Stainless Steel Stamping

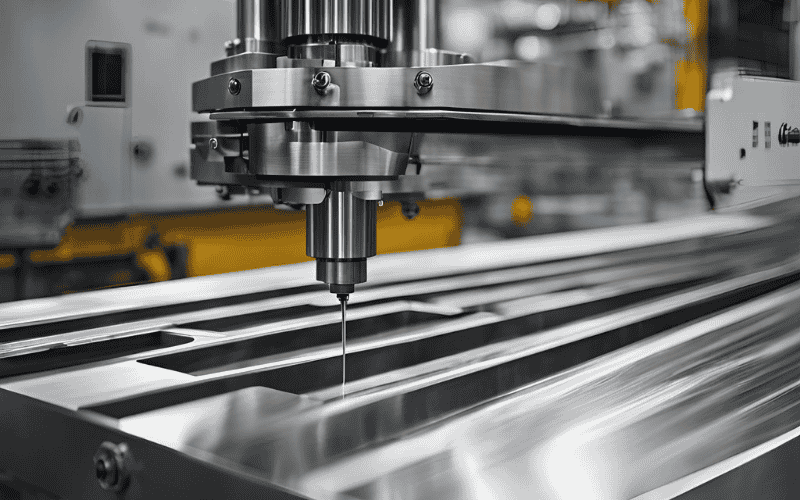

Stainless steel stamping is a crucial metal forming process used to transform flat stainless steel sheets into a wide variety of shapes, using a specialized stamping press. This process is highly valued for its precision, efficiency, and ability to produce complex parts with excellent repeatability. The inherent properties of stainless steel, such as its corrosion resistance, strength, and durability, make it a popular choice for stamping applications across numerous industries.

Surface Treatments & Finishes

We provide a range of surface treatments and finishes to improve both appearance and functionality:

Surface Treatments

We offer a wide range of surface treatments to enhance the appearance, durability, and functionality of your products, ensuring they meet your exact specifications

- PVD

- Electropolishing

- pickling and passivation

- ED coating

- Powder coating

- Shot blasting

- Sandblasting

- Alu grit or glass bead blasting

- Chemical (electro) polishing

- Mechanical polishing

- Ultrasonic cleaning

- Silk screen printing

Surface Finishing

We offer the following surface finishing for stainless steel:

- 2B Finish

- BA (Bright Annealed) finish (normal polished)

- Mirror finish (mirror quality polished)

- Hairline finish

- #4 finish, with grit 180/240/320/400

- CD overlay (sunny profile circle polished)

- #1 finish (mill finish) for hot rolled stainless steel

If your surface finish is not mentioned in the options above, please feel free to ask us. Our suppliers have a lot of other options available, but the most common ones are mentioned above.

Applications Across Industries

Stainless steel stamping finds applications in a wide range of industries, including:

- Automotive: Body panels, trim components, exhaust systems.

- Medical: Surgical instruments, implants, medical devices.

- Aerospace: Structural components, engine parts, turbine blades.

- Electronics: Housings, connectors, heat sinks.

- Construction: Architectural elements, fasteners, brackets.

- Food Processing: Equipment components, storage containers.

Advantages of Utilizing Stainless Steel Stamping

Stainless steel stamping offers numerous benefits, making it a preferred manufacturing choice:

- Lasting Durability: Its inherent strength ensures parts withstand tough conditions and frequent use, outliving components made from other materials.

- Corrosion Resistant: A protective chromium oxide layer makes it perfect for humid or corrosive settings like marine and chemical industries.

- Hygienic & Easy to Clean: Its smooth surface is simple to sanitize and ideal for medical devices, food processing, and kitchens.

- Sustainable Choice: Highly recyclable, stainless steel minimizes environmental impact.

- Design Versatility: Stamping accommodates diverse shapes and sizes, offering design flexibility for various applications.

High Standards and Certifications

We ensure the highest standards in our products and services through strict certifications and processes to meet all customer requirements

- ISO 9001 Certified Partners: We exclusively work with factories adhering to ISO 9001 quality standards, ensuring they meet the highest quality standards.

- In-House Expertise: Our partners routinely perform in-house adjustment and maintenance of welding equipment, machines, fixtures, and molds (die casting and injection molding) to maintain precision and quality

- Global Compliance: We only work with companies that are RoHS and Reach compliant.

Why Choose Us as Your Stainless Steel Stamping Partner?

As a leading sheet metal, die casting, and stamping factory in Vietnam, ABC Vietnam stands out as the ideal partner not only for your stainless steel stamping but also for aluminum and steel stamping needs. Our extensive experience, commitment to quality, and customer-centric approach set us apart. Here are some reasons why you should choose ABC Vietnam as your stainless steel stamping partner:

- We have extensive experience in stainless steel stamping, serving a wide range of industries including electronics, furniture, and renewable energy.

- Our team of engineers and technicians is highly skilled and knowledgeable in all aspects of the stamping process, ensuring that your parts are produced to the highest standards.

Unwavering Quality

We are committed to providing our customers with the highest quality stainless steel stampings. We utilize state-of-the-art equipment and adhere to strict quality control procedures throughout the entire manufacturing process. This ensures that you receive parts that are consistent, reliable, and meet your exact specifications.

Customer-Centric Approach

We understand that your business is unique, and we take the time to understand your specific needs and requirements. We collaborate closely with you throughout the entire project journey, from initial conception to final delivery, ensuring timely completion and adherence to budgetary constraints.

Competitive Pricing

We offer competitive pricing on all of our stainless steel stamping services. We are confident that you will find our prices to be fair and affordable, without compromising on quality.

Commitment to Sustainability

We are committed to operating our business in an environmentally responsible manner. We utilize energy-efficient technologies and recycle all scrap metal, minimizing our environmental impact.

Stainless steel sheet metal pressed, stamped, or deep drawn, manufactured in Vietnam

Sealing

rings

Commonly used in industrial applications such as piping, flanges, or machinery to ensure a leak-proof seal

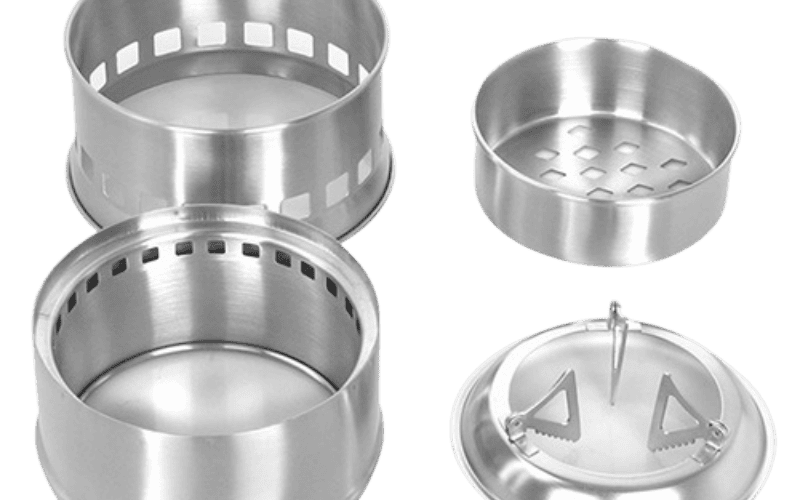

Camping

stove

Designed for outdoor use and operates by burning wood or other biomass materials to provide a flame for cooking or heating

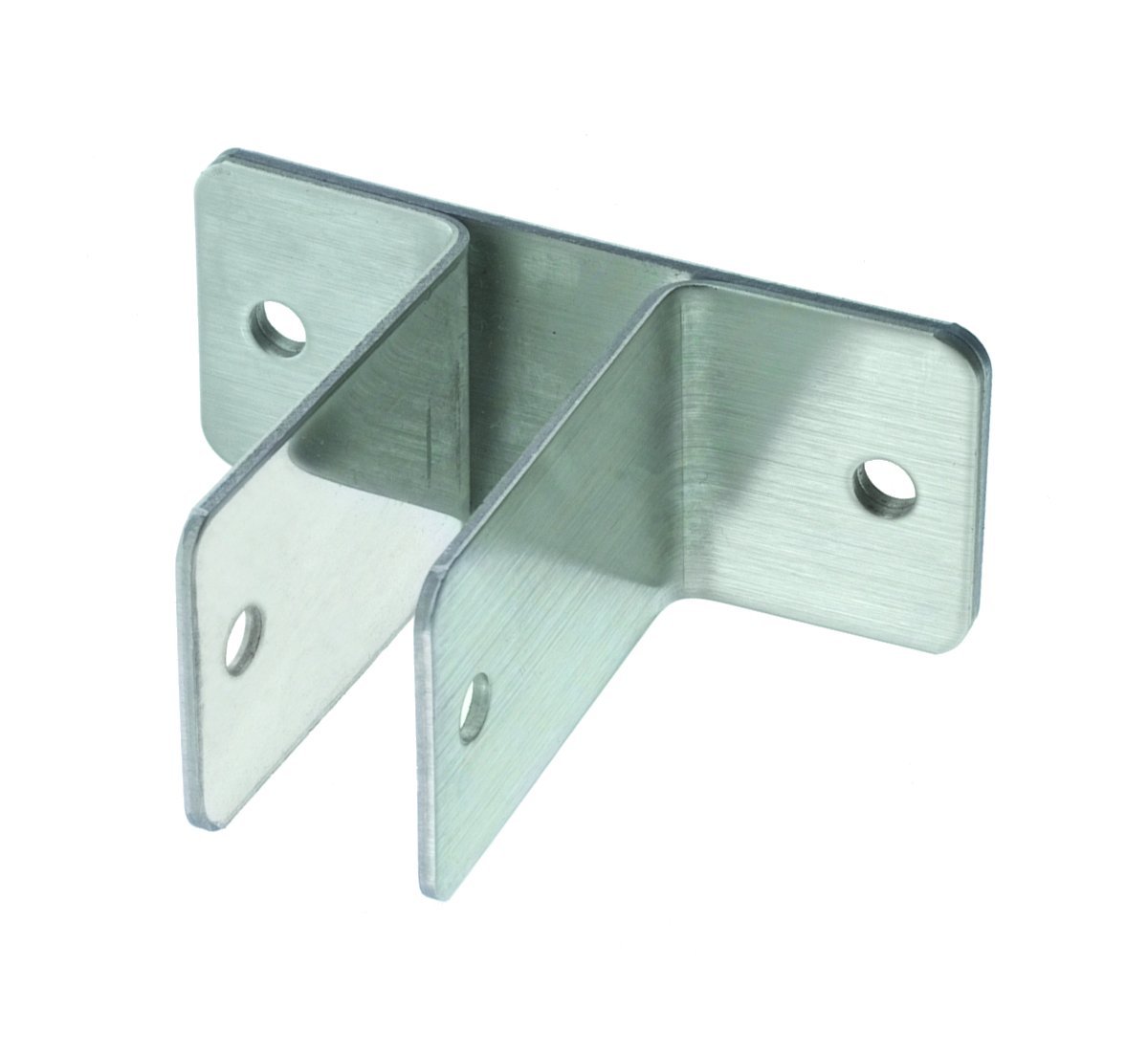

Two-ear

wall bracket

Provides a secure and versatile mounting solution for handrails, pipes, and shelves, suitable for indoor and outdoor applications

Spinning

deflector

Commonly used in HVAC systems or industrial ventilation to control and distribute airflow in a specific pattern

Hard drive

mounting bracket

Securely hold and position a hard drive inside a computer case or storage enclosure, ensuring proper alignment and support

Floor drain

gate

Prevent debris from entering and clogging the drain while allowing water to flow freely, help maintain proper drainage, and keep the area clean