CNC Machining in Vietnam: Precision and Excellence

At our state-of-the-art factory in Vietnam, we specialize in high-precision CNC machining. With a commitment to quality and adherence to strict standards, we deliver exceptional results for a wide range of industries.

Why Choose Our CNC Machining Services?

We deliver excellence in every project by leveraging our global reach, cutting-edge technology, and material expertise.

- Global Reach: As a leading CNC machining company, we serve clients worldwide. From the semiconductor industry to aircraft manufacturers, our expertise spans diverse sectors.

- Cutting-Edge Technology: Our facility boasts 5-axis milling, CNC turning, wire EDM, and more. We leverage advanced machinery to achieve precision in every cut.

- Materials Expertise: Whether it’s aluminum, steel, or stainless steel, we handle a variety of materials. Our skilled team ensures flawless machining for each part.

Our CNC Machining Capabilities

Our CNC machining capabilities are designed to meet the most demanding requirements. Explore our advanced solutions, from 5-axis milling to wire EDM, tailored for precision and complexity.

5-Axis Milling

Our CNC machines offer intricate multi-axis milling capabilities. From complex geometries to tight tolerances, we deliver top-notch results.

CNC Turning

Precision turning is our forte. We create components with exact specifications, meeting the highest industry standards.

Wire EDM

Our wire-cutting CNC machine ensures precise shapes and intricate details. It’s ideal for intricate parts and fine finishes.

Surface Finishing Possibilities

Whether your sheet metal fabrication products need to be mounting brackets, electronic cabinets or enclosures, machinery and device parts, kiosks, shrouds, housings, welding assemblies, or other precision parts, we organize your complete sheet metal fabrication supply chain in Vietnam. From mono parts to complete products, including surface treatment (powder coating and plating). We assemble, quality control, and packaging, and we organize for you in our own warehouse and distribution center, so you don’t have to worry about any quality issues. Due to this process, ensure we meet your company’s quality demands and on-time delivery. Ready to experience the benefits of sheet metal fabrication in Vietnam? Contact us today to discuss your project requirements.

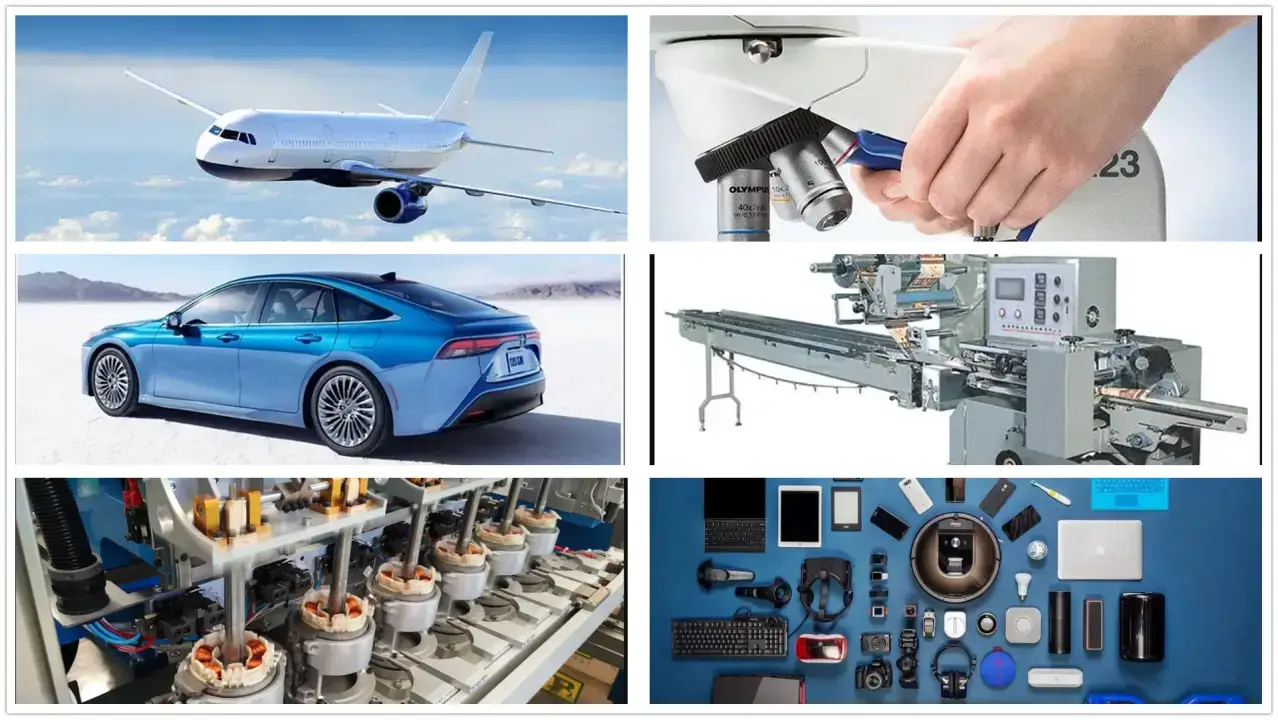

Applications of Die-Cast Products

Moreover, the die-cast products we manufacture with our certified partners in Vietnam find their use in a diverse range of fields, including:

Automobile & Automotive

We work together with Vietnamese aluminum die casters for the automotive industry. These are Vietnamese and foreign-owned companies in Vietnam

Medical Equipment & Devices

Today a lot of casted parts are being used in medical devices. Die-cast housings from aluminum are extremely durable and very good to apply.

Construction & Scaffolding

CNC machining manufactures durable components for power plants, turbines, and renewable energy systems. Parts like turbine blades and pump housings withstand extreme conditions, improving energy production efficiency and reducing costs.

Renewable Energy

As the world shifts toward renewable energy sources, aluminum die casting is playing an increasingly important role in the production of components for solar panels, wind turbines, and electric vehicle (EV) charging stations. The structural integrity, lightweight properties, and corrosion resistance of aluminum make it an ideal material for renewable energy applications.

Advantages and Considerations

Advantages

Aluminum die casting presents numerous advantages, including:

- High Production Rates: Ideal for large-scale manufacturing due to its efficiency.

- Complex Shapes: Die casting allows for the creation of intricate geometries and thin walls that would be difficult or impossible to achieve with other manufacturing methods.

- Dimensional Accuracy: Produces parts with tight tolerances, minimizing the need for secondary machining.

- Excellent Surface Finish: Smooth surfaces can be obtained directly from the die.

- Strength and Durability: Die-cast aluminum parts exhibit high strength-to-weight ratios.

Factors to Consider

However, there are some factors to consider:

- Initial Tooling Cost: Designing and manufacturing a die can be expensive.

- Limited Part Size: The maximum size of die-cast parts is constrained by the machine’s capacity.

- Porosity: Internal voids or porosity can occur, potentially affecting structural integrity.

Why CNC Machining Matters?

CNC machining plays a very important role in modern manufacturing for CNC and die-casting products. It enables efficient production, consistent quality, and stable planning. Whether you’re designing automotive components,solar-related products, or other die-cast parts, our CNC services have the full cover to produce your products in-house.

At ABC Vietnam Manufacturing, we take pride in our post-processing of precision CNC machining for die-cast parts and single-machined products. We have ISO 9001:2015 certification, which can ensure our quality. We are trusted for our reliable production and clear communication. Contact us today for a quotation

FAQs

We use advanced inspection equipment, in-process checks, and quality systems (like ISO and ASTM standards) to ensure parts meet dimensional and surface requirements consistently.

Definitely yes. From low-volume prototypes to larger production batches, we scale processes and offer flexible lead times to suit your project needs.

Yes, we do. Our engineers review designs and suggest improvements for manufacturability, cost savings, and reduced cycle time before production starts.