TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is often considered the peak of precision welding. Unlike other faster but less controlled methods, TIG offers unmatched accuracy, producing clean, durable, and visually flawless welds on everything from stainless steel exhausts to aerospace titanium parts. But how exactly does it work, and why is it the go-to choice for industries that demand perfection? In this guide, we’ll uncover the process, equipment, common metals, and mistakes you should avoid to truly understand TIG welding.

What is TIG Welding?

TIG welding is a precise welding process that uses a non-consumable tungsten electrode and shielding gas such as argon or helium to protect the molten weld pool. Unlike stick welding, filler can be added separately for stronger weld beads and deeper penetration. Valued for its heat control on thin metals like aluminum and stainless steel, it’s common in aerospace, automotive, and precision engineering, but requires high skill, proper AC/DC polarity, and controlled gas flow to prevent welding defects.

Read more: What is MIG Welding? How to MIG Weld Thin Metal

How Does TIG Welding Work?

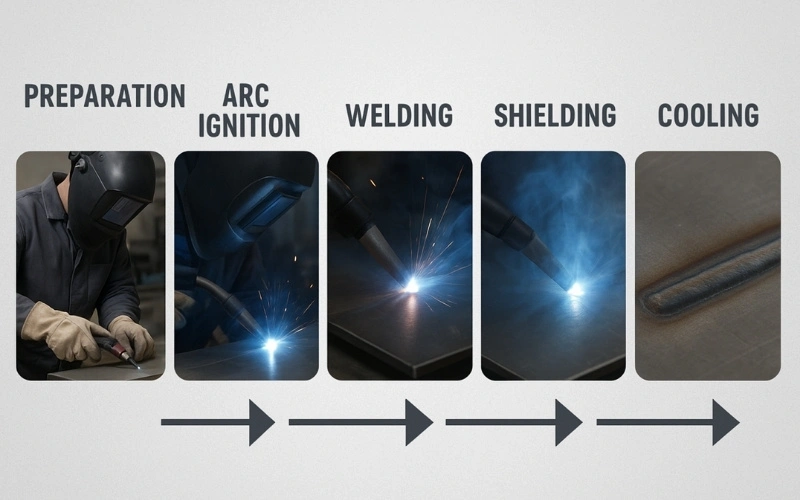

The TIG welding process may look complex at first, but it can be broken down into a series of clear, repeatable steps. By following these stages, from preparation to cooling, you can achieve clean, strong, and consistent results.

Preparation

TIG welding succeeds or fails in the preparation stage. Clean, fit, and set up everything before you strike an arc so you don’t chase preventable defects mid-weld.

- Clean metals: remove oil, paint, rust, and oxides (use solvent, stainless brush for aluminum).

- Fit-up: check gap, root alignment, tack-weld if needed for consistency.

- Select consumables: choose tungsten type/diameter, filler rod alloy, and nozzle size.

- Set machine: choose AC/DC polarity, set amps to material thickness, and adjust pulse if used.

- PPE & workspace: helmet, gloves, ventilation, and eliminate drafts around the weld zone.

Arc ignition

Start reliably and without contaminating the tungsten. Use the correct start method for the job and keep the arc stable.

- Choose start method: high-frequency (clean, non-contact) or lift/scratch start (simple, reliable).

- Position tungsten: point ~1-2 mm from the workpiece before triggering HF or lift.

- Avoid contact: don’t let tungsten dip into the molten pool — if touched, stop and re-grind.

- Safety check: ensure gas flow is active before ignition to protect tungsten and metal.

Welding

Next is welding. This is where control matters: create a steady pool, add filler correctly, and maintain consistent motion.

- Establish puddles: form a uniform molten pool before adding filler.

- Torch angle & distance: hold torch ~10-15° off vertical, keep arc length short (≈1-2 mm).

- Filler technique: feed filler into the leading edge of the puddle (not into the arc).

- Travel speed & rhythm: steady speed for even bead width and penetration; use the foot pedal to modulate heat.

- Watch for signs: discoloration, excessive smoke, or erratic arc means adjust settings or prep.

Shielding

Shielding gas is the invisible guard – inadequate coverage causes porosity and contamination.

- Gas choice: argon for most jobs; add helium for deeper penetration on thick sections.

- Flow rate: typically 10-20 CFH (adjust for cup size and wind).

- Nozzle & lens: use a proper cup size and consider a gas lens for improved laminar flow.

- Protect from drafts: close doors, shield the area – even small air currents ruin the weld.

Cooling

The final step in this process is cooling. Controlled cooling preserves weld integrity and reduces cracking or distortion.

- Post-flow gas: keep gas flowing for a few seconds after stopping the arc to protect the hot weld metal.

- Slow cooling for some alloys: preheat or use interpass temperature control for thick or crack-prone metals.

- Avoid rapid quenching: do not immediately douse hot parts; let them cool naturally or with controlled measures.

- Inspect & clean: once cool, remove any surface oxides, check for defects, and document interpass temps if required.

Common Metals Used in TIG Welding

TIG’s versatility is one of its greatest assets. It can produce high-quality welds on:

- Aluminum (ER4043 or ER5356): Use AC with adjustable balance/frequency; meticulous surface prep for oxide removal.

- Carbon/mild steel (ER70S‑2 filler): Clean, controllable beads; avoid overheating to limit distortion.

- Stainless steel (ER308L/ER316L): Maintain short arc, use gas lens, and manage heat tint; back‑purge for full‑penetration joints to prevent “sugaring.”

- Magnesium: Similar to aluminum, it demands clean work and AC.

- Nickel alloy (like Inconel): Stable DC arc; often requires precise heat input and purge.

- Titanium: Exceptional sensitivity to oxygen; requires trailing shields and extended post‑flow. Color is an immediate quality indicator.

Read more: Top 5 methods to master welding sheet metal

Aluminum TIG Welding Specifics

Welding aluminum presents a unique challenge that TIG is perfectly suited to solve. Aluminum is always covered by a tough, transparent layer of aluminum oxide, which has a much higher melting point (~3700°F) than the aluminum underneath (~1220°F).

To weld it, you must first break through this oxide layer. This is accomplished by using Alternating Current (AC) on the TIG machine.

- The AC cycle rapidly switches the electrical polarity. During the Electrode Positive (EP) phase of the cycle, the current flows from the workpiece to the tungsten, blasting away the oxide layer in a process called “cleaning action.”

- During the Electrode Negative (EN) phase, the current flows from the tungsten to the workpiece, providing the heat and penetration needed to melt the aluminum and form the weld.

- Modern TIG welders allow you to fine-tune this AC balance to control the amount of cleaning vs penetration for optimal results.

TIG Welding Equipment

To achieve quality results, TIG welding requires more than just skill. It also depends on the right equipment working together. From the welding machine to the electrodes and shielding gases, each component plays a critical role in ensuring precision and reliability.

TIG Welder (Power Source)

At the heart of every TIG setup is the power source, which provides the stable current necessary to create and control the welding arc. Unlike simple welding machines, TIG welders often feature AC/DC capability, allowing welders to adapt to different metals and applications.

- Direct Current Electrode Negative (DCEN): Commonly used for steels, stainless steel, copper, and titanium because it provides deep penetration with a stable arc.

- Alternating Current (AC): Essential for aluminum and magnesium, as it helps break through the oxide layer while maintaining strong fusion.

- Amperage Control: Many TIG machines include foot pedals or fingertip controls to adjust heat on the fly, offering precision unmatched by other welding processes.

- Advanced Features: Some modern power sources offer pulsed TIG modes, memory settings, and digital displays for greater accuracy and repeatability.

TIG Torch

The TIG torch is a precision tool with several consumable parts that must be correctly sized for the tungsten electrode being used:

- Torch Body: The main handle, which connects to the welding cables and gas hose. They can be air-cooled for lower amperage work or water-cooled for heavy-duty industrial applications.

- Collet and Collet Body: These are small, slotted copper pieces inside the torch head that grip the tungsten electrode when the back cap is tightened.

- Nozzle: A ceramic or glass cup that threads onto the front of the torch. It directs the flow of shielding gas over the weld area. They come in various sizes for different applications.

- Back Cap: The cap that screws onto the back of the torch head. It holds the internal components in place and provides a seal for the shielding gas.

Tungsten Electrodes

Tungsten electrodes are color-coded to identify their alloy composition. The right choice depends on the material being welded and the type of power source.

| Tungsten Type | Color | Primary Use | Characteristics |

| Pure Tungsten (EWP) | Green | AC (Aluminum) | Forms a balled tip, providing good arc stability for AC welding. Not suitable for DC. |

| 2% Thoriated (EWTh-2) | Red | DC (Steel) | The long-time industry standard for DC. Excellent arc starts and high current capacity. Slightly radioactive. |

| 2% Ceriated (EWCe-2) | Orange | DC (All-purpose) | Excellent for low-amperage DC welding. Great arc starts and stability. A good non-radioactive alternative to Thoriated. |

| 2% Lanthanated (EWLa-2) | Blue | AC & DC | The most versatile, all-around electrode. Performs extremely well on both AC and DC, making it a popular choice for modern inverter welders. |

Inert Gases

The “IG” in TIG stands for Inert Gas, which is essential for a successful weld.

- Argon (Ar): This is the most common shielding gas used for TIG welding. It is an excellent all-purpose gas that provides great arc stability and cleaning action on a wide variety of metals, including steel, stainless steel, and aluminum. It is also relatively inexpensive.

- Helium (He) / Argon-Helium Mixes: Helium produces a hotter arc than Argon. Adding helium to an Argon mix (such as a 75% Argon / 25% Helium blend) increases heat input and penetration. This is beneficial for welding thick aluminum or copper, which dissipates heat very quickly.

Read more: MIG vs TIG vs Stick welding: Which method should you use?

Mistakes You Should Avoid

Even skilled welders can run into problems if they overlook the fundamentals. Recognizing the most frequent TIG welding mistakes helps beginners save time, reduce defects, and build good habits from the start.

- Dipping the Tungsten: Accidentally touching the tungsten electrode to the weld pool or filler rod is the most common beginner mistake. This contaminates the tungsten, requiring you to stop, regrind it, and restart.

- Using Too Long an Arc: Holding the torch too far from the workpiece will cause the arc to wander and will result in a wide, weak weld with poor shielding gas coverage. Keep it tight.

- Contaminating the Filler Rod: Do not pull the filler rod completely out of the shielding gas envelope between dips. The hot end of the rod will oxidize if exposed to the air and will then introduce contaminants into your weld pool. Keep it within the gas shield.

- Poor Gas Coverage: Too little gas flow won’t protect the weld; too much will cause turbulence and pull in air. Check for leaks in your lines and ensure your cup size is appropriate for the joint.

Conclusion

TIG welding is widely respected for its precision, versatility, and superior weld quality. While it requires more practice and skill than other methods, the results are unmatched in industries where weld quality cannot be compromised. Whether you’re working on aerospace components, automotive parts, or fine metal art, mastering TIG welding gives you control and confidence at the highest level of the trade.

FAQs

Yes. This is called an “autogenous weld.” It is commonly used to fuse the edges of two pieces of thin sheet metal that fit together perfectly. The base metals are simply melted together to form the joint.

For over 95% of applications, including all steel, stainless steel, and aluminum, the shielding gas used is 100% Argon. In some high-performance or specialized cases, an Argon/Helium blend might be used for increased heat input on thick aluminum or copper.

The cost is due to several factors: the welding machines (especially AC/DC models) are more complex and costly to manufacture; the process is slow, leading to higher labor costs; and it uses a higher volume of shielding gas compared to MIG welding for the same length of weld.