Aluminum Stamping in Vietnam

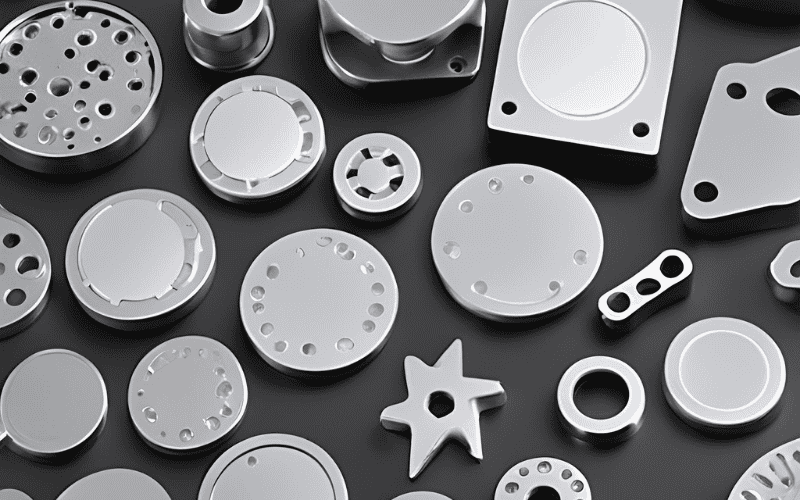

Stamping (or pressing) aluminum involves placing flat sheet metal, either in blank or coil form, into a stamping machine. Here, a tool and die set with a specific pattern, shape, or form deforms or cuts the metal into the desired shape. This process can be accomplished using either a single-step die set or a fully automatic progressive die set. Stamping encompasses a variety of sheet-metal forming manufacturing processes, including punching, blanking, embossing, bending, flanging, and coining. These operations can be performed as a single-stage operation, where every stroke of the press produces the desired form on the sheet metal part, or through a series of stages for more complex shapes.

The Process of Stamping Aluminum

The aluminum stamping process typically involves working with tubes and sheet metal, but it can also be applied to various other materials. Aluminum is a preferred material for stamping due to its excellent formability, lightweight, and corrosion resistance. The process begins by feeding aluminum sheets or coils into the stamping machine. The machine then uses a series of tools and dies to shape, cut, and form the aluminum into the desired components.

Applications of Stamping Aluminum

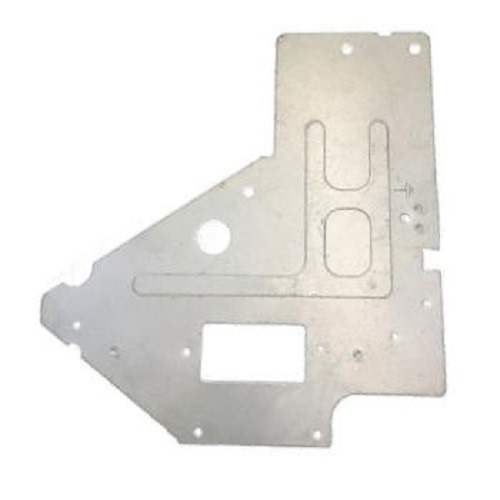

We specialize in organizing the manufacturing and fabrication of custom-designed sheet metal brackets in medium to large batches. The aluminum sheet-metal brackets we produce are used in a wide range of fields, demonstrating the versatility and adaptability of our stamping process. Some common applications include:

- Switchgear assemblies: Ensuring the safe and efficient operation of electrical power systems.

- AV mounts: Providing secure and adjustable support for audio-visual equipment.

- LED housings: Protecting and enhancing the performance of LED lighting systems.

- Enclosures: Safeguarding electronic components and systems from environmental factors.

- Custom brackets: Offering tailor-made solutions for specific applications across industries.

Advantages of Using Aluminum for Stamping

Aluminum stands out as a preferred material for stamping due to its unique combination of properties, offering both versatility and performance across various applications

- Effortless Shaping: Aluminum’s flexibility allows manufacturers to easily shape it into intricate designs during stamping.

- Lightweight: Aluminum’s low density makes it ideal for applications where weight reduction is crucial.

- Corrosion resistance: Aluminum naturally forms a protective oxide layer, providing inherent resistance to corrosion.

- Flexibility: You can stamp aluminum into a wide variety of shapes and sizes, making it suitable for countless applications.

- Adaptability: Aluminum’s properties allow it to be easily integrated into different manufacturing processes.

Secondary Treatments

To enhance the properties and appearance of the stamped aluminum parts, we offer a variety of secondary treatments, including:

- ED Coating: Provides excellent corrosion resistance and adhesion properties.

- Powder Coating: Offers a durable, high-quality finish that is resistant to chipping, scratching, and fading.

- Anodizing: Available in Type I, II, and III (Class 1 and Class 2) to improve corrosion resistance and surface hardness.

- Chromate (Cr3): Enhances corrosion resistance and provides a good base for painting or powder coating.

- Electroless Nickel (EN) Plating: Offers uniform thickness and excellent corrosion resistance

These secondary treatments ensure that the stamped aluminum parts meet the highest standards of quality and durability.

Why Choose ABC Vietnam for Your Aluminum Stamping Products?

At ABC Vietnam, we combine years of experience with cutting-edge technology to deliver top-quality stamped components, whether in aluminum or other suitable materials such as steel or brass. Our commitment to precision, efficiency, and customer satisfaction sets us apart. We understand the unique demands of each industry and tailor our solutions to meet your specific needs. From prototyping to large-scale production, we are your trusted partner for all your stamping requirements.

Aluminum pressed and stamped products manufactured in Vietnam

Cover

plate

Aluminum cover plate stamping in Vietnam

Aluminum

bucket

Aluminum pressing deep drawing bucket part

Shelf

led light

Powder-coated shelf led light housing enclosure

Spinning

light

Vietnam stamping metal spinning light reflector

Aluminum

blank

Aluminum stamping blank products

Shelf

enclosure

Aluminum shelf blankets for precision parts