Precision, speed, and clean welds are now essential in modern manufacturing, pushing more industries toward laser welding for reliable, high-performance joints. However, choosing the right laser type, controlling heat input, and preventing defects can be challenging without proper guidance. This concise guide explains the process, key methods, benefits, and practical tips to help you confidently apply laser welding in real production. Let’s explore how to optimize results and elevate your fabrication capabilities.

What is Laser Welding?

Laser welding, or laser beam welding, is an advanced joining process that uses a focused laser beam to fuse metals or plastics with deep, precise welds and minimal heat distortion. Unlike traditional arc or gas welding, it employs fiber lasers, CO2 lasers, or solid-state lasers for applications in automotive, aerospace, electronics, and medical device manufacturing, where speed, automation, and high-strength joints are essential. While it offers speed, accuracy, and strong joints, challenges like high cost, porosity, and material limits require careful beam control and shielding gas management.

Read more: What is fiber laser welding: All you need to know

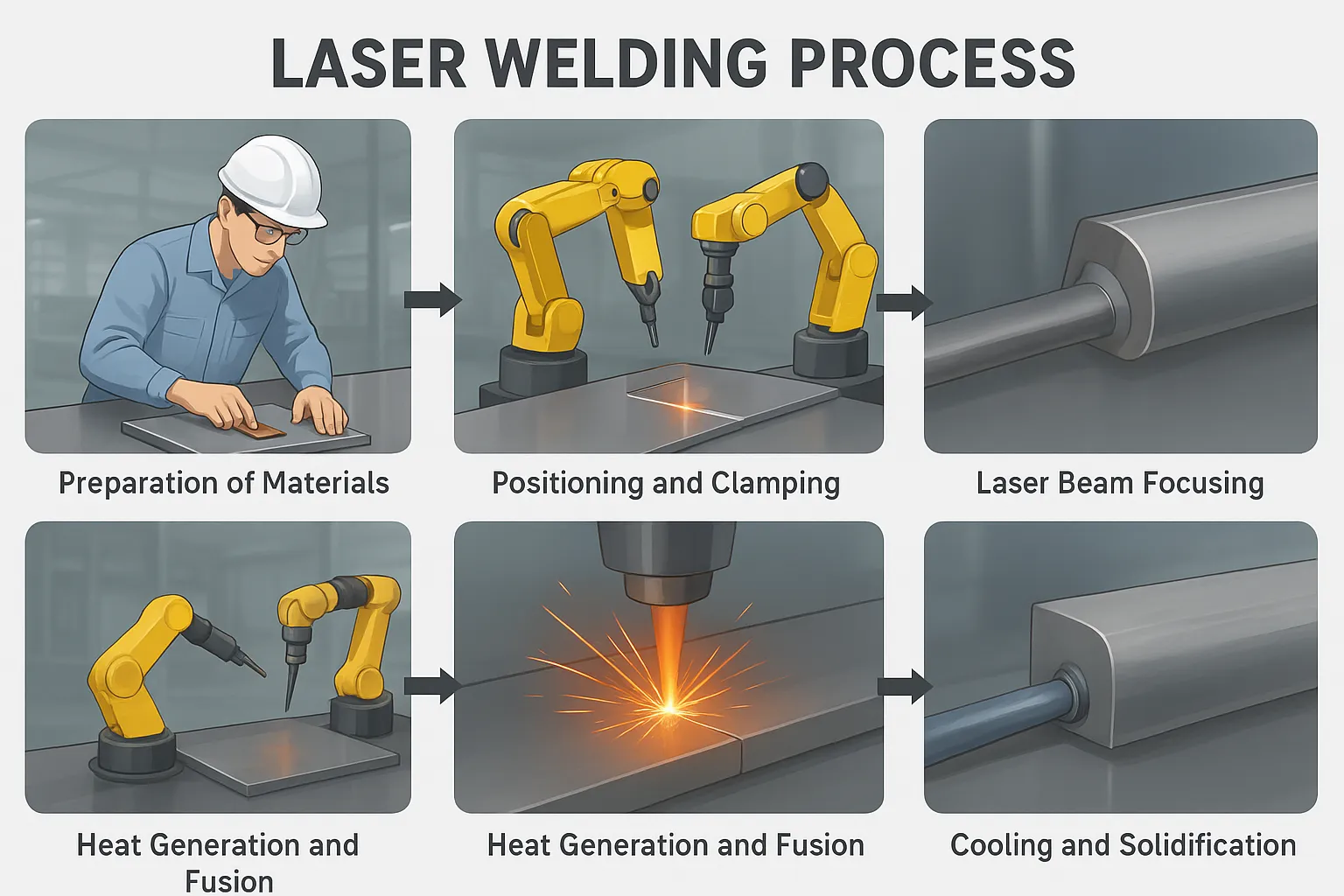

Laser Welding Process

The laser welding process involves several stages. Each step must be optimized to ensure a strong, defect-free joint.

Preparation of Materials

Before welding begins, surfaces must be thoroughly prepared to ensure a clean, defect-free weld. Any contamination such as oil, rust, oxides, or coatings, can cause porosity and weaken the joint. Proper preparation ensures consistent quality and durability.

- Remove contaminants using solvents, abrasives, or chemical cleaning

- Ensure surfaces are flat and aligned to minimize gaps

- Use mechanical fixtures or clamps to hold parts in place

Positioning and Clamping

Accurate alignment is crucial in laser welding since the laser beam is highly concentrated. Even small deviations can cause incomplete fusion or weak joints.

- Secure workpieces with jigs or fixtures to prevent movement

- Ensure proper joint design (butt, lap, or overlap configuration)

- Use automated systems for repeatability in high-volume production

Laser Beam Focusing

The laser must be precisely focused to deliver maximum energy at the joint area. The beam diameter, focus position, and power density determine weld penetration and quality.

- Adjust the focus spot size according to the material thickness

- Use lenses or fiber-optic systems for accurate delivery

- Regularly calibrate focusing optics for consistent results

Heat Generation and Fusion

Once the laser is focused, intense heat melts the joint area, creating a molten pool that fuses the materials. Unlike arc welding, this process produces narrow, deep welds with minimal heat spread.

- Control laser power to match material type and thickness

- Use shielding gases (argon, helium, nitrogen) to prevent oxidation

- Monitor weld pool stability with sensors or real-time cameras

Cooling and Solidification

After welding, the molten pool solidifies rapidly, forming a strong metallurgical bond. Proper cooling minimizes cracking and residual stress in the joint.

- Allow natural cooling for thin sections; use active cooling for thicker parts

- Avoid rapid cooling that may cause brittleness

- Inspect welds visually and with non-destructive testing for quality assurance

What Are Common Laser Welding Methods?

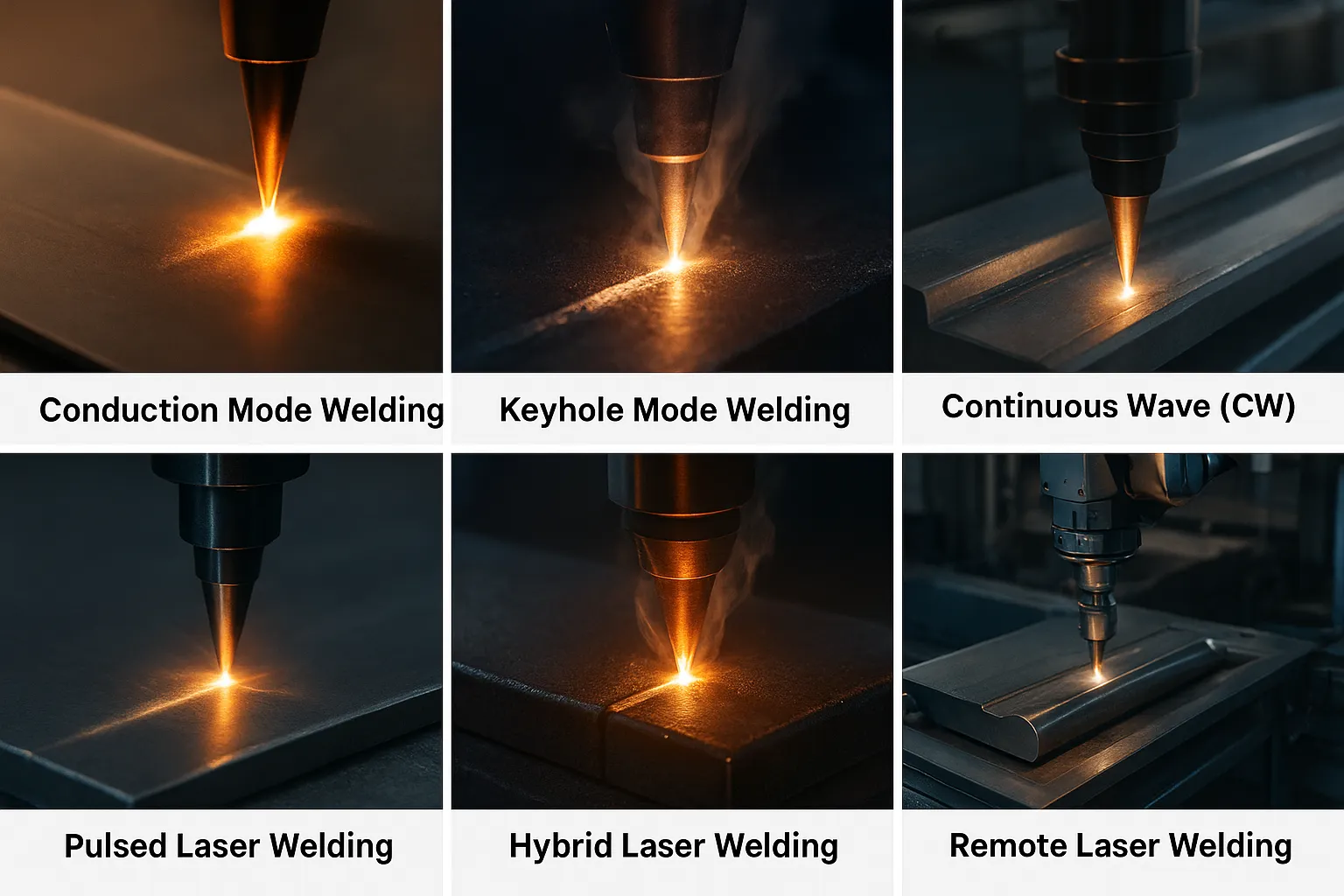

Laser welding can be performed using different techniques depending on the material type, thickness, and desired weld characteristics. The two most common methods are conduction mode welding and keyhole mode welding, along with several advanced variations that serve specialized applications.

Conduction Mode Welding

This method is used when a smooth, shallow weld is desired. The laser energy is absorbed at the surface and conducted inward through heat transfer rather than deep penetration.

- Ideal for thin materials and aesthetic welds, such as electronics or jewelry

- Produces smooth, clean surfaces with minimal spatter

- Typically uses low power density (<10⁶ W/cm²)

- Less risk of keyhole formation or material evaporation

Keyhole Mode Welding

In this technique, the laser power density is high enough to vaporize the material, creating a small, deep cavity called a keyhole. This allows the laser to penetrate deeply and produce a strong, narrow weld

- Used for thicker materials requiring deep welds

- Provides high aspect ratio welds (deep and narrow)

- Power density typically >10⁶ W/cm²

- Requires precise control to avoid porosity or collapse of the keyhole

Continuous Wave (CW) Laser Welding

In CW welding, the laser emits a constant beam, delivering continuous energy throughout the weld. This ensures uniform penetration and is suitable for high-speed industrial operations.

- Commonly used in automated production lines

- Provides consistent weld quality across long seams

- Often applied with fiber lasers for metals like steel and aluminum

- Requires precise beam control to prevent overheating or distortion

Pulsed Laser Welding

Pulsed laser welding delivers energy in short bursts rather than continuously. This allows precise control of heat input and minimizes thermal distortion.

- Best suited for delicate or heat-sensitive components

- Reduces cracking in brittle materials

- Enables spot or micro welding applications

- Often used with Nd:YAG lasers for electronic or medical device welding

Hybrid Laser Welding

Hybrid welding combines a laser beam with another heat source, typically Gas Metal Arc Welding (GMAW) or TIG welding, to enhance weld penetration and bridge larger gaps.

- Merges the speed and precision of lasers with the filler capabilities of arc welding

- Allows for thicker material welding with fewer defects

- Offers better tolerance for joint misalignment

- Common in shipbuilding, pipeline, and heavy machinery manufacturing

Remote Laser Welding

This advanced method uses scanning mirrors or robotic arms to direct the laser beam across multiple joints without moving the workpiece.

- Enables high-speed, non-contact welding

- Ideal for mass production environments (like automotive)

- Minimizes downtime due to no mechanical repositioning

- Requires high-precision robotic control systems

What Are The Advantages of Laser Welding?

Laser welding offers numerous benefits over traditional welding techniques, making it a preferred choice for precision manufacturing and advanced fabrication. Its unique combination of speed, accuracy, and versatility enhances both productivity and weld quality across various industries.

- Unmatched Precision & Control: The focused laser beam allows welding with extremely high accuracy (tolerances often ±0.1mm or better) and precise control over heat input. This enables the welding of delicate components and intricate geometries impossible with other methods.

- High Welding Speed: Laser welding is significantly faster than traditional arc welding processes (TIG, MIG). Speeds can be 3 to 10 times faster, dramatically increasing productivity in high-volume manufacturing.

- Minimal Heat Input & Distortion: The concentrated energy input results in a very narrow Heat-Affected Zone (HAZ). This minimizes thermal distortion, warping, and residual stresses in the workpiece, preserving material properties near the weld and reducing or eliminating the need for costly post-weld straightening.

- Deep Penetration Capability: In keyhole mode, laser welding achieves deep penetration in a single pass (up to 25mm+ for steel), reducing the need for multiple passes or joint preparation common in arc welding.

- Excellent Weld Quality & Strength: Laser welds typically exhibit high strength, good fatigue resistance, and a fine-grained microstructure due to rapid solidification. The process produces clean, spatter-free welds with excellent cosmetic appearance.

- Non-Contact Process: The laser beam doesn’t physically touch the workpiece. This eliminates tool wear, mechanical forces on the part, and allows access to complex or confined spaces.

- High Automation Potential: Laser welding integrates seamlessly with robotics, CNC machines, scanners, and automated handling systems. This enables lights-out manufacturing, high repeatability, and consistent quality, ideal for mass production.

- Versatility: Capable of welding a wide range of materials (steels, aluminum, titanium, copper, nickel alloys, plastics) and thicknesses (from thin foils <0.1mm to thick plates >25mm).

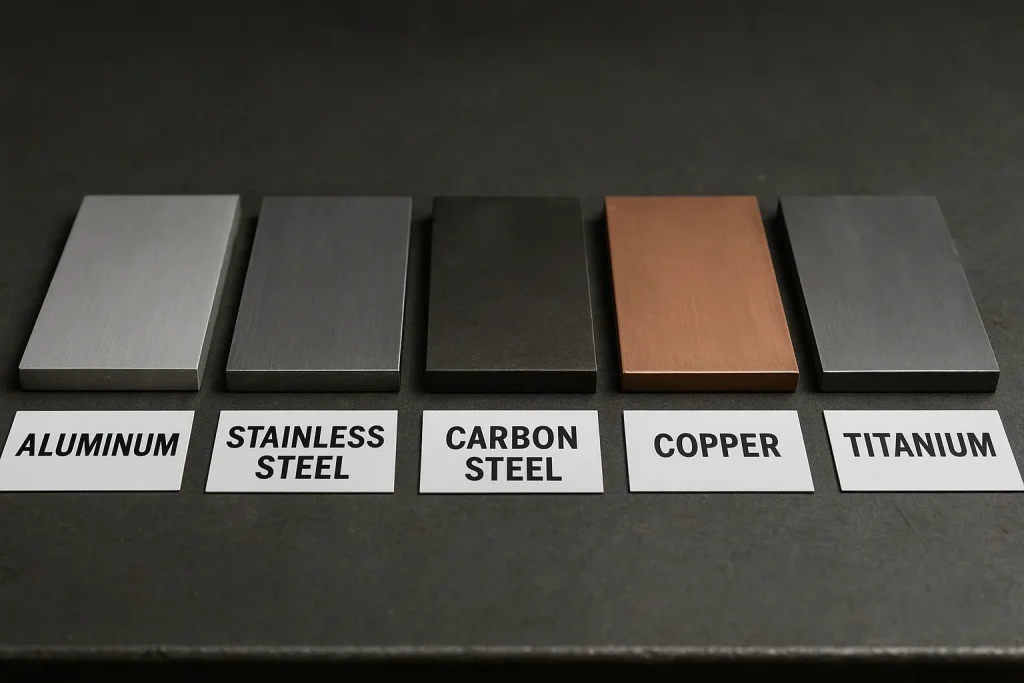

What Materials Are Used for Laser Welding?

Selecting the right materials is crucial for achieving strong joints, minimizing defects, and maintaining process efficiency in laser welding. Different metals respond uniquely to laser heat, conductivity, reflectivity, and cooling rates, meaning correct parameter settings and preparation are essential.

Aluminum

Using aluminum for laser welding presents some challenges due to its high reflectivity and thermal conductivity, but proper setups deliver strong and clean welds.

- Requires higher laser power and optimized focus

- Sensitive to porosity, shielding gas quality is critical

- Widely used in aerospace, electronics, and EV battery manufacturing

Stainless Steel

Stainless steel is one of the most commonly laser-welded metals thanks to its excellent weldability, corrosion resistance, and consistent results across industries.

- Good heat tolerance and low thermal distortion

- Produces clean, precise weld seams

- Ideal for food processing, medical devices, and automotive parts

Read more: Laser Welding Stainless Steel: Advantages, Grades, Parameters

Carbon Steel

Carbon steel welds well with most laser systems and offers strong mechanical properties, making it suitable for heavy-duty applications.

- Good absorption of laser energy

- Minimal porosity and cracking concerns

- Used extensively in automotive manufacturing and structural fabrication

Copper

Copper has very high reflectivity and heat conduction, so precision settings and powerful lasers (often fiber lasers) are necessary.

- Excellent for electrical and heat-transfer components

- High-power lasers reduce spatter and improve penetration

- Common in battery tabs, electronics, and electrical connectors

Titanium

Titanium is ideal for laser welding due to its strength-to-weight ratio and corrosion resistance, especially in high-performance environments.

- Requires inert shielding gas to avoid contamination

- Produces high-strength, lightweight welds

- Common in aerospace, medical implants, and high-end automotive parts

Applications of Laser Welding

Laser welding has a wide range of applications across various industries, including:

- Automotive: Laser welding is used to produce components for engines, transmissions, and body panels.

- Aerospace: Laser welding is used to produce components for aircraft engines, satellites, and rockets.

- Medical devices: Laser welding is used in the production of medical devices, such as implants, surgical instruments, and diagnostic equipment.

- Consumer electronics: Laser welding is used in the production of consumer electronics, such as smartphones, laptops, and tablets.

Laser Welding Safety

Although laser welding delivers exceptional precision and efficiency, it involves high-intensity beams and heat that require strict safety control. To ensure safe operation and protect personnel, manufacturers must follow essential safety protocols and proper equipment guidelines.

Read more: 8 common laser welding defects and how to fix them

Safety Protocols in Laser Welding

Since lasers are extremely powerful, strict safety protocols are necessary:

- Laser safety enclosures – prevent exposure to stray beams.

- Interlock systems – machines automatically shut down if the enclosure is opened.

- Ventilation – removes fumes and particles generated during welding.

Protective Equipment and Best Practices

Operators must use:

- Laser safety goggles (matched to the specific wavelength).

- Protective clothing against hot metal spatter.

- Training and certification to safely handle laser equipment.

Following ISO and ANSI laser safety standards is critical for workplace compliance.

Conclusion

Laser welding is one of the most advanced joining methods available today. Its precision, speed, and adaptability make it ideal for high-tech industries from automotive to aerospace. While the technology requires high investment and careful setup, the long-term advantages in quality and efficiency are undeniable. If you want to explore whether laser welding is the right solution for your application, consult with industry experts, request a demo, or contact us to dive deeper.

FAQs

Yes. Laser welding creates strong, high-quality joints through deep penetration and a concentrated heat source. In many cases, these joints are equal to or stronger than those from traditional welding, especially in precision components and high-strength metals.

Yes, most laser welding applications use shielding gas. Argon, helium, or nitrogen protects the molten pool from oxidation, reduces spatter, and improves weld quality. The gas type depends on the material and desired weld properties.

Laser welding has higher initial equipment costs than conventional methods but often offers lower long-term costs thanks to faster processing, minimal rework, low waste, and reduced labor. In production, the return on investment can be significant.