Fiber laser cutting has revolutionized the world of metal fabrication. By leveraging advanced fiber-optic laser technology, manufacturers can achieve precise, fast, and cost-effective cuts across a wide range of materials. In this guide, we provide detailed information about fiber laser cutting, including its operation, comparison to traditional methods, key parameters, applications, and more.

What is Fiber Laser Cutting?

Fiber laser cutting is a precision thermal process that uses a highly focused fiber laser beam to melt, vaporize, or pierce materials along a programmed path. Unlike CO2 laser cutting, which uses gas to generate light, fiber laser transmits energy through a fiber-optic cable, offering better efficiency, beam quality, and lower maintenance.

A typical fiber laser system includes a laser source, fiber delivery cable, collimator, focusing lens, and CNC controller. The beam is focused to a tiny spot with intense power density, enabling it to cut metals like stainless steel, aluminum, copper, and brass with minimal heat-affected zones (HAZ) and clean edges.

Read more: What is laser cutting? A comprehensive guide

How does the Fiber Laser Cutting Process Work?

Fiber laser cutting involves a series of highly controlled, technologically advanced steps to achieve precision cutting. Here is a detailed explanation of each stage in the process:

Beam Generation

The process begins inside the laser source, typically a fiber laser resonator doped with ytterbium (Yb). The system converts electrical energy into light energy through a process called stimulated emission. Ytterbium ions inside the fiber core amplify the light, which is then emitted as a high-powered laser beam. This stage determines the beam’s wavelength (usually around 1064 nm), which is ideal for cutting metals due to its high absorption rate. This internally generated laser beam travels through fiber-optic cables rather than via mirrors, thereby minimizing loss and allowing compact, robust machine designs. The purity of the optical fiber, diode quality, and power supply stability significantly affect the beam’s consistency.

Beam Delivery & Focusing

Once the system generates the laser beam, it travels through a flexible fiber cable to the cutting head. At this point, collimating lenses align the beam into a straight, parallel path. A high-precision lens then focuses the beam into a tiny spot, often less than 100 microns in diameter. This ultra-fine focal spot is critical for achieving high energy density (up to several megawatts per square centimeter), which ensures the material melts quickly and cleanly. High-end machines may include auto-focusing capabilities to adjust focal distance dynamically based on material thickness.

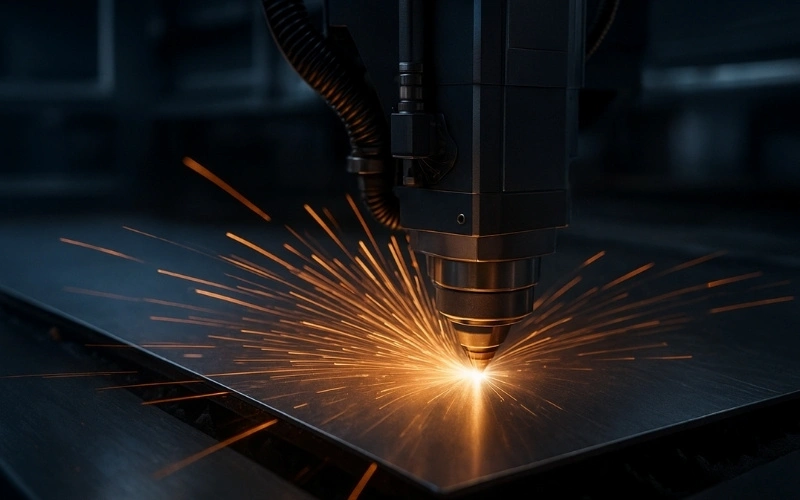

Material Interaction

At the focal point, the intense laser energy interacts with the surface of the workpiece. Depending on the power setting, the material either melts or vaporizes. For most metals like steel or aluminum, the process primarily involves melting. The molten metal is then expelled from the kerf (the narrow cut slot) by a high-pressure assist gas that is delivered coaxially with the beam.

Oxygen is often used for cutting carbon steel, where it also serves as a reactive gas to enhance cutting through exothermic oxidation. Nitrogen is preferred for stainless steel and aluminum to avoid oxidation and achieve cleaner edges. The gas type, pressure, and purity significantly influence the cutting speed, edge smoothness, and the extent of post-processing required.

CNC Motion Control

The motion of the cutting head or the workpiece is controlled using CNC systems. CNC programs, typically generated via CAM software from CAD designs, dictate the exact path, speed, and sequencing of cuts. Linear motors and servo drives ensure micron-level accuracy and repeatability, especially for complex geometries and tight tolerances. Advanced systems also use real-time feedback from encoders and sensors to auto-correct for position deviations, enabling high-precision fabrication even at high speeds.

Real-Time Monitoring and Adaptive Control

Modern fiber laser systems integrate real-time monitoring tools that enhance precision and safety. Sensors detect the success of piercing operations, ensuring the beam has fully penetrated before proceeding with the cut. Height sensors maintain a consistent gap between the nozzle and the material, compensating for any surface irregularities.

Back-reflection sensors protect the laser source from damage caused by reflective materials such as copper and brass. Additionally, some machines are equipped with vision systems and AI-powered software that can identify cutting defects like incomplete kerfs, excessive burrs, or thermal distortion. These systems automatically adjust cutting speed, power, or gas flow on the fly, optimizing both quality and throughput.

What Materials Can Be Cut with Fiber Lasers?

Here are some common materials you can use when applying fiber laser cutting:

- Stainless Steel: For medical devices, food-grade equipment, and architectural features.

- Mild Steel: The workhorse of general fabrication, from machine frames to enclosures.

- Aluminum: Critical for aerospace, automotive, and marine applications where weight is a factor.

- Copper & Brass: Used in electrical components, busbars, and decorative applications.

Read more: What is metal laser cutting and how does it work?

Advantages of Fiber Laser Cutting

Fiber laser cutting has several advantages:

- Blistering speed and efficiency: On thin-to-medium gauge metals, no other technology can match the cutting speed of a fiber laser, resulting in higher throughput and lower cost per part.

- Impeccable precision and quality: The focused beam creates an extremely narrow kerf, allowing for intricate designs, sharp corners, and a smooth edge finish that often requires no secondary processing.

- Versatility with metals: Fiber lasers excel at cutting a wide range of metals, including materials that are highly reflective to other laser types, such as aluminum, copper, and brass.

- Low maintenance and operating costs: The system’s lack of moving parts in the source and the absence of a beam path with mirrors make it incredibly robust. Combined with high electrical efficiency, this leads to the lowest operating cost in the laser world.

- Automation-friendly: The speed and reliability of fiber lasers make them perfect for integration into fully automated production lines with loading/unloading towers and part-sorting systems.

Applications of Fiber Laser Cutting

Fiber laser cutting serves a diverse range of industries, enabling manufacturers and designers to achieve precision, flexibility, and efficiency in production. Below are some common applications:

Automotive

Fiber laser cutting is widely used in the automotive industry for manufacturing intricate and high-precision components. From body panels and battery housings to exhaust systems and structural reinforcements, the ability to cut mild steel, stainless steel, and aluminum with micron-level precision helps manufacturers streamline assembly and reduce vehicle weight. It is especially beneficial for producing electric vehicle (EV) battery trays and brackets where precision and conductivity matter. The process also enables fast prototyping and customized parts for specialized vehicle models.

Aerospace

In aerospace manufacturing, fiber laser cutting is crucial for processing lightweight alloys such as aluminum and titanium. These materials are used in fuselage panels, interior cabin structures, and engine components, where every gram counts for fuel efficiency. The high accuracy and minimal heat-affected zone of fiber lasers prevent material warping, which is vital when working with aerospace-grade materials that must meet strict tolerance and strength requirements. Additionally, fiber lasers assist in fabricating components for drones, satellites, and space exploration equipment.

Electronics

The electronics sector benefits from the fine precision and clean edges achieved by fiber lasers. This technology is ideal for cutting thin metals like copper and stainless steel used in circuit boards, connectors, and shielding enclosures. Fiber laser cutting allows manufacturers to produce compact, densely populated PCBs with narrow traces and precise perforations, ensuring minimal material waste and high throughput. It is also employed in the cutting of metal parts for smartphones, wearable devices, and electronic enclosures requiring intricate cutouts and high dimensional accuracy.

Architecture

In architectural design and construction, fiber laser cutting enables the creation of decorative panels, intricate railings, and detailed façade elements that combine functionality with aesthetics. Stainless steel, corten steel, and aluminum are frequently used for these applications due to their strength and corrosion resistance. Fiber lasers support the fabrication of custom signage, branded elements, and interior accents with sharp edges and consistent quality. Architects and designers value the freedom fiber lasers offer in translating complex digital designs directly into metal structures.

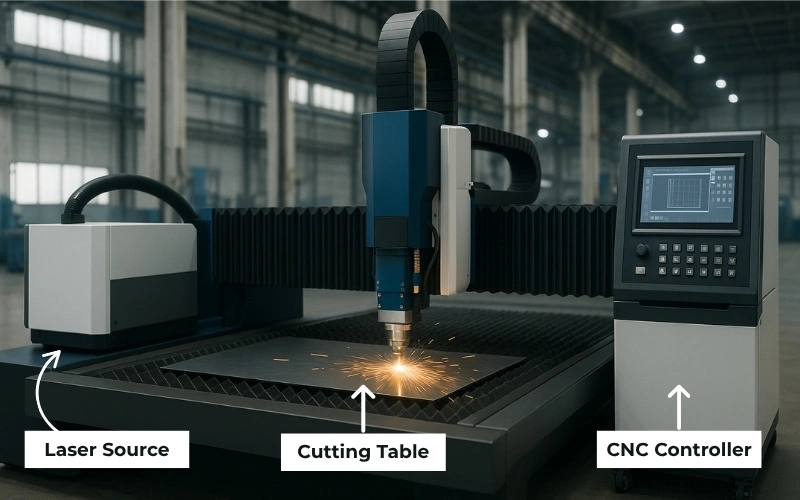

Key Components of a Fiber Laser Machine

A fiber laser cutting machine is a sophisticated integration of optical, mechanical, and electronic systems. Understanding its main parts helps demystify the technology.

Laser Source (Resonator)

This is the heart of the entire machine. A sealed, climate-controlled cabinet protects the resonator, which holds the pump diodes and doped fiber optic spools that generate and amplify the laser beam. The output from this source determines the machine’s power level (such as 2kW, 6kW, or 12kW). Modern sources deliver high reliability and often operate for over 100,000 hours.

Fiber Optic Delivery Cable

This armored, flexible cable is the machine’s circulatory system. It safely transports the powerful laser beam from the source to the cutting head with virtually zero power loss, bending and flexing as the cutting head moves across the gantry.

Cutting Head

This is where the action happens. The cutting head is a high-tech component that receives the laser from the fiber cable and contains the crucial focusing lens assembly. It also houses the channels for the assist gas and features sensors for maintaining a precise distance from the material surface (capacitive height sensing).

CNC Controller

The brain of the operation. The CNC (Computer Numerical Control) is a specialized industrial computer that reads a digital design file (like a DXF or DWG) and translates it into precise motion commands. It controls the cutting head’s X, Y, and Z-axis movements, and also dictates laser power, gas pressure, and cutting speed for the entire job.

Motion System (Gantry)

This is the skeleton and muscles. The motion system is the robust mechanical frame (often a bridge-style gantry) on which the cutting head is mounted. It uses high-precision servo motors, linear guides, and rack-and-pinion systems to move the cutting head over the workpiece at high speeds and accelerations with extreme accuracy and repeatability.

Cutting Table (Bed)

The workbench of the machine. This is a sturdy, slatted or grid-like bed that supports the sheet metal during cutting. The design allows excess material, slag, and the laser beam itself to pass through safely into a collection area below. Many tables integrate with a shuttle system, enabling operators to swap out a finished sheet for a new one while the machine keeps cutting, which maximizes uptime.

Assist Gas System

The lungs of the machine. This system consists of the gas supply (tanks or generators), regulators, and solenoid valves that control the flow and pressure of the assist gas to the cutting head. The choice and control of this gas are critical to the final cut quality.

Chiller

The machine’s radiator. The laser generation process, especially the pump diodes, produces a significant amount of heat. The chiller is an industrial refrigeration unit that circulates coolant to the laser source, keeping it at a stable operating temperature to ensure consistent performance and a long lifespan.

Key Parameters for Optimal Fiber Laser Cutting

Owning a fiber laser is only half the battle; knowing how to tune it is what separates amateurs from professionals. The quality of a finished part is a direct result of a fine-tuned balance between several key parameters. A machine is only as smart as its operator. The table below breaks down the most critical variables and their impact on the final product.

| Parameter | Description | Impact on cut quality |

| Laser Power (W/kW) | The raw energy output of the laser source. | Higher power is required to cut thicker materials. It also allows for faster cutting speeds on thinner materials. Using excessive power can lead to a wider kerf and wasted energy. |

| Cutting Speed (mm/min) | The velocity at which the cutting head moves across the material. | The gas is used to eject molten material. The main types are Nitrogen (N2), Oxygen (O2), and compressed Air. |

| Assist Gas Type | The gas used to eject molten material. The main types are Nitrogen (N2), Oxygen (O2), and compressed Air. | Nitrogen is an inert gas used for “clean cutting” stainless steel and aluminum, providing a shiny, oxide-free edge for welding. Oxygen, a reactive gas, creates an exothermic reaction in carbon steel for faster cutting but leaves a thin black oxide layer. Air is a low-cost compromise, suitable for general-purpose cutting of various materials where edge quality is less critical. |

| Gas Pressure (Bar/PSI) | The force of the gas jet exiting the nozzle. | Pressure must be high enough to cleanly and completely eject the molten material from the kerf. Insufficient pressure leads to dross. Excessive pressure can be wasteful and can cause turbulence, potentially destabilizing the cut on thin materials. |

| Focus Position (Z-axis) | The vertical position of the beam’s narrowest point (focal point) relative to the top surface of the material. | This is one of the most crucial and nuanced parameters. The focus can be set above the surface, on the surface, or below the surface. Its position affects the kerf width, edge straightness, and dross formation. The ideal focus position changes for every different material and thickness. |

Read more: 7 Most Common Fiber Laser Cutting Problems and Solutions

Essential Protocols for Fiber Laser Operation

This section is really important. A fiber laser is a Class 4 laser, the most dangerous class, and safety is non-negotiable. The concentrated beam can cause severe, instant, and permanent injury.

- Eye safety: The 1-micron wavelength of a fiber laser remains invisible to the human eye and passes through the cornea and lens, focusing directly onto the retina. A direct or even a reflected glance can cause permanent blindness instantly. Everyone near an operating machine must wear certified laser safety glasses that match the laser’s specific wavelength. Standard safety glasses offer zero protection.

- Fume extraction: The process of vaporizing metal creates a plume of hazardous fumes and microscopic particles. Inhaling these can cause severe long-term respiratory illness. A powerful and properly filtered fume extraction and ventilation system is not optional; it is an essential part of a safe installation.

- Fire hazards: The intense heat can ignite flammable materials. Keep the work area clear of all combustible items, and place the appropriate class of fire extinguisher (typically Class D for combustible metals) within easy reach.

- Electrical and Mechanical dangers: These are powerful industrial machines with high-voltage cabinets and fast-moving mechanical parts that can cause crushing or fatal injuries. All safety interlocks on machine enclosures must be functional and never bypassed. Only trained and authorized personnel should perform maintenance.

Conclusion

Fiber laser cutting is setting new standards in precision fabrication. With unmatched speed, accuracy, and material versatility, it is the go-to solution across industries. Whether you’re looking to invest in a machine or outsource services, understanding the core principles helps you make smarter decisions.

FAQs

This depends entirely on the laser power. A 1kW laser might effectively cut up to 10mm of mild steel, while a 20kW laser can cleanly cut 50mm of stainless steel or thicker.

Modern fiber laser resonators are incredibly reliable, with most manufacturers rating them for 100,000+ operating hours. This translates to decades of use in a typical single-shift operation.

Definitely yes. By reducing the power and increasing the speed, a fiber laser can be used for surface marking or engraving on metals, often called annealing or etching.