Brass Stamping Service for Precision Components

Brass stamping is an important manufacturing process that is used to create high-precision components for various industries. At ABC Vietnam, we specialize in delivering custom brass stamping services tailored to meet diverse client needs. This article explores everything you need to know about its process, applications, benefits, and why our services stand out in the market.

What is Brass Stamping?

Brass stamping is the process of shaping brass sheets or coils into specific forms using specialized tools known as dies. The stamping process involves applying high-pressure machinery to press or cut the brass into the desired design. This method is commonly used to create parts for industries such as electronics, automotive, construction, and jewelry.

Brass is suitable for stamping due to its unique properties:

- Adaptability: Brass is easy to shape, allowing for intricate and precise designs.

- Corrosion Resistance: Brass resists tarnishing and oxidation, making it ideal for outdoor and marine applications.

- Electrical Conductivity: Its conductive properties make it indispensable in electronics manufacturing.

- Aesthetic Appeal: Brass offers a polished, gold-like finish that enhances the appearance of products.

By combining these qualities, brass stamping strikes a balance between form and function, making it an essential process across a variety of industries.

The Brass Stamping Process

Brass stamping involves several key steps, which ensure precision and consistency in the final product

Design

Custom dies are created to match the exact specifications of the brass component. These dies are typically made of hardened steel to withstand high-pressure stamping.

Material Selection

Manufacturers choose the appropriate alloy for the application. Common alloys include:

- C260 (Cartridge Brass): Known for excellent corrosion resistance and workability.

- C280 (Muntz Metal): Offers high strength and durability for heavy-duty applications.

Stamping Process

The brass sheet is placed in the stamping machine, where it undergoes various techniques such as blanking, embossing, bending, or deep drawing. These operations shape the brass into the desired form.

Finishing

After stamping, components may be polished, plated, or coated to enhance their durability and appearance. Some finishes, such as gold plating or powder coating, are chosen for aesthetic purposes, while others are functional.

Advantages of Using Brass in Stamping

Brass is a superior material for stamping, and its advantages are undeniable

| Material | Brass | Steel | Aluminum |

| Corrosion Resistance | Excellent | Good, but may require coating | Good |

| Adaptability | High | Moderate | Very High |

| Conductivity | Excellent | Low | |

| Cost | Moderate | Low | High |

| Recyclability | Highly recyclable | Recyclable | Highly recyclable |

Compared to other materials like steel or aluminum, brass strikes a balance between durability and cost-effectiveness. These properties make it a top choice for precision components across industries.

Common Applications

Industries widely employ brass stamping due to its reliability and adaptability. Some prominent applications include:

- Electrical and Electronics: Brass’s excellent conductivity makes it suitable for connectors, terminals, and switches.

- Automotive Components: From brackets to decorative trims, brass parts enhance both functionality and aesthetics in vehicles.

- Decorative Hardware: It enables intricate designs for handles, knobs, and architectural elements.

- Plumbing and Heating Systems: Corrosion resistance ensures brass’s suitability for fittings, valves, and other plumbing components.

Our Capabilities

At ABC Vietnam, we pride ourselves on advanced brass stamping capabilities that meet global quality standards. Our technical expertise is unmatched, as we utilize advanced stamping machinery capable of handling brass sheets of various thicknesses. These machines ensure precision tolerances to meet even the most stringent client requirements, providing reliability and consistency across projects.

When it comes to production capacity, we cater to both high-volume production needs and small-batch, custom projects. This flexibility allows us to address the specific demands of a diverse client base, ensuring scalability without compromising quality.

Quality assurance is the most important feature of our operations. We implement rigorous quality control processes at every stage of production, ensuring that each component meets global standards. Additionally, our certifications underscore our dedication to excellence and reinforce our clients’ trust in our capabilities.

Why Choose ABC Vietnam?

When it comes to precision brass stamping, we stand out as a trusted partner for manufacturers across industries.

Expertise and Experience

With over 20 years in the industry, we specialize in delivering high-quality brass-stamped components that meet the most demanding specifications.

Advanced Technology

Our state-of-the-art facilities are equipped with CNC machines, hydraulic presses, and precision tooling to ensure accuracy and consistency.

Custom Solutions

From prototyping to large-scale production, we offer tailored solutions to meet your unique needs. Whether you need intricate decorative designs or functional components, we’ve got you covered.

Quality Assurance

As we mentioned above, quality assurance is the heart of our operation. Every component we produce undergoes rigorous quality checks to ensure it meets industry standards. Our commitment to quality is reflected in our customer satisfaction ratings.

Sustainability

We prioritize environmentally friendly practices, including recycling brass scrap and using energy-efficient processes.

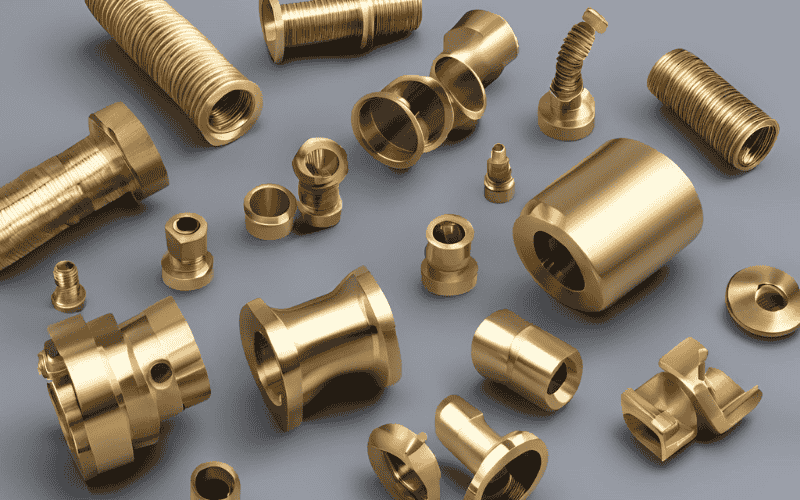

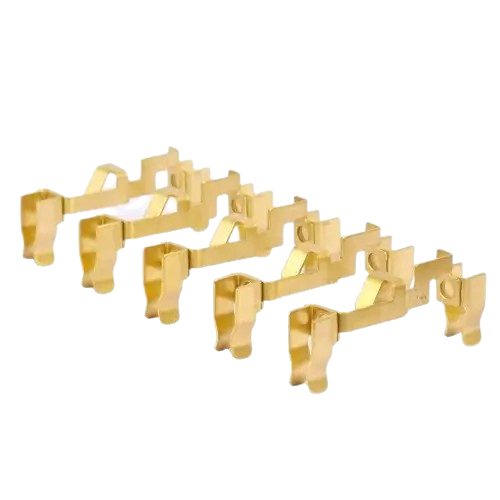

Brass sheet metal pressed, deep drawn & stamped products we manufactured in Vietnam

Pressing

bracket

Formed brass (or plated stamping part) pressing bracket

Electric socket

backplate

The electric socket back plate was produced with a deep drawing machine

Perforated

strainer

Perforated strainer produced with a deep drawing machine

Brass

canopy

Typically used as a decorative or functional cover, often in lighting, architecture, or furniture design

Brass

bearings

Used in mechanical and industrial applications to reduce friction between moving parts

Metal

electrical connectors

Used in electrical applications to establish connections between conductive elements

FAQs

We use precision tooling and advanced press control, combined with rigorous quality inspections, to maintain tight tolerances and consistent part quality across batches.

While tooling requires upfront investment, brass stamping becomes highly cost-effective for medium and large production runs due to high speed and low per-unit costs.

Contact us now for a consultation or quote!