Laser cutting aluminum is a staple process in modern manufacturing due to its precision, speed, and ability to work with complex geometries. However, aluminum presents unique challenges compared to other metals, demanding specialized knowledge, machine capabilities, and experience to master. In this comprehensive guide, we’ll walk you through everything you need to know, from understanding the physics of cutting aluminum to selecting the right alloy, machine settings, and post-processing steps.

What is Laser Cutting for Aluminum?

Laser cutting is a precise, non-contact thermal process that uses a high-powered, focused laser beam to melt, burn, or vaporize materials, producing clean, detailed cuts. When working with aluminum, the process becomes more challenging due to the metal’s high reflectivity, thermal conductivity, and natural oxide layer, which can impact laser absorption and edge quality. To address these factors, manufacturers often use fiber lasers or short-pulse laser systems, which are better suited for cutting reflective metals.

Read more: What is Metal Laser Cutting?

This technology is widely applied in industries such as aerospace, automotive, and architectural signage, where dimensional accuracy and minimal heat distortion are critical. By adjusting key laser parameters such as cutting speed, pulse frequency, and assist gas pressure, operators can reduce dross formation and achieve smooth, consistent edges. Compared to mechanical cutting, laser profiling offers faster, contactless processing for both thin aluminum sheets and thicker alloys, improving efficiency and part quality.

The Process of Laser Cutting Aluminum

Laser cutting aluminum is a step-by-step operation that requires careful calibration and execution. Each stage plays a vital role in achieving a high-quality result, and understanding these steps helps manufacturers fine-tune their workflows and reduce waste.

Material Preparation

Before cutting begins, the aluminum sheet must be properly prepared. This includes cleaning the surface to remove oil, dirt, or oxide buildup, which can interfere with laser absorption. Ensuring a flat, even sheet also helps maintain focus, consistency, and cut quality.

CAD Design and Nesting

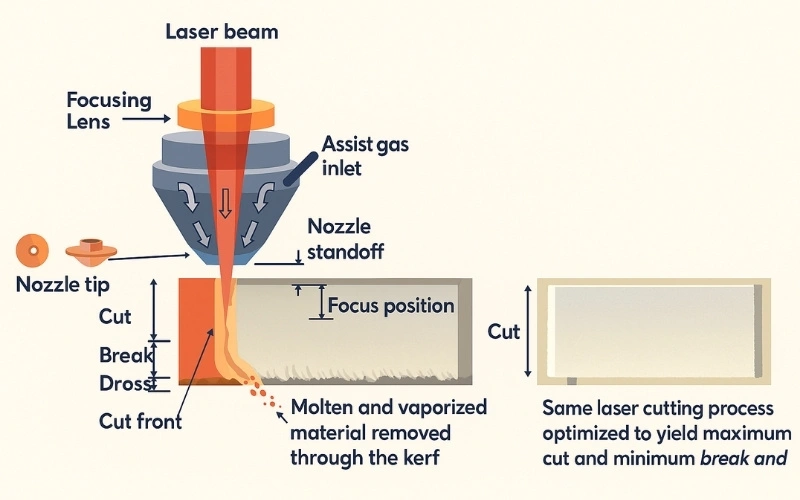

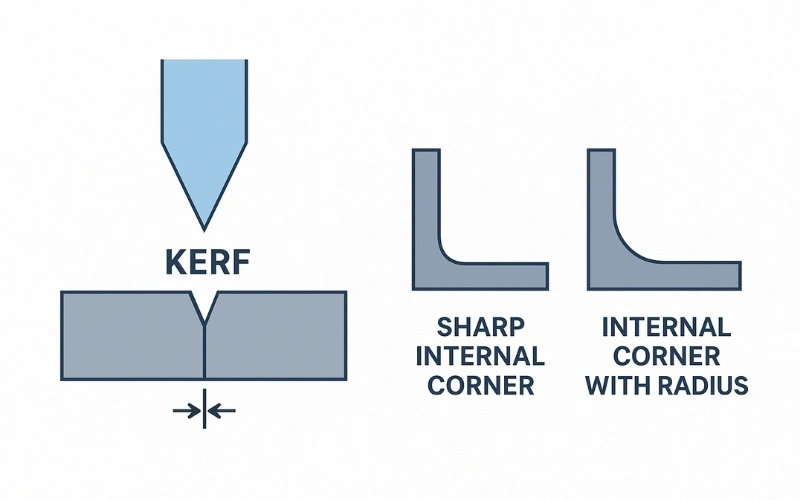

The process starts digitally with CAD (Computer-Aided Design) software, where the part’s dimensions and contours are drawn. These designs are then nested, arranged efficiently on a sheet layout to minimize material waste and optimize cutting time. This stage may also involve compensating for the laser kerf (width of the cut).

Parameter Configuration

Based on the material thickness and alloy, the operator sets parameters such as laser power, cutting speed, frequency, and assist gas type and pressure. This step ensures the laser interacts with the material effectively and produces a clean cut. These settings are often stored in a library for common material combinations.

Laser Focusing and Alignment

Before execution, the laser head must be properly focused to deliver maximum energy density at the cut point. Misalignment can lead to incomplete cuts, dross, and inefficient processing. Advanced systems may include auto-focus or capacitive height sensing for consistency.

Cutting Execution

Once everything is set, the laser begins the cutting process. The beam melts or vaporizes the material while the assist gas (usually nitrogen or oxygen) blows molten particles away from the cut. The nozzle follows the programmed path with high precision, enabling the creation of complex geometries and achieving tight tolerances.

Real-Time Monitoring and Adjustment

During cutting, operators monitor for inconsistencies such as sparks, dross formation, or edge discoloration. In some advanced systems, sensors automatically adjust speed or power in response to material feedback. Manual monitoring is especially important when working with variable-thickness sheets.

Cooling and Sheet Removal

After cutting is complete, the aluminum sheet cools rapidly. Operators inspect the parts before removing them to ensure clean separations and identify any potential issues. Loose dross or burrs may still be attached and can be cleaned in the next step.

Post-Processing and Finishing

The last stage includes deburring, edge smoothing, and sometimes surface treatments like anodizing or painting. This step ensures the final part meets aesthetic and functional requirements, especially in aerospace or architectural applications.

Types of Lasers for Cutting Aluminum

Understanding the challenges of reflectivity and conductivity makes the choice of technology clear. Not all lasers are created equal, and for this specific application, the difference is night and day.

Fiber Laser

The breakthrough in cutting aluminum came with the commercialization of high-power fiber laser cutting. Here’s why they work so effectively:

- Optimal Wavelength: Fiber lasers operate at a much shorter wavelength, typically around 1.06 µm. Aluminum absorbs this wavelength up to ten times more efficiently than the longer wavelength of a CO2 laser. More energy is absorbed, less is reflected, and the cutting process becomes stable and efficient.

- High Power Density: Fiber lasers can focus their beam into a much smaller spot size. This creates an extremely high power density, a massive amount of energy concentrated in a tiny area. This intense energy instantly vaporizes the material, initiating the cut before the heat has a chance to dissipate, perfectly overcoming the thermal conductivity challenge.

For any serious, repeatable cutting of aluminum, a fiber laser with a power of at least 1kW (1000 watts) is the industry-standard starting point.

CO2 and Diode Laser

This is a point of frequent confusion and a critical safety warning. If you own a hobby-grade or prosumer-level laser, you must remember that:

STANDARD CO2 AND DIODE LASERS CANNOT CUT ALUMINUM

These machines lack both the correct wavelength to be absorbed effectively and the raw power density to overcome the material’s thermal conductivity. At best, the beam will reflect off the surface, doing nothing. At worst, the reflected energy can travel back up into the laser’s focusing lens and machine head, causing catastrophic and expensive damage.

However, there is a silver lining. While they can’t cut it, these lasers can be used to mark or engrave aluminum. To do this, the surface must first be coated with a special laser-marking spray or paste. The laser then heats this coating, bonding it permanently to the aluminum surface to create a dark, durable mark. You can also effectively etch or engrave anodized aluminum, where the laser ablates the colored dye layer to reveal the raw aluminum beneath.

How to Choose the Right Aluminum Alloy for Laser Cutting?

Not all aluminum is the same. Aluminum alloys are categorized into series, each with different elements that impart unique properties. Some are ideal for laser cutting, while others can be more challenging. Selecting the right alloy is a critical step in the design process. Here’s a breakdown of the most common laser-cut alloys:

| Key properties | Laser cut ability | Common applications | |

| 5052-H32 | Excellent formability, high fatigue strength, superb resistance to marine corrosion | Excellent | Marine components, electronic chassis, fuel tanks, sheet metal enclosures |

| 6061-T6 | General sheet metal work, fan blades, cooking utensils, and architectural siding | Very good | Structural components, base plates, machine parts, bicycle frames |

| 3003-H14 | Excellent formability and workability, moderate strength, good corrosion resistance | Excellent | General sheet metal work, fan blades, cooking utensils, and architectural siding |

| 1100-H14 | Commercially pure aluminum. Highly ductile, excellent corrosion resistance, low strength | Good | Often used where high electrical or thermal conductivity is required. Can be “gummy” to cut |

With our experience, the 5xxx and 6xxx series alloys provide the most consistent and high-quality results when laser cut.

Why Is Aluminum Challenging to Cut with Lasers?

Laser cutting aluminum involves several technical challenges that distinguish it from cutting steel or other metals. Below are the key reasons why precision and care are essential.

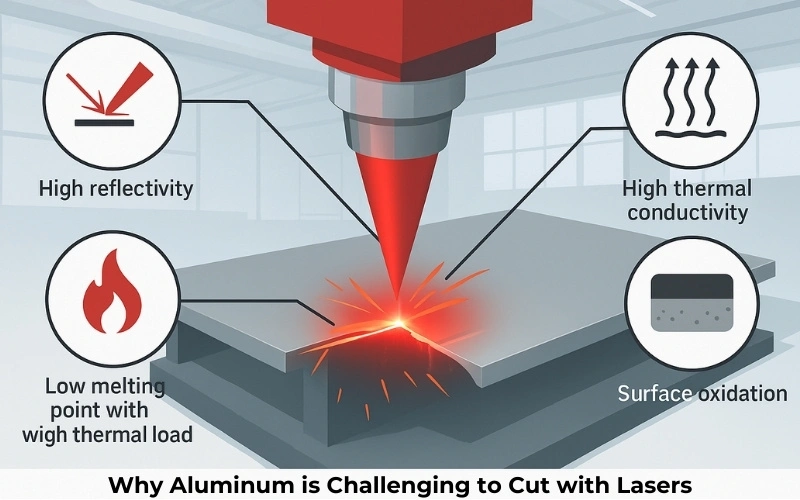

High Reflectivity

Aluminum exhibits high reflectivity for infrared wavelengths, particularly those used in CO2 lasers. When the laser beam encounters the aluminum surface, a significant portion of the energy is reflected rather than absorbed. This not only reduces cutting efficiency but also introduces the risk of back-reflection, which can damage expensive laser components like lenses and mirrors. Due to their 1.06 µm wavelength, which is more readily absorbed by the metal, fiber lasers are better suited for cutting aluminum. To mitigate reflection risks, advanced systems use back-reflection sensors and optical isolators to protect internal components.

High Thermal Conductivity

Aluminum’s high thermal conductivity means that heat from the laser disperses quickly throughout the material. This rapid heat dissipation prevents the cutting zone from maintaining the high temperatures required for continuous and clean cuts. As a result, operators often need to increase laser power and decrease cutting speed to concentrate heat on the targeted area. Keeping the beam tightly focused and minimizing the distance between the nozzle and the material can help limit heat loss, ensuring a more consistent and deeper cut.

Low Melting Point with High Thermal Load

Although aluminum has a relatively low melting point of 660°C, its excellent thermal conductivity means the heat doesn’t stay localized. This creates a thermal imbalance where localized melting may occur inconsistently or cause blowouts in thinner materials. The combination of low melting temperature and high thermal load demands careful control of power levels. Pulse mode or ramping power input gradually can provide better control and prevent overheating or burn-through, especially in thin sheets.

Dross and Burr Formation

When aluminum is not cut under optimal conditions, it often produces dross (hardened particles of molten material that stick to the underside of the cut). Burrs, or jagged metal edges, can also form along the cut line. These imperfections affect the part’s appearance and may require additional post-processing. Using nitrogen as an assist gas helps minimize oxidation and blow away molten material cleanly. Fine-tuning the gas pressure, nozzle height, and cutting speed can significantly reduce the occurrence of dross and burrs.

Surface Oxidation

Aluminum naturally forms a thin layer of aluminum oxide when exposed to air. This oxide layer has a melting point of about 2,000°C, much higher than the base aluminum. This difference makes it difficult for the laser to initially penetrate the surface, especially in anodized or recycled aluminum. To address this, it’s essential to pre-clean the aluminum surface and apply a high-peak-power pulse at the beginning of the cut to break through the oxide layer effectively. This ensures a smoother, more consistent cutting experience.

Design for Manufacturing (DFM) Principles

A perfect part starts with a perfect design file. As an engineer or designer, understanding the nuances of the laser cutting process allows you to optimize your CAD files for better results, lower costs, and faster turnaround times. This is known as Design for Manufacturing (DFM).

| Design rule | Recommendation | Why does it matter? |

| Kerf Allowance | Assume a kerf of ~0.1mm – 0.5mm. Check with your service provider for their specific machine’s value | Kerf is the width of material the laser vaporizes. For parts that need to fit together precisely, you must account for this material loss in your design |

| Minimum Hole Size | Hole diameter should be at least 50-100% of the material thickness (such as for 3mm aluminum, holes should be >1.5mm) | Tiny holes are difficult to cut cleanly because the material can’t be ejected properly. The heat builds up, leading to melted or distorted features |

| Minimum Feature Width | The distance between two cut lines should be at least equal to the material thickness | Thin, fragile features (like a narrow web or strut) can easily overheat, warp, or even break during the cutting process due to thermal stress |

| Add Fillets to Sharp Corners | Add a small radius (such as 0.5mm) to all sharp internal corners | A laser slows down to change direction at a sharp corner, introducing excess heat. A small fillet allows for a smoother, faster machine path, reducing heat buildup and improving part quality. |

| Heat Affected Zone (HAZ) | Be aware of a very small HAZ | A fiber laser creates a minimal HAZ on aluminum, but it can still slightly alter the temper of the material right at the edge. For critical structural applications, this should be considered |

Conclusion

Laser cutting aluminum is both an art and a science. While the material’s unique properties make it challenging, the right combination of equipment, settings, and expertise can produce precision components for virtually any industry. Whether you’re a manufacturer, engineer, or buyer, understanding the nuances of the process ensures high-quality outcomes and cost-effective production. For optimal results, always consult a specialist or partner with a provider who is experienced in aluminum laser cutting. Contact us now for your project!

FAQs

A standard CO2 laser cannot cut aluminum. This is because aluminum’s reflective surface and high thermal conductivity prevent the laser from focusing enough energy to cut the metal. Attempting to do so is ineffective and risks damaging the laser’s optics. A high-power fiber laser is a correct tool for cutting aluminum.

This depends entirely on the laser’s power. A 1.5-3kW laser might be limited to 6-8mm, while a powerful 12kW+ system can cleanly cut aluminum over 25mm (1 inch) thick.

The cost varies widely based on several factors, including material type and thickness, the total length of the cut, the number of piercings (holes), part complexity, and order quantity. Using an online quoting service is the best way to get a precise price for your specific part.

Absolutely yes. This is a common and effective application for even low-power CO2 and diode lasers. The laser ablates (burns away) the colored anodized layer, exposing the bright, raw aluminum underneath. This creates a sharp, high-contrast, and permanent mark.