has become an indispensable tool for turning ideas into reality. Try a DIY project or explore our professional services. What will you create? Feel free to share your ideas with us!

FAQs

The cost varies significantly based on several factors: the type and thickness of the material, the total cutting time (which is determined by the complexity and length of the cut paths), and the quantity of parts being ordered. Simple designs on cheap materials can cost only a few dollars, while complex parts from exotic metals can be much more. Most services offer instant online quotes.

Generally, no. Standard laser cutters cannot cut glass effectively. The thermal shock tends to fracture the material rather than produce a clean cut. Specialized processes are required for glass. However, lasers can be used to etch the surface of glass beautifully.

You need 2D vector design software. Popular professional choices include AutoCAD (for DXF/DWG files) and Adobe Illustrator (for AI/SVG files). Free and open-source options like Inkscape (SVG) and QCAD (DXF) are also excellent and widely used by hobbyists and professionals alike.

This depends entirely on the laser’s power and the material. A low-power hobbyist CO2 laser might cut up to 6mm (1/4″) of wood. A high-power industrial fiber laser can cut through 25mm (1″) of steel or even thicker. Refer to the materials table above for general guidelines.