Stainless steel is prized in industries from architecture and automotive to healthcare for its strength and corrosion resistance. However, these same qualities make it difficult to bend, which often leads to springback, cracking, or surface damage. Whether you’re working in a professional shop or a home garage, understanding how this material behaves, the most effective bending methods, and how to avoid costly mistakes is essential. In this guide, we will cover everything that you need to know, from stainless steel’s unique properties and bending techniques to best practices and practical applications.

What is Stainless Steel Bending?

Bending stainless steel is the process of reshaping sheets, bars, or tubes into angles or curves without cracking. Unlike cutting or welding, it relies on controlled force through a press brake, roller, or manual tools. Stainless steel’s high tensile strength, low ductility, and issues like springback or work hardening make bending harder. Results depend on the grade (such as 304 or 316) and the method used (air bending, bottoming, or coining).

To improve accuracy, fabricators use CNC press brakes with V-dies or radius tooling that minimize cracking and surface damage. Though challenging, bending is vital for durable parts in automotive, construction, food, and medical industries. Success relies on balancing the material’s behavior with proper tooling, force control, and safety practice

Read more: Sheet metal bending: A complete guide

How to Bend Stainless Steel?

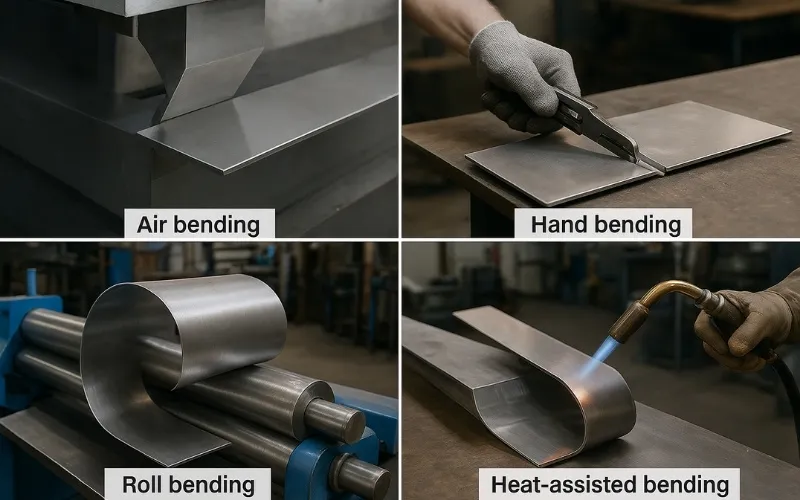

Different methods can be used to bend stainless steel depending on the material’s thickness, grade, and the final application. Each method comes with its own advantages, limitations, and best-use scenarios.

Air Bending

Air bending is the most widely used method in press brake operations. In this process, the punch presses the stainless steel sheet into a V-shaped die without forcing the material to fully conform to the die. The bend angle is determined by the depth of penetration, making the process versatile and efficient.

Pros:

- Versatility: A single set of a punch and V-die can produce a wide range of bend angles simply by adjusting the stroke depth.

- Lower Tonnage: Air bending requires significantly less force than other methods, reducing stress on the machine and tooling.

- Larger Inside Radius: It naturally creates a radius in the bend that is a percentage of the V-die opening, which is often ideal for preventing cracks in stainless steel.

Cons:

- Springback: This method is the most susceptible to stainless steel’s high springback. Achieving a precise angle requires careful calculation and over-bending to compensate.

- Accuracy: The final angle is dependent on material consistency (thickness, grain direction) and the machine’s precision.

Hand Bending (Manual Bending)

Hand-bending is the simplest approach, suitable for thin stainless steel sheets or small projects. This method usually involves a bench vice, hammer, or manual bending brake. While it’s easy to perform, it offers less precision compared to industrial equipment.

- Best for: thin sheets (typically less than 1 mm) or DIY applications.

- Advantages: low-cost, requires minimal equipment, good for quick or small bends.

- Limitations: accuracy is limited, can cause surface scratches if the tools are not smooth, unsuitable for thicker stainless steel.

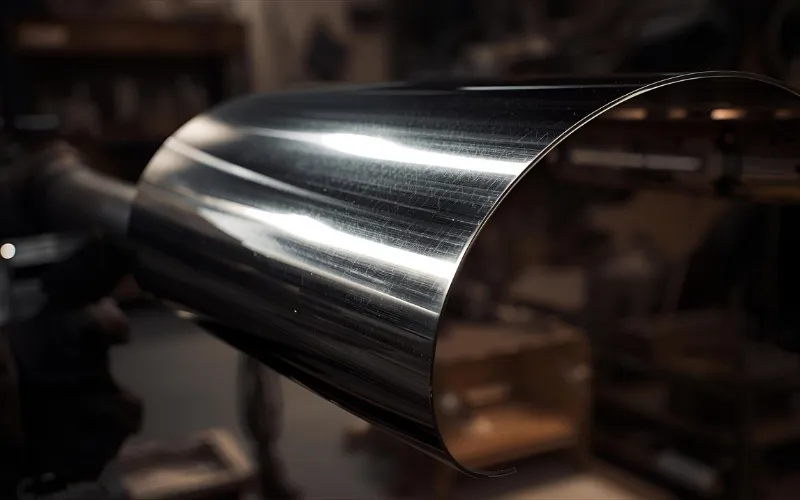

Roll Bending

Roll bending is mainly used to create curves or cylindrical shapes rather than sharp angles. Sheets, tubes, or bars are passed through a set of rollers to gradually form the desired curve. It is appropriate for large-radius curves, pipes, tanks, or architectural components.

Advantages:

- Produces smooth, continuous curves.

- Works for both thin and thick materials.

- Suitable for large-scale components where aesthetics matter.

Limitations:

- Not ideal for sharp bends or small parts.

- Requires large, specialized equipment.

Heat-Assisted Bending

When stainless steel is too thick or rigid to bend cold, applying heat makes the metal more workable. However, heating can alter the material’s properties and appearance, so extra care is needed. It is usually used for heavy-gauge stainless steel plates.

Advantages:

- Reduces the risk of cracking.

- Requires less force than cold bending.

- Enables bending of very thick sections.

Limitations:

- May cause discoloration (heat tint).

- It can reduce corrosion resistance unless the surface is re-treated.

- Needs post-bending finishing, such as passivation or polishing.

What are The Properties of Stainless Steel that Affect Bending?

Before bending stainless steel, it’s critical to understand the material’s unique properties. These characteristics directly affect how easily the metal can be formed and what precautions must be taken.

Tensile Strength and Ductility

Stainless steel is stronger than many other metals, which means it resists deformation. This high tensile strength is what gives stainless steel its durability and toughness in applications. At the same time, ductility (the ability to deform without breaking) varies across grades. Austenitic stainless steels, such as 304, are generally more ductile and easier to bend, while ferritic or martensitic grades tend to be less forgiving. Here are the reasons why it matters for bending:

- High strength = requires more force to bend.

- Good ductility = reduces the risk of cracks or fractures.

- Different grades behave differently (choosing the right one makes the process smoother).

Work Hardening and Springback Effect

When stainless steel is bent, it doesn’t just change shape – it actually becomes stronger through a phenomenon called work hardening. This means the metal resists further deformation, making additional bends harder. Another related factor is springback, where the metal naturally tries to return to its original shape after bending. Both must be compensated for when planning the bend. It matters for bending because:

- Work hardening makes repeat bending or corrections more difficult.

- Springback requires fabricators to overbend slightly to hit the target angle.

- Not accounting for these effects leads to inaccurate results and wasted material.

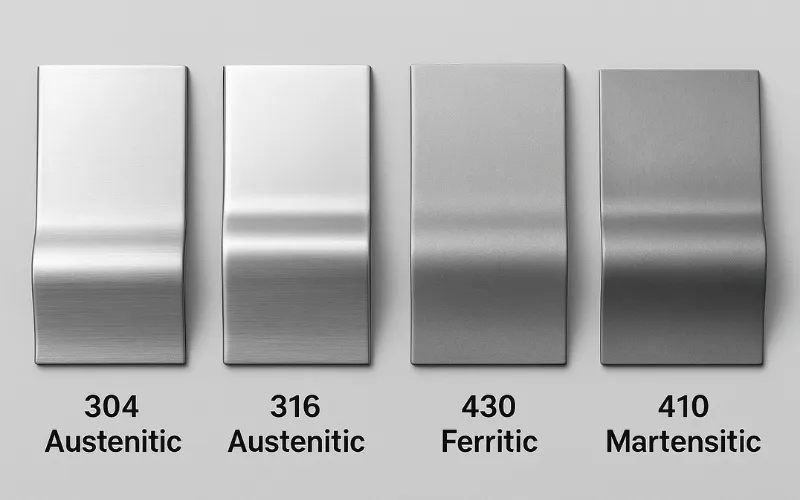

Types of Stainless Steel

Not all stainless steels are equal when it comes to bendability. The composition (especially the balance of chromium, nickel, and carbon) affects hardness and ductility. Austenitic grades like 304 and 316 are most commonly used for bending because they balance strength and flexibility. Ferritic and martensitic grades, however, can crack if bent too sharply.

| Common Applications | Ease of Bending | Notes | |

| 304 Austenitic | Kitchen equipment, railings | Easy | Most commonly used, high ductility |

| 316 Austenitic | Marine, medical equipment | Moderate | Corrosion resistant, slightly tougher |

| 430 Ferritic | Appliances, automotive trim | Difficult | Corrosion-resistant, slightly tougher |

| 410 Martensitic | Tools, knives | Very difficult | Prone to cracking, low ductility |

Common Problems & Professional Solutions

Even with the right knowledge, issues can arise. Here’s how to diagnose and fix the most common stainless steel bending problems.

| Problem | Cause | Solution |

| Cracking on the Outside of the Bend | The inside bend radius is too small for the material thickness. Bending against the material’s natural grain | Increase the punch radius. A larger radius reduces stress. Orient the part so the bend line is parallel to the grain direction of the sheet |

| Scratches on the Part | Direct metal-to-metal contact with the die. Debris or grit on the die surface | Always use a protective polyurethane film over the die. Ensure tooling is clean, polished, and free of defects |

| Inaccurate Bend Angles | Incorrect springback compensation. Inconsistent material properties | Perform a test bend on every new batch of material to confirm the springback value. Use a high-precision method like bottoming if air bending isn’t consistent enough |

| Deformation of the Flange | A large, unsupported sheet is deforming upwards as the bend is completed, causing distortion | Use sheet followers or front supports on the press brake to support the material’s weight during the bend. For very large parts, a second operator may be needed |

Read more: Common sheet metal bending defects and how to fix them

Safety Precautions for Stainless Steel Bending

Working with press brakes is a high-risk activity that demands uncompromising attention to safety.

- Personal Protective Equipment (PPE): Always wear ANSI-rated safety glasses, heavy-duty cut-resistant gloves, and steel-toed boots.

- Machine Guarding: Never operate a press brake with safety guards, light curtains, or two-hand controls disabled. Ensure they are tested and functional at the start of every shift.

- Material Handling: Stainless steel sheets are heavy and have razor-sharp edges. Use proper lifting techniques or mechanical aids to prevent back injuries and cuts.

- Tooling Safety: NEVER place your hands or any body part between the punch and die. Stop the machine completely before making any adjustments.

Conclusion

Bending stainless steel is both challenging and rewarding due to its strength, durability, and corrosion resistance. Achieving high-quality results requires understanding its material properties, selecting the right bending method, accounting for springback, and following best practices. Whether you’re a DIY enthusiast working on a small project or an industry professional managing large-scale fabrication, the key is preparation, precision, and respect for the material. When done right, bending stainless steel unlocks a world of design and engineering possibilities.

FAQs

304 stainless steel is considered the most bendable, thanks to its high ductility.

The best method depends on the application. For precision and repeatability, air bending is often the preferred choice in manufacturing. For curved shapes, roll bending is ideal, while hand bending works for small-scale or DIY projects.

Yes, stainless steel can be welded after bending. However, it is important to ensure the bend area is clean and free from stress cracks. Post-weld treatments such as passivation or polishing may be required to restore corrosion resistance and appearance.