Sheet metal bending is a cornerstone of modern manufacturing, transforming flat metal sheets into complex shapes for everything from car parts to aerospace components. Whether you’re a beginner learning the basics, an engineer designing precision parts, or a manufacturer troubleshooting defects, understanding sheet metal bending is essential. In this guide, we will explore the processes, techniques, and best practices, offering you the knowledge to master bending and create high-quality parts. From bending methods to design tips, we’ve got you covered with practical insights and expert advice.

What is Sheet Metal Bending?

It is a sheet metal forming process that shapes flat sheet metal materials such as aluminum, stainless steel, and carbon steel into precise angles using press brakes or CNC press brakes with punch and die tooling. As a core method in metal fabrication and precision manufacturing, it depends on factors like material thickness, bend radius, K-factor, bend allowance, and springback control to ensure dimensional accuracy and tight tolerances. Common methods (including air bending, bottoming, and coining) vary in tonnage requirements, tooling geometry, and bend angle accuracy, supporting applications across automotive, electronics, and aerospace manufacturing.

Types of Sheet Metal Bending Processes

Understanding the various sheet metal bending processes is essential for selecting the appropriate method based on project requirements, material characteristics, and the desired precision level. Each method offers distinct advantages, limitations, and use cases. Below are the most widely used bending processes explained in detail.

Air Bending

Air bending is the most commonly used technique in modern fabrication shops due to its flexibility and lower tooling costs. In this process, the punch does not force the sheet metal to the bottom of the die but instead presses it partway, allowing air to support part of the bend. This partial penetration into the die cavity enables the operator to achieve various bend angles with a single punch and die set by simply adjusting the depth of the punch stroke. One of the downsides of air bending is the tendency for springback, which must be compensated for during setup. Despite this, the method is favored for its adaptability to different bend radii and angles without requiring a complete die set for each configuration.

Bottoming

Bottoming, sometimes referred to as bottom pressing or bottom bending, involves pressing the sheet metal into the bottom of the V-die until it fully conforms to the shape of the die. This method requires more force than air bending but provides a more consistent and precise bend angle due to the material being tightly held in place. Bottoming reduces the amount of springback compared to air bending, making it suitable for applications where angle accuracy is critical. However, the need for specific tooling for each bend angle and material thickness means that bottoming is less flexible and more costly in terms of die inventory.

Coining

Coining is a high-precision bending method where the punch applies enough pressure to plastically deform the metal, effectively imprinting or “coining” the shape of the die into the sheet. This intense pressure eliminates springback, resulting in extremely accurate and repeatable bends. Coining is ideal for parts requiring tight tolerances and minimal post-processing. However, the high force required in coining leads to increased tool wear and energy consumption, making it more suitable for high-volume production runs where tooling investment can be justified.

V-Bending / U-Bending

These traditional bending techniques derive their names from the shape of the dies used (V-dies and U-dies). V-bending is one of the most fundamental operations in metal fabrication, typically used with press brakes and available in air bending, bottoming, or coining forms. U-bending is similar but uses a U-shaped die, often to form channels or rounded profiles. Both methods can accommodate a variety of materials and thicknesses, and their versatility makes them staples in most workshops. The primary difference between the two lies in the final shape of the bend and the die geometry required.

Roll Bending

Roll bending is used to produce large-radius bends or cylindrical shapes using a set of three rollers arranged in a pyramid configuration. As the metal sheet passes through the rollers, it is incrementally bent until the desired curvature is achieved. This method is particularly effective for creating components such as tubes, pipes, or curved architectural panels. Roll bending allows for continuous bending over long sections, which makes it efficient for fabricating large-scale structural elements. The process requires a skilled setup to ensure uniformity and prevent deformation.

Materials Suitable for Sheet Metal Bending

Not all metals bend equally well. The best materials for sheet metal bending are ductile (like stainless steel, aluminum, steel, and black iron), meaning they can deform without cracking. Here’s a look at common options:

| Galvanized Steel | Stainless Steel | Aluminum | Black Iron | |

| Corrosion Resistance | High | Very high | High | Low |

| Strength | High | Very high | Moderate | High |

| Cost | Moderate | High | Moderate | Moderate |

| Applications | General HVAC ductwork in residential and commercial buildings | Corrosive environments, hospitals, and laboratories | Lightweight applications, outdoor installations | Kitchen exhaust systems |

| Advantages | Durable, cost-effective, readily available | Extremely durable, resists corrosion, long lifespan | Lightweight, corrosion-resistant, easy to install | Withstands high temperatures, durable |

| Disadvantages | Can corrode in highly corrosive environments | More expensive than galvanized steel | Lower strength than steel, may require thicker gauges for larger ducts | Susceptible to corrosion without proper maintenance and cleaning |

Material properties like thickness, strength, and ductility affect bending. For example, thicker materials need larger bend radii to prevent cracking, while brittle materials may require special techniques.

Tools and Equipment for Sheet Metal Bending

The right tools and equipment are crucial for successful sheet metal bending. When choosing tooling, please consider material thickness, bend radius, and desired precision to choose the best one for your project.

Press Brakes

Press brakes are the workhorses of sheet metal bending, using a punch and die to create precise bends. They come in three types:

- Manual: Affordable but labor-intensive, suitable for small-scale projects.

- Hydraulic: Powerful and versatile, ideal for thick materials.

- CNC: Computer-controlled for high precision and automation, perfect for complex parts.

Dies

Dies are critical tools that define the shape and radius of a bend. They come in many forms, such as V-dies, U-dies, gooseneck dies, offset dies, and hemming dies, among others. V-dies are the most commonly used, available in various angles and widths to accommodate different bending requirements. Gooseneck dies are specially designed for return flanges, while offset dies allow for bending steps or z-forms in one hit. Hemming dies are used to flatten the metal, often in automotive applications. The proper selection of a die depends on the geometry of the part, the material thickness, and the desired bend accuracy.

Roll Benders

Roll benders are used in operations where large-radius or cylindrical bending is needed. The equipment typically consists of three rollers – two fixed and one adjustable – that gradually shape the metal as it passes back and forth through the machine. This gradual forming process is ideal for creating parts like tanks, tubing, or curved railings. Roll benders can be manually operated for simple curves or powered with CNC controls for precision and repeatability in complex designs.

Hand Tools and Gauges

In smaller-scale operations or for touch-up and prototyping work, hand tools like bending brakes, mallets, and forming pliers play a vital role. Precision gauges and protractors are also used to measure angles during and after bending to ensure accuracy. While not suitable for high-volume production, these tools provide flexibility and control in custom or one-off tasks. They are often used during setup, quality control, and rework processes.

Essential Bending Calculations

Accurate calculations are the foundation of successful sheet metal bending. Several parameters must be considered to ensure the final component matches design expectations and minimizes trial-and-error during fabrication. These calculations help compensate for material behavior during deformation and ensure precision.

Bend Allowance

Bend allowance (BA) is the arc length of the bend and represents the amount of material that must be added to the total length of the flat sheet to account for the bend. This value depends on the bend angle, material thickness, inside radius, and the material’s mechanical properties. The standard formula for calculating bend allowance is:

BA = (π/180) × A × (R + K × T)

Where:

- BA is the bend allowance

- A is the bend angle in degrees

- R is the inside bend radius

- T is the material thickness

- K is the K-factor (typically between 0.3 to 0.5)

For example, calculating the bend allowance for a 90° bend in 1mm thick aluminum with a 2mm inside radius and K-factor of 0.44:

BA = π/180 × 90 × (2 + 0.44 × 1) ≈ 3.83 mm

This means the bend itself consumes 3.83mm of material length, critical information when determining flat pattern dimensions.

Bend Deduction

Bend deduction (BD) is the amount by which the total length of the material must be reduced to achieve the desired final dimensions. It takes into account the stretching and compression of the material during the bending process.

BD = 2 × Outside Setback – BA

The outside setback (OSSB) can be calculated using:

OSSB = (T + R) × tan( A / 2)

These values help designers accurately lay out flat patterns before cutting and bending.

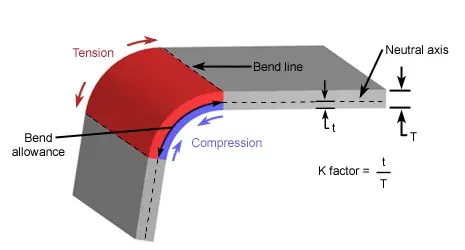

K-Factor

The K-factor is a ratio that determines the position of the neutral axis within the material thickness, typically ranging from 0.3 to 0.5. It depends on the material, thickness, and bending method. For example:

- Soft aluminum: K ≈ 0.33

- Mild steel: K ≈ 0.44

- Stainless steel: K ≈ 0.4

- Hard brass: K ≈ 0.38

- Copper: K ≈ 0.5

Springback Estimation

Springback occurs when the material partially returns to its original shape after the bending force is removed. This must be predicted and compensated for by overbending. The amount of springback depends on the material’s elasticity and the bend radius. A common estimation approach is to add a few degrees to the programmed angle in air bending to account for this phenomenon.

Learn more: Common sheet metal bending defects and how to fix them

Design Considerations for Sheet Metal Bending

Designing for sheet metal bending requires careful planning to ensure successful outcomes. Here are some key best practices to follow.

Minimum Bend Radius

Always use a bend radius at least equal to the material thickness to prevent cracking. For example, a 2 mm-thick aluminum sheet should have a minimum bend radius of 3 mm (1.5x thickness). Guidelines include:

- Steel: 1x thickness

- Aluminum: 1.5x thickness

- Copper: 0.5x thickness

Hole Placement Near Bends

Placing holes too close to bends can cause distortion or cracking. As a rule of thumb, keep holes at least 2-3 times the material thickness away from the bend line. For example, a 1 mm-thick sheet should have holes at least 2-3 mm from the bend.

Avoiding Sharp Bends

Sharp bends (zero or near-zero bend radius) weaken the material and are difficult to manufacture. Instead:

- Use a bend radius at least equal to the material thickness

- Add relief cuts for tight corners

- Consider alternative forming methods for sharp angles

Designing for Manufacturability

To make parts easier and cheaper to produce, follow these tips:

- Use uniform bend radii to simplify tooling.

- Maintain consistent material thickness to avoid setup changes

- Avoid complex bend sequences that require multiple setups

- Collaboration with manufacturers early in the design process can also optimize manufacturability

Conclusion

Sheet metal bending is both a science and an art. It requires precise calculations, appropriate tooling, and a deep understanding of material behavior.. From foundational techniques like air bending and coining to the selection of specialized equipment and accurate bend allowances, every aspect of the process influences the quality and functionality of the final product. By understanding the variables such as bend radius, springback, and tooling configurations, engineers and manufacturers can achieve high precision, reduce waste, and maintain structural integrity across diverse applications.

FAQs

To lay out sheet metal for bending, start by calculating the bend allowance using the correct formula for your material and bend parameters. Subtract the bend deduction from the total length of the flat pattern to determine where to place bend lines. Use a layout tool or CAD software to mark precise locations on the sheet, accounting for radii and bend direction. Always double-check the orientation to avoid mirrored or inverted parts.

Sheet metal is relatively easy to bend when the correct process and tools are used. Thin and ductile materials like aluminum and mild steel bend more easily than hardened or thick metals. Ease of bending also depends on proper die selection, bend radius, and machine settings. Improper setup or unsuitable materials can make bending difficult or lead to defects.

One commonly used rule is that the minimum inside bend radius should be equal to or greater than the material thickness. Additionally, holes or notches should be placed at least two times the material thickness away from any bend line to prevent deformation. Following accurate bend allowance calculations and using the correct K-factor are also critical to ensure a successful outcome.