Whether you’re just starting your welding journey or you’ve been laying beads for years, stick welding (or SMAW) remains one of the most versatile and reliable techniques in the trade. From farm repairs to skyscraper construction, it’s valued for its strength, portability, and ability to perform even in tough outdoor conditions. In this guide, you’ll discover everything you need to know: from choosing the right electrodes and settings to mastering weld positions and solving common problems. Clear explanations, practical tips, and safety advice will help you build confidence and skill, whether you’re welding at home or on the job site.

What is Stick Welding?

Stick welding, or Shielded Metal Arc Welding (SMAW), is a manual arc welding process using a flux-coated electrode. An electric arc melts the rod and base metal, forming a weld pool. The flux creates shielding gas and slag, protecting the weld bead from porosity and oxidation. Known for its portability and versatility, it is widely applied in construction, pipelines, and shipbuilding. While reliable outdoors, it produces spatter, requires frequent electrode changes, and is slower than other arc welding techniques.

Read more: Five methods to master welding sheet metal

How is Stick Welding Applied in Real Life?

Stick welding remains one of the most widely used processes worldwide due to its versatility and ability to perform in tough conditions. Below are the main industries and situations where it shines:

Construction and Structural Steel

Stick welding is a go-to method for building bridges, buildings, and heavy steel frameworks. Its deep penetration and strength make it reliable for critical joints.

- Commonly used with E7018 low-hydrogen rods for high-strength applications.

- It can be performed outdoors and in windy environments, unlike MIG welding or TIG welding.

- Ideal for beam connections, columns, and reinforcement structures.

Pipeline and Oil & Gas Industry

SMAW has been a standard in pipeline welding for decades, especially with electrodes such as E6010 and E7010, which allow open-root passes and vertical-up techniques.

- Excellent for welding long-distance pipelines in remote areas.

- Handles thick-walled pipe joints requiring multiple passes.

- Known for producing reliable, full-penetration welds under strict codes.

Shipbuilding and Offshore Welding

Ships, rigs, and offshore structures demand welding that holds up in harsh conditions. Stick welding is chosen for its portability and reliability.

- Works well on large steel plates and heavy components.

- Performs even in windy or damp environments near the sea.

- Critical for repairing hulls, decks, and offshore oil platforms.

Repair and Maintenance Work

From farm equipment to industrial machinery, stick welding is the first choice for repair work because it can be applied almost anywhere.

- Handles rusty, painted, or dirty metal better than most processes.

- Works well on broken machinery, agricultural tools, and heavy equipment.

- Portability makes it easy to bring the welder to the repair site.

Heavy Manufacturing and Industrial Applications

Industries like railroads, mining, and fabrication shops still rely on stick welding for heavy-duty applications.

- Used for joining thick sections of steel where strength is critical.

- Suitable for multi-pass welds on industrial frames and machinery.

- Provides robust, long-lasting welds that meet safety standards.

Hobbyist and DIY Projects

While professionals dominate many of its uses, stick welding is also accessible for hobbyists. Small inverter stick welders are inexpensive and portable.

- Perfect for metal art, small repairs, and DIY fabrication.

- Great way for beginners to learn arc control and bead formation.

- Lower cost of entry compared to MIG/TIG equipment.

Read more: MIG vs TIG vs Stick welding techniques

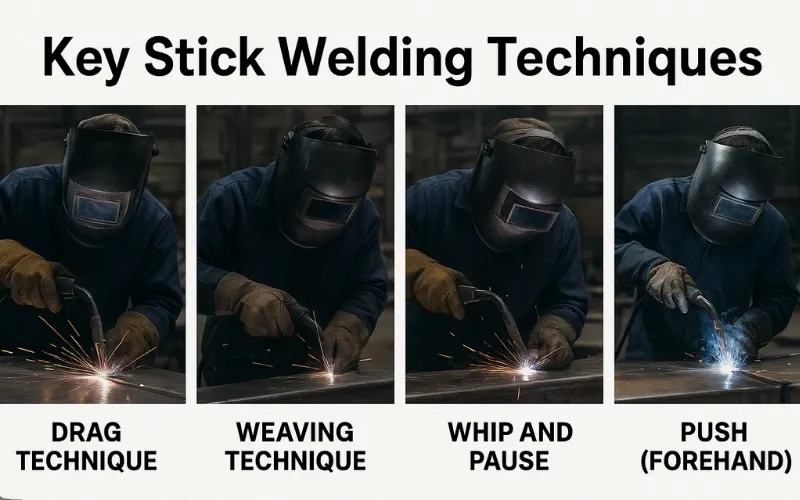

Key Stick Welding Techniques

Stick welding offers different approaches depending on the electrode, metal, and position. By mastering the following techniques, welders can adapt to almost any situation.

Drag (Backhand) Technique

The drag method is the most common approach in stick welding. You hold the electrode at a backward angle (leaning away from the direction of travel) and pull it along the joint. This creates deeper penetration and is particularly effective with low-hydrogen rods like E7018.

- Electrode angle: 10-15° backhand (dragging away).

- Best use: General welding, structural steel, outdoor work.

- Watch out for: Moving too fast, which can cause undercutting.

Push (Forehand) Technique

In contrast to dragging, the push technique angles the electrode forward in the direction of travel. This reduces penetration but creates a smoother, flatter bead. It’s best suited for thin sheet metal or electrodes designed for shallow fusion.

- Electrode angle: 10-15° forward.

- Best use: Thin steel, light fabrication, cosmetic welds.

- Watch out for: Weak weld strength if used on thick metal.

Weaving

Weaving involves moving the electrode side-to-side across the joint. This helps spread out the bead, fill wider gaps, and control heat input. It’s widely used in vertical and overhead welding.

- Motion: Controlled side-to-side sweep (Z, V, or crescent pattern).

Best use: Vertical up welding, wide joints, filling passes. - Watch out for: Excessive weaving (more than 3x rod diameters) can weaken welds.

Stringer Beads

Stringer beads are straight, narrow passes without weaving. They’re perfect for root passes or when multiple passes are required. Professionals often use stringers to ensure consistent penetration and bead profile.

- Motion: Straight line, minimal side movement.

- Best use: Root passes, multi-pass welds, deep penetration.

- Watch out for: Lack of overlap between passes, which may leave slag inclusions.

Whipping or Puddling Motion

This technique is popular with fast-freeze rods like E6010 and E6011. The electrode is moved forward slightly, then whipped back into the puddle, allowing the molten metal to freeze and preventing sagging in vertical positions.

- Motion: Quick forward step, then return to the puddle.

- Best use: Open-root passes, vertical-up welding, pipeline work.

- Watch out for: Inconsistent rhythm, which leads to uneven beads.

Circular Motion

Using small circles or crescent-shaped motions with the electrode can help build up the bead and achieve a smooth, even appearance. This technique also helps control heat when welding thicker materials.

- Motion: Small circles or crescent shapes along the joint.

- Best use: Filling gaps, cosmetic welds, smooth bead finishes.

Watch out for: Circles too large, which can cause overheating and porosity.

Common Challenges and Troubleshooting Tips

Sometimes you will run into problems. It’s a guarantee. Here’s a quick guide to fixing the most common issues.

| Problem | Causes | How to Fix |

| Rod Sticking Constantly | Amperage is too low; you are not pulling back fast enough after striking the arc | Increase amperage by 5-10 amps; practice a quick “tap and lift” motion |

| Porosity (Small Holes/Pits) | Travel speed is too fast for the amperage, holding an incorrect rod angle | Keep a much tighter arc; use fresh, dry electrodes; clean your metal to a bright shine before welding |

| Excessive Spatter | Amperage is too high; arc length is too long; incorrect polarity | Lower your amperage; keep a tight arc length; double-check that your machine is set to DCEP |

| Undercut (Groove Along Weld) | Travel speed is too fast for the amperage; holding an incorrect rod angle | Slow down your travel speed and allow the puddle to fill in the edges; maintain a consistent 10-15 degree drag angle |

Stick Welding Tips for Better Results

Achieving optimal results in stick welding requires patience and practice. Start by ensuring the metal surface is clean. Remove rust, oil, or paint before welding. This helps prevent impurities in the weld. Practice on scrap metal is invaluable. It helps develop a steady hand and confidence.

Consistent practice enhances skill and precision over time. Adjusting settings based on metal thickness is essential. Use the correct current and electrode type. This ensures strong welds and reduces defects. Here are some additional improvement tips:

- Maintain consistent speed: Keep bead uniform.

- Watch electrode angle: Affects penetration.

- Monitor arc length: Too long weakens the arc.

- Check settings regularly: Adjust for different conditions.

Implementing these tips enhances welding quality. Over time, they become second nature, leading to superior results

How to Improve Your Stick Welding Skill?

Improvement in stick welding begins with regular practice. Dedicate time each week to refining your skills. Consistency is key to mastering techniques. Experimentation is also crucial. Test different electrodes and settings. Find what works best for various metals and conditions. Here’s how you can enhance your skills:

- Set Goals: Focus on specific techniques each session.

- Seek Feedback: Have a mentor review your work.

- Document Progress: Keep a log of settings and results.

- Review Mistakes: Learn from what goes wrong.

Through perseverance and dedication, you can significantly enhance your stick welding abilities. Remember, even small improvements lead to better overall quality.

Conclusion

Mastering stick welding skills is invaluable for various projects. It offers versatility in materials and applications. From industrial sites to DIY tasks, its role is crucial. Skilled welding ensures strong, reliable connections. It enhances project outcomes and boosts efficiency. Whether a hobbyist or professional, investing in this technique pays dividends. If you want to find a company that provides high-quality stick welding service, we are the most ideal choice for you. Please feel free to contact us to discuss your project!

FAQs

No. Stick welding does not require an external shielding gas. The electrode’s flux coating decomposes during welding, releasing gases that shield the molten pool from contamination. This makes stick welding ideal for outdoor conditions where wind would blow shielding gas away.

It depends on the application. Stick welding often provides deeper penetration on thick or dirty steel, while MIG offers faster, cleaner welds on thin, clean metal. For heavy-duty outdoor work, stick welding is often the stronger choice.

In most cases, you should pull (drag) the electrode at about a 10-15° angle. Pulling ensures deeper penetration and proper slag coverage. The push technique is less common in stick welding and is usually reserved for thin metals with specific electrodes like E6013.