CO2 laser cutting is one of the most widely used technologies in the manufacturing, signage, and crafting industries. Renowned for its precision and ability to work with a broad range of non-metallic materials, this method has become a go-to solution for both industrial professionals and hobbyists. In this article, you’ll learn what CO2 laser cutting is, how it works, the types of materials it can cut, its benefits and limitations, and how to decide if it’s the right choice for your needs. Whether you’re an engineer, entrepreneur, or creative maker, this guide offers everything you need to make informed decisions.

What is CO2 Laser Cutting?

CO2 laser cutting is a thermal laser process that uses a carbon dioxide gas laser to cut, engrave, or etch non-metallic materials like wood, acrylic, and plastics. The CO2 gas, when electrically excited, emits a powerful infrared beam (wavelength 10.6 µm) that can melt, burn, or vaporize surfaces with high precision and low heat distortion.

It excels in handling organic and non-conductive materials, making it ideal for signage, modeling, and packaging. Compared to fiber laser cutting, CO2 systems perform better on thicker, non-metal materials, though they require more maintenance. Their ability to deliver clean cuts and fine detail makes them a top choice in many industries.

Read more: What is laser cutting? A comprehensive guide

How does CO2 Laser Cutting Work?

The process of CO2 laser cutting has four main key stages, including:

Laser Generation

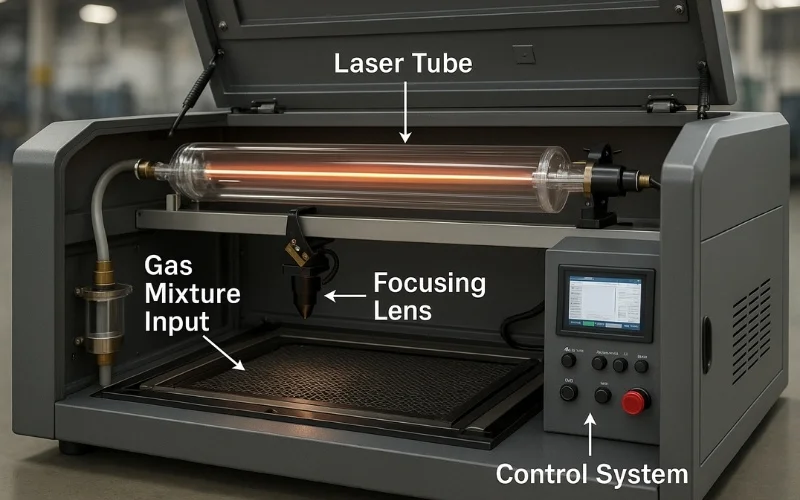

At the core of every CO2 laser machine is a sealed glass or metal laser tube containing a mixture of carbon dioxide (CO2), nitrogen (N₂), and helium (He). When an electrical current or radio frequency (RF) excitation is applied to the gas, it stimulates nitrogen molecules. These molecules then transfer energy to the CO2 molecules, causing them to reach a higher energy state.

When the CO2 molecules return to a lower energy state, they emit photons (particles of light) in the infrared spectrum (wavelength ~10.6 µm). This light emission is amplified within the tube using mirrors at each end. One mirror is fully reflective, and the other is partially reflective to allow a focused beam to escape. The result is a powerful, coherent laser beam.

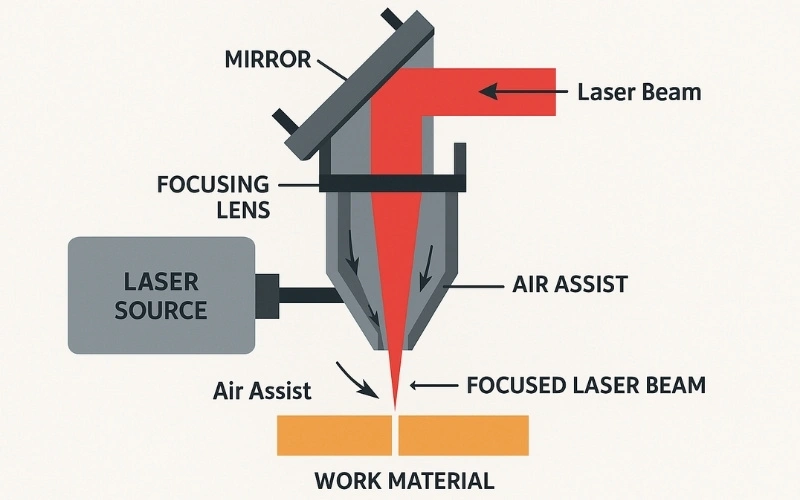

Beam Delivery and Focusing

Once generated, the raw laser beam is guided through a series of highly reflective mirrors, strategically positioned inside the laser head assembly. These mirrors steer the beam through the mechanical path and down into the focusing lens, usually made of zinc selenide (ZnSe).

This lens concentrates the beam to a focal point, a small spot typically less than 0.1 mm in diameter. The energy is intensely focused at this point, creating a heat concentration capable of melting, burning, or vaporizing the target material in microseconds. The focal length of the lens (commonly 1.5″ to 4″) plays a critical role in determining the cutting depth and edge sharpness.

Material Interaction

When the focused beam hits the workpiece, its energy is absorbed by the material. The material’s surface rapidly heats up to the melting or vaporization point. Depending on the laser’s power (typically between 40W to 150W for CO2 systems), and the material type and thickness, three different thermal interactions may occur:

- Melting: Common in metals; the material melts and is expelled from the kerf with assist gas.

- Combustion/Burning: Organic materials like wood or leather oxidize and burn away cleanly.

- Vaporization: Especially for thin plastics or paper, the material changes from solid directly to gas.

The laser beam moves along a pre-programmed path (usually a vector file), tracing precise geometries or intricate engraving details. The movement is managed by a CNC motion controller, ensuring high-precision positioning.

Assist Gas Delivery

As the focused beam makes contact with the material, its intense energy raises the temperature of a tiny spot to its melting or vaporization point almost instantly. The control system moves the cutting head along the path defined by your digital design, creating a continuous cut, or “kerf.” Simultaneously, a jet of compressed gas, known as an “assist gas,” is directed through a nozzle concentric with the laser beam. This gas serves two vital purposes:

- Debris Removal: It blows away the molten or vaporized material from the cut, preventing it from re-solidifying and ensuring a clean, slag-free edge.

- Reaction Assistance (Optional): For some materials, the gas can aid the cutting process. Using compressed air is common for wood and acrylic. Using oxygen with mild steel creates an exothermic reaction that helps cut the material faster. Nitrogen is used to prevent oxidation and discoloration on certain materials.

Key Components of a CO2 Laser Cutter

Understanding the parts of a CO2 laser cutter is like knowing the engine of your car, which helps you troubleshoot and optimize. Here’s a breakdown:

| Component | Function | Maintenance tip |

| Laser tube | Generates the beam by exciting CO2 gas with electricity | Clean optics monthly; replace every 1-2 years for optimal power (from our tests, this boosts efficiency by 15%) |

| Mirrors | Direct and amplify the beam path. | Align precisely; misalignment can reduce cut quality by 20% |

| Focusing lens | Concentrates the beam to a fine point for cutting | Use anti-reflective coatings; clean with isopropyl alcohol to avoid scratches |

| Gas mixture (CO2, N2, He) | Provides the medium for laser generation | Monitor purity; impurities can drop output by 10-30% |

| Control system | Manages power, speed, and design input via software | Update firmware regularly for safety and precision |

What Materials Can and Cannot Be Cut?

The incredible versatility of CO2 lasers comes from the wide range of materials they can process. The 10,600nm wavelength is highly absorbed by organic materials, making it the perfect tool for many applications.

Ideal Materials for CO2 Lasers

The table below provides a quick reference for the most common materials and how they behave under a CO2 laser.

| Material | Excellent for cutting | Note and common use |

| Wood/Plywood/MDF | Yes (flame-polished edge) | Leaves a clean, dark-brown edge. Perfect for signs, models, marquetry, and decorative items. |

| Acrylic (Plexiglass) | Yes | Cuts beautifully, leaving a smooth, “flame-polished” edge. Ideal for signs, displays, awards, and jigs. |

| Leather | Yes | Cuts with high detail. Used in fashion for custom goods like wallets, belts, and patches. Requires good ventilation. |

| Fabric/Textiles | Yes (seals edges) | Cuts synthetic fabrics like felt, denim, and fleece without fraying by melting the edge. Great for cutting patterns. |

| Paper/Cardstock | Yes | Capable of incredibly intricate cuts for invitations, stencils, and papercraft. |

| Delrin (POM) | Yes | An industrial plastic that cuts cleanly. Used for making custom gears, jigs, and mechanical parts. |

| Rubber (Laser-safe) | Yes | Used to create custom rubber stamps and gaskets. Must be laser-safe rubber to avoid toxic fumes. |

Read more: What is Metal Laser Cutting and How Does It Work?

Materials to Avoid

Using the wrong material in a laser cutter is not just bad for your project; it can be catastrophic for your machine and, more importantly, your health. Do not attempt to cut these materials with a CO2 laser under any circumstances.

- Polyvinyl Chloride (PVC): This includes vinyl, Sintra, and other PVC-based products. When heated, it releases highly toxic and corrosive chlorine gas. This gas can cause immediate and severe respiratory damage and will permanently corrode the metal components of your laser cutter.

- Polycarbonate (Lexan): While very strong, polycarbonate absorbs infrared radiation poorly. It tends to melt and catch fire rather than vaporize, leaving a disgusting, sooty edge. It is a major fire hazard in a laser.

- ABS Plastic: This material melts and creates a gooey mess. It also releases cyanide gas when burned, which is extremely poisonous.

- Coated Carbon Fiber: Cutting carbon fiber releases dust and fumes that are harmful to inhale. The epoxy resin can also be problematic.

- HDPE (Milk Jug Plastic): Tends to melt and catch fire easily. It does not cut cleanly.

- Bare Metals: A CO2 laser beam is almost entirely reflected by metals like steel, aluminum, brass, and copper, making it ineffective and dangerous, as the reflected beam can damage the machine or harm the operator.

What are The Advantages and Disadvantages of CO2 Laser Cutting?

No technology is perfect for every application. A balanced view of a CO2 laser’s strengths and weaknesses is essential for making a smart investment.

Advantages

CO2 laser cutting stands out for a few key reasons:

- Unmatched Versatility: It’s the king of non-metals. The ability to cut, mark, and engrave a vast array of organic materials with a single machine is its greatest strength.

- Cost-Effectiveness: For its capabilities, CO2 laser technology is relatively affordable. The upfront cost for a machine is generally lower than a comparable fiber laser.

- High-Quality Finish and Precision: The non-contact cutting process exerts no physical stress on the material, allowing for incredibly intricate and delicate designs. It produces a smooth, often sealed edge on many materials.

- Speed and Repeatability: Once a design is programmed, a laser can reproduce it thousands of times with perfect accuracy, making it ideal for production runs.

Disadvantages

Despite its benefits, CO2 laser cutting also has some limitations:

- Limited on Metals: Poor for reflective surfaces like copper; energy reflects, risking damage.

- High Energy Use: Consumes 10-20kWh per hour, higher than diode lasers.

- Maintenance Needs: Tubes degrade over time, costing $500+ to replace.

- Fume Production: Requires ventilation for toxic emissions from plastics.

Read more: 10 Common CO2 Laser Cutting Problems and How to Fix Them

Essential Safety and Operational Best Practices

A CO2 laser is a powerful industrial tool, not a toy. Its operation demands respect and adherence to strict safety protocols. This is a non-negotiable aspect of ownership and operation.

- Laser Radiation: All CO2 cutting lasers are Class 4 Lasers, the highest and most dangerous classification. The invisible beam can cause instant and permanent eye damage and severe skin burns. Never operate the machine with the safety enclosure doors open, and ensure all safety interlocks are functioning. Always wear certified safety glasses rated for the correct wavelength (OD 5+ at 10,600nm).

- Fire Safety: You are using an intense heat source to burn material. The risk of fire is always present, especially with materials like acrylic and wood. Never leave the machine unattended while a job is running. Keep a CO2-type fire extinguisher within easy reach of the machine at all times.

- Ventilation and Fume Extraction: The smoke produced during cutting is not just unpleasant; it contains harmful particulates and toxic compounds (like acrolein from wood or benzene from acrylic). A powerful fume extraction system that vents to the outside is mandatory for operator health and safety.

- High-Voltage and Mechanical Safety: The machine contains high-voltage power supplies and fast-moving mechanical parts. Never bypass electrical safety features, and keep hands and loose clothing clear of the gantry system during operation.

Conclusion

CO2 laser cutting is a versatile and precise technology that opens up endless possibilities, from product design and prototyping to full-scale production. Whether you’re launching a small business or upgrading your manufacturing process, a CO2 laser could be the tool that transforms your workflow. By understanding how the technology works, what it excels at, and where it falls short, you’ll be better equipped to make the right investment and tap into its full potential.

FAQs

The main recurring tasks are cleaning the mirrors and the focus lens (daily or weekly), checking mirror alignment, cleaning the machine of debris, and maintaining the water chiller. The most significant long-term maintenance is the eventual replacement of the laser tube.

Yes, but it’s limited. It cannot cut reflective metals like aluminum, brass, or copper. With high power (150W+) and an oxygen-assist gas setup, it can cut very thin (under 1.5mm) mild or carbon steel, but the quality is poor and the process is inefficient. A fiber laser is a correct tool for cutting metal.

You typically need two types of software. First, a design program like Adobe Illustrator, CorelDRAW, Inkscape (free), or a CAD program like AutoCAD or Fusion 360 to create your vector files. Second, you need control software like LightBurn (highly recommended), RDWorks, or LaserGRBL to send the design to the laser and control its settings.