Welding sheet metal might look simple at first glance, but anyone who has tried knows how quickly thin metal can warp, burn through, or weaken if not handled correctly. The good news? With the right techniques and tools, you can achieve clean, strong, and professional-quality welds (even on the thinnest sheets). In this guide, we will reveal the top 5 welding methods every welder should master, along with expert tips to help you avoid common mistakes and build confidence in your craft.

What is Sheet Metal Welding?

Sheet metal welding is a crucial process in metal fabrication, joining thin sheets from 30 gauge (0.3 mm) to 8 gauge (4.2 mm) using heat, pressure, or both. Unlike thick steel, it demands precise heat control to prevent burn-through, warping, and weak joints. Common methods include MIG, TIG, and spot welding, often supported by shielding gas, filler material, and clamping to stabilize the arc and reduce distortion. Proper ventilation and safety practices ensure strong, durable welds for use in automotive bodies, appliances, and industrial equipment.

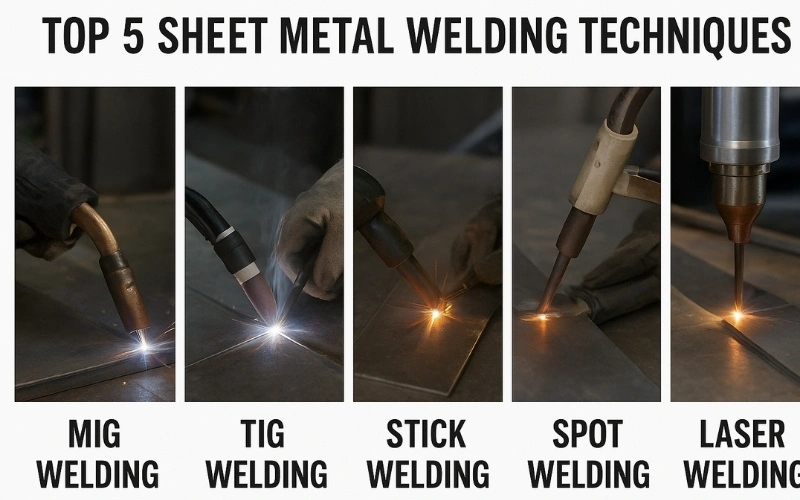

Top 5 Sheet Metal Welding Techniques

Mastering different welding techniques gives you flexibility for any project. Here are the top five methods you need to know:

MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), is the undisputed workhorse for sheet metal. It uses a continuously feeding wire electrode and a shielding gas, making it a fast, efficient, and relatively easy process to learn.

- How it Works: You pull a trigger on the MIG gun, which simultaneously starts feeding the wire electrode and flowing the shielding gas. The wire touches the workpiece, creating an electrical arc that melts both the wire and the base metal, forming a weld.

- Best For: Automotive repair, general fabrication, exhaust work, and any application where speed is a priority.

- Advantages: High speed, easy to learn, cost–effective, great for bridging small gaps.

- Disadvantages: Can produce spatter that requires cleanup, and the equipment is less portable than stick welding. The finish quality is good, but generally not as clean and smooth as a TIG weld.

TIG Welding

Gas Tungsten Arc Welding (GTAW), or TIG, is the process for artists and perfectionists. It uses a non-consumable tungsten electrode to create the arc and a separate, hand–fed filler rod to add material.

- How it Works: TIG welding is a two–handed process. One hand holds the TIG torch, which creates a very precise arc. The other hand dabs a filler rod into the molten puddle. A foot pedal is used to control the amperage, giving the operator incredible heat control.

- Advantages: Exceptionally clean and precise welds with no spatter, superior control over heat input, and can weld a wider variety of metals than MIG.

- Disadvantages: Very slow process, requires a high degree of operator skill and coordination, and the equipment is the most expensive.

- Best For: High–end fabrication, visible welds, stainless steel, aluminum, and any project where precision and appearance are the top priorities.

Spot Welding

Resistance Spot Welding (RSW) is the primary method used in high–volume automotive manufacturing. You see the results of this process every day in the small, circular divots along the door jambs and body panels of your car.

- How it Works: Two copper electrodes clamp onto the sheets of metal to be joined. A massive electrical current is passed through the electrodes, and the resistance of the base metal generates intense heat, which melts the metal at that “spot” and fuses the sheets. No filler metal is used.

- Advantages: Extremely fast (welds are made in fractions of a second), easily automated with robotics, clean process with no consumables.

- Disadvantages: Equipment is incredibly expensive and stationary, limited to lap joints, and not practical outside of an industrial setting.

- Best For: High–speed, automated manufacturing of products from lapped sheets of metal.

Laser Welding

Laser Beam Welding (LBW) is a high–tech, high–precision process that uses a focused beam of light to melt and join metal.

- How it Works: A powerful, highly concentrated laser beam is directed at the joint. The intense energy creates a deep, narrow weld with a very small heat–affected zone. This minimal heat input is a massive advantage for thin materials.

- Advantages: Extremely precise, very low heat input reduces warping, incredibly fast travel speeds, and can weld dissimilar materials.

- Disadvantages: The equipment has an exceptionally high capital cost and requires extensive safety precautions due to the high–powered laser.

- Best For: High–precision applications in the medical, aerospace, and electronics industries where minimal distortion is critical.

Stick Welding

Shielded Metal Arc Welding (SMAW), or Stick welding, is the oldest and simplest arc welding process. It uses a consumable electrode (the “stick” or “rod”) coated in flux, which burns to create a shielding gas.

- How it Works: An arc is struck between the flux–coated rod and the workpiece. The intense heat melts the rod, its flux coating, and the base metal together.

- Advantages: Very low equipment cost, extremely portable, excellent for welding outdoors or on dirty/rusty metal (not sheet metal).

- Disadvantages: Very difficult to use on thin materials, messy, and slow due to constant rod changes.

While technically possible for an expert with the right machine and rods (like a 1/16″ 6013), stick welding is highly discouraged for sheet metal. The process is too aggressive, the heat is hard to control, and the risk of burn-through is extremely high. It also produces a rough weld that requires extensive cleanup.

Essential Tools for Welding Sheet Metal

Having the right equipment is not just about making the job easier; it’s about making it possible. Using tools that are not suited for thin metal will lead to constant frustration and poor results.

Welding Machines

Not all welders are created equal. For sheet metal, you need a machine that offers fine control over the low end of the power spectrum.

- MIG Welder: Ideal for sheet metal work, especially with infinite voltage control for precise heat adjustment beyond fixed presets. Choose a quality machine that runs 0.023″ (0.6mm) wire smoothly.

- TIG Welder: The professional’s choice for precision welding. A foot pedal allows real-time amperage control, preventing burn-through. A pulse function is also valuable for reducing heat input.

- Inverter Technology: Modern inverter welders are lighter, more efficient, and provide a more stable, controllable arc than traditional transformer models, making them well worth the investment.

Consumables and Equipment

The machine is only part of the equation. Your choice of consumables directly impacts the quality of your weld.

- Welding Wire (MIG): For steel sheet metal, 0.023″ ER70S-6 wire is ideal. Its small diameter melts easily, making it perfect for low–amperage welding.

- Filler Rod (TIG): Use a thin ER70S-2 rod, 0.035″ or 0.045″, for precise material control during TIG welding.

- Shielding Gas: Protects the weld from contamination. Use C25 (75% Argon, 25% CO2) for MIG on steel. For TIG on steel or aluminum, use 100% Argon.

- Tungsten (TIG): A 1/16″ (1.6mm), 2% Lanthanated tungsten, sharpened to a point, offers stable arc control for DC TIG welding on steel.

- Angle Grinder: Essential for cleaning, shaping, and finishing, with various discs like flap wheels, wire brushes, and grinding wheels.

- Clamps: Critical for accurate fit-up and reducing warping. Stock up on locking pliers, C-clamps, and sheet metal clamps.

Safety Gear

Sheet metal welding can produce toxic fumes, high UV radiation, and flying sparks. Essential protective equipment includes:

- Auto-Darkening Helmet: This is your most important safety gear. It shields your eyes from harmful UV/IR radiation. Look for adjustable shade settings (9–13) and sensitivity controls.

- Fire-Resistant Clothing: Sparks can ignite regular cotton instantly. Wear a long-sleeve FR jacket made of leather or treated cotton.

- Welding Gloves: Use thick, gauntlet-style leather gloves to protect your hands from heat, sparks, and UV exposure.

- Respirator: Welding fumes are hazardous. A P100-rated respirator worn under your helmet is essential, especially for coated or galvanized metals.

- Ventilation & Fire Safety: Always weld in a well-ventilated area, and keep a Class ABC fire extinguisher within easy reach.

Tips for Successful Welding Sheet Metal

The difference between a warped panel and a perfect joint often comes down to technique and preparation.

Preparing the Metal

As the old saying goes, “Proper preparation prevents poor performance.” In welding, this is an absolute truth. You cannot create a good weld on bad material.

- Cleanliness is Paramount: Use an angle grinder with a wire wheel or flap disc to grind the weld area down to bright, shiny, bare metal. You must remove all rust, paint, mill scale, and any other contaminants.

- Degrease the Surface: After grinding, wipe the area with acetone or a dedicated degreaser. This removes any oils or residues that could get pulled into the weld, causing defects like porosity.

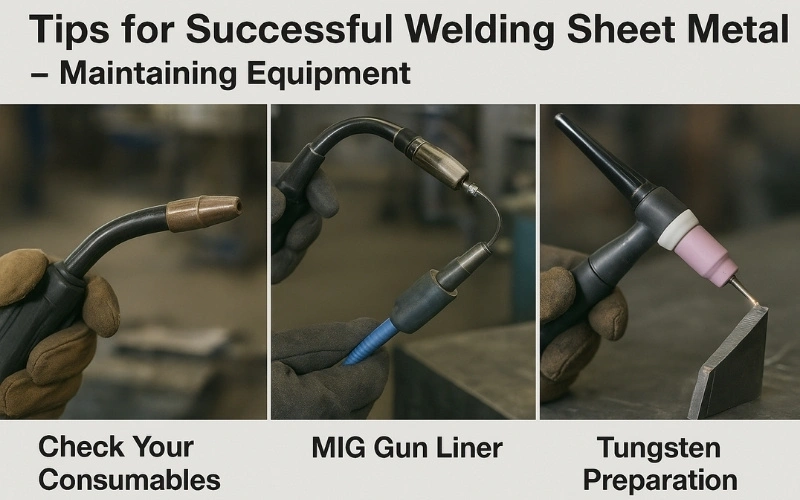

Maintaining Equipment

Your welder is a precision tool. If you don’t maintain it, it won’t perform correctly.

- Check Your Consumables: Regularly inspect your MIG gun’s contact tip. If the hole becomes worn or clogged with spatter, it will cause erratic wire feeding and an unstable arc. Keep it clean and replace it when it’s worn.

- MIG Gun Liner: The liner that guides the wire through the MIG cable can become clogged with debris over time. Periodically remove the wire and blow compressed air through the liner to clean it out.

- Tungsten Preparation: For TIG, a clean, sharp tungsten is essential for a focused arc. If you accidentally touch the tungsten to the weld puddle (known as “dipping the tungsten”), stop immediately, break the arc, and regrind the tungsten to a clean point.

Proper Joint Design

The way you fit two pieces of metal together has a huge impact on the final result.

- Aim for a Zero-Gap Fit: Any gap between your pieces forces you to use more heat and filler to bridge it, dramatically increasing the risk of burn-through and warping. Cut, grind, and file your pieces until they fit together perfectly.

- Choose the Right Joint: For beginners, a lap joint (one piece overlapping the other) is the most forgiving. A corner joint is also relatively easy. A butt joint (two pieces edge-to-edge) is the most difficult on thin metal, as it offers no room for error.

Techniques for Heat Control

This is the ultimate secret to mastering sheet metal.

- Tack Weld First: Place small tack welds every 1-2 inches along the joint to hold the panels in place and prevent them from shifting during welding.

- Stitch or skip welding: Avoid welding the joint in one continuous pass. Instead, weld short 1–2 inch sections in alternating spots to distribute heat and reduce distortion.

- Use a backing bar: Clamp a copper or aluminum bar behind the joint when possible. These metals act as heat sinks, drawing excess heat away to prevent burn-through.

- Move quickly: Use a quick, steady travel speed. Staying in one spot too long will overheat the metal and create holes.

Conclusion

Welding sheet metal may seem intimidating, but as we’ve seen, it’s a skill built on a foundation of understandable principles. By focusing on key areas such as understanding the material, using the right tools, selecting the proper technique, applying professional tips for preparation and heat control, you can simplify the process and achieve impressive results.

FAQs

To weld thin metal without burn-through, use low amperage, a short arc, and fast travel speed. Stitch or tack welding allows cooling between welds. Copper backing bars or heat sinks absorb excess heat and support the weld. Pulsed MIG or TIG improves heat control. Clean surfaces and precise fit-up ensure even heat distribution.

Welding thin metal demands precision. Use fine MIG wire (0,023–0,030) or small TIG electrodes (like 0,040) for better heat control. TIG is ideal for thin or non-ferrous metals due to its low amperage and arc precision. Clean surfaces, use proper shielding gas (argon for TIG; 75/25 argon/CO2 for MIG), and practice on scrap. Apply fast travel, intermittent welds, and backing to prevent burn-through.

Definitely yes. Sheet metal can be welded using methods like MIG, TIG, spot, laser, and more – depending on thickness, material, and application. MIG suits thicker sheets; TIG offers precision for thin metal. Spot and laser welding are ideal for clean, low-heat joins. Choice depends on equipment, skill, and project needs.