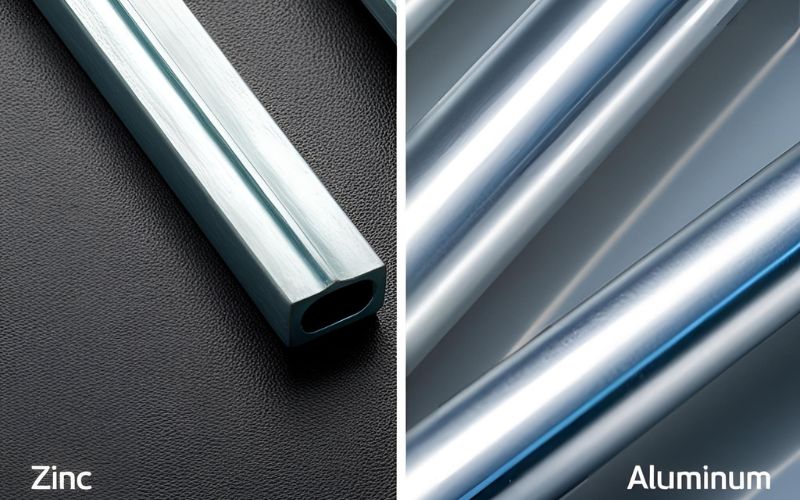

An important question, when choosing between Zinc die casting vs Aluminum die casting, manufacturers consider factors like strength, weight, cost, corrosion resistance, and production efficiency. These two materials dominate die-casting applications in industries such as automotive, aerospace, consumer electronics, and industrial machinery. Selecting the right material can impact product performance, production costs, and durability. This article provides a detailed comparison of zinc and aluminum die casting to help engineers, designers, and procurement managers make an informed decision.

Key Differences: Zinc vs. Aluminum Die Casting

The following table summarizes the key differences between zinc and aluminum die casting:

| Zinc Die Casting | Aluminum Die Casting | |

| Melting Point | Lower (about 380-420°C / 716-788°F) | Higher (about 580-660°C / 1076-1220°F) |

| Density/Weight | Higher (about 6.6-6.7 g/cm³) | Lower (about 2.7 g/cm³) |

| Tensile Strength | Typically 240-350 MP | Typically 300-450 MPa, depending on alloy |

| Hardness | Lower (usually 80-91 HRB) | Higher (usually 60-150 HRB, depending on alloy and heat treatment) |

| Corrosion Resistance | Good (forms a protective patina) | Excellent (forms a natural oxide layer) |

| Tooling Life | Longer (lower melting point and less abrasive) | Shorter (higher melting point and more abrasive) |

| Surface Finish | Excellent (can achieve very smooth, intricate details) | Good (can achieve good surface finishes, but may require more finishing operations) |

| Applications | Small, intricate parts, decorative hardware, automotive components (interior trim), electrical connectors, housings for electronics | Automotive engine blocks, housings, structural components, heat sinks, aerospace parts, marine hardware |

| Cost (Material) | Generally lower per pound (but fluctuates) | Generally higher per pound (but fluctuates) |

| Casting (Process) | Typically Hot-Chamber | Typically Cold-Chamber |

Material Properties Comparison

Let’s delve deeper into the specific material properties:

Metal Injection

Zinc’s significantly lower melting point has several advantages. It allows for faster cycle times in the die-casting process, reducing production time and energy consumption. The lower temperature also puts less stress on the tooling, extending its lifespan.

Density/Weight

Aluminum’s lower density is a major advantage in applications where weight is critical, such as in the automotive and aerospace industries. Lighter parts reduce fuel consumption and improve overall efficiency.

Strength and Hardness

While aluminum generally boasts higher tensile and yield strength, specific zinc alloys (like Zamak alloys) can offer surprisingly good strength for their weight. Hardness, which relates to a material’s resistance to indentation and wear, is generally higher in aluminum alloys, particularly those that have been heat-treated.

Corrosion Resistance

Both zinc and aluminum exhibit good corrosion resistance due to the formation of protective surface layers. Zinc forms a patina, while aluminum forms a thin, tough oxide layer. Aluminum is generally considered superior in harsh environments, especially saltwater exposure. However, various surface treatments like plating, painting, or anodizing can further protect both materials.

Thermal and Electrical Conductivity

Aluminum is a significantly better conductor of both heat and electricity than zinc. This makes it the preferred choice for applications like heat sinks and electrical enclosures where efficient heat dissipation or electrical conductivity is essential.

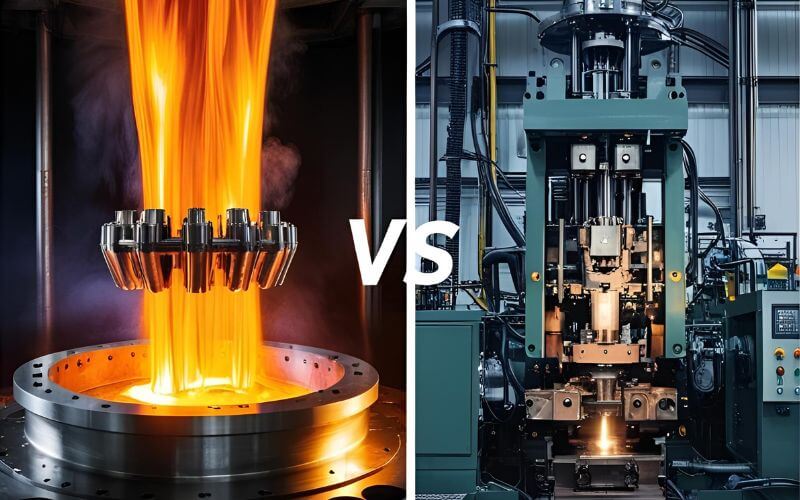

Types of Die Casting Methods

The die casting process itself differs slightly depending on the material:

- Hot Chamber vs. Cold Chamber: Due to its lower melting point and lower reactivity with steel, zinc is typically processed using the hot-chamber die casting method. In this process, the injection mechanism is submerged in the molten metal, allowing for faster cycle times. Aluminum, with its higher melting point and greater tendency to react with steel at high temperatures, is usually processed using the cold-chamber method. Here, the molten metal is ladled into a separate chamber before being injected into the die.

- Tooling Considerations: The lower temperatures and less abrasive nature of zinc lead to significantly longer tooling life compared to aluminum. This can result in substantial cost savings over the long term, especially for high-volume production runs.

- Cycle Time: As mentioned earlier, zinc’s lower melting point and the use of the hot-chamber process typically result in faster cycle times compared to aluminum.

- Finishing Operations: Zinc is often preferred for high-quality surface finishes because it is easier to cast with intricate details.

Cost Comparison between Zinc vs Aluminum Die Casting

The cost of die casting with zinc versus aluminum is a complex equation involving several factors:

- Material Cost: The raw material cost per pound can fluctuate, but zinc is often (though not always) less expensive than aluminum.

- Tooling Cost: Zinc tooling generally lasts much longer, leading to lower tooling costs over the life of a project.

- Production Cost: Faster cycle times for zinc can translate to lower production costs per part.

- Finishing Cost: Zinc often requires less finishing, which can reduce costs.

- Total Cost of Ownership: It’s crucial to consider the total cost, including all the factors above, rather than just the initial material cost.

How to Choose Between Zinc vs Aluminum Die Casting?

Selecting the right material requires careful consideration of your project’s specific requirements:

- Required Strength and Durability: If high strength and durability are paramount, aluminum alloys are generally the better choice. However, for many applications, zinc alloys offer sufficient strength.

- Weight Requirements: If minimizing weight is critical, aluminum is the clear winner due to its lower density.

- Corrosion Resistance Needs: Aluminum generally offers superior corrosion resistance in harsh environments, especially saltwater exposure. However, zinc with appropriate surface treatments can perform well in many environments.

- Dimensional Accuracy and Complexity: Zinc is often preferred for intricate parts with tight tolerances due to its lower melting point and excellent castability.

- Production Volume: For very high-volume production runs, the longer tooling life of zinc can lead to significant cost savings.

- Budget Constraints: While material costs fluctuate, zinc is often (but not always) less expensive per pound. Consider the total cost of ownership, including tooling, production, and finishing.

- Desired Surface Finish: If a superior, smooth surface finish is required with minimal post-processing, zinc is often the better choice.

Conclusion

The choice between zinc and aluminum die casting ultimately depends on the specific requirements of your application. Zinc excels in applications requiring intricate details, excellent surface finish, and longer tooling life, while aluminum is preferred for applications demanding high strength, lightweight, and superior corrosion resistance in harsh environments. Consulting with a die-casting expert is highly recommended to determine the optimal material for your project. We can help you analyze your needs and provide a customized solution. Contact us today for more information!