HVAC (Heating, Ventilation, and Air Conditioning) sheet metal fabrication is a critical process in building efficient and durable ductwork systems. From custom duct fabrication to precision cutting techniques, the quality of fabrication directly impacts airflow efficiency, energy consumption, and system longevity. In this article, we will explore the fabrication process, materials, and industry standards to ensure you get the best performance from your HVAC system.

What is HVAC Sheet Metal Fabrication?

HVAC sheet metal fabrication involves cutting, bending, welding, and assembling sheet metal to create ducts and components for HVAC systems. These components, such as ductwork, vents, housings, and enclosures, are essential for directing airflow, maintaining indoor air quality, and ensuring energy efficiency.

The process involves precise engineering to ensure a perfect fit within HVAC systems, optimizing performance while minimizing energy loss. High-quality fabrication helps reduce air leaks, improves system longevity, and enhances overall air distribution in residential, commercial, and industrial applications. HVAC sheet metal fabrication is the process of creating customized metal components used in heating, ventilation, and air conditioning (HVAC) systems. This includes ductwork, vents, housings, and enclosures, which are essential for directing airflow and maintaining system efficiency.

The HVAC Sheet Metal Fabrication Process: Step-by-Step

The fabrication process transforms raw sheet metal into precisely engineered ductwork components. Here’s a detailed breakdown:

Design and Planning

This step involves creating a detailed design of the ductwork system using specialized CAD/CAM software. The design must consider airflow requirements, building layout, pressure drops, and compliance with relevant building codes and industry standards (like SMACNA). Increasingly, Building Information Modeling (BIM) is used to integrate the ductwork design with the overall building model, improving coordination and minimizing clashes with other building systems.

Cutting

Once the design is finalized, the sheet metal is cut into the required shapes and sizes. Several methods are used:

- Shearing: A mechanical process using a shear to make straight cuts, suitable for simple shapes.

- Laser Cutting: A highly precise method using a focused laser beam to cut complex shapes and intricate patterns with minimal material waste.

- Plasma Cutting: A faster method that uses a high-temperature plasma arc to cut thicker materials.

- Waterjet Cutting: Uses a high-pressure stream of water mixed with an abrasive substance to cut materials that are sensitive to heat.

Bending and Forming

The cut pieces of sheet metal are then bent and formed into the desired shapes (such as rectangular ducts, round ducts, elbows, transitions).

- Press Brake Forming: Uses a press brake machine to create precise bends at specific angles.

- Roll Forming: Uses a series of rollers to create curves and cylindrical shapes. Proper consideration of material thickness and bend radius is crucial to prevent cracking or weakening the metal.

Welding and Joining

The formed pieces are joined together to create the ductwork components.

- MIG Welding (Gas Metal Arc Welding): A versatile and relatively fast welding process commonly used in HVAC fabrication.

- TIG Welding (Gas Tungsten Arc Welding): A more precise welding process, often used for thinner materials and critical joints.

- Spot Welding: A quick and efficient method for joining overlapping sheets of metal.

Other joining methods include riveting and using mechanical fasteners (such as screws, bolts).

Assembling

The individual components are assembled to create larger sections of ductwork. This often involves connecting straight sections, elbows, transitions, and other fittings. Proper sealing at all joints is critical to prevent air leakage.

Finishing

The final step involves finishing processes such as deburring (removing sharp edges), cleaning, and potentially applying a protective coating or paint, depending on the application and material. This ensures the ductwork is safe to handle and install and meets any required aesthetic or performance standards.

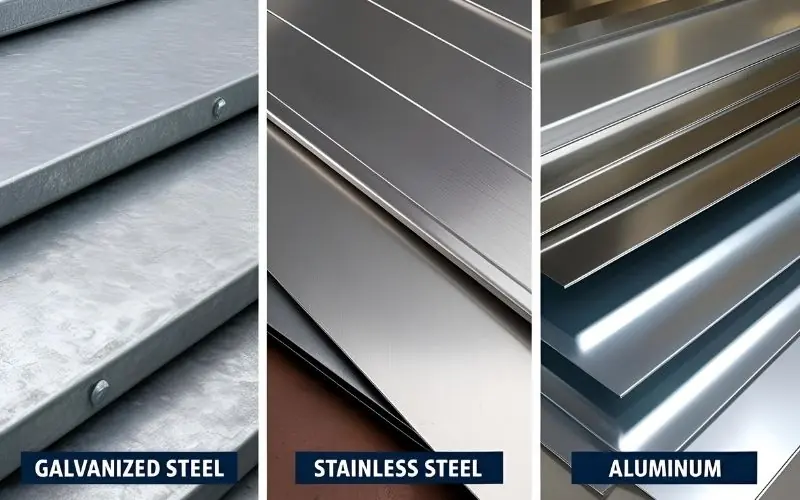

Common Materials Used in HVAC Sheet Metal Fabrication

The choice of material significantly impacts the performance, durability, and cost of HVAC ductwork. Here’s a breakdown of the most common materials:

Galvanized Steel

This is the workhorse of the HVAC industry. Galvanized steel is coated with zinc to protect it from rust and corrosion, making it a durable and cost-effective option. It’s available in various gauges (thicknesses), with thicker gauges used for larger ducts and higher pressure systems.

Stainless Steel

Stainless steel offers superior corrosion resistance, making it ideal for applications where exposure to moisture, chemicals, or harsh environments is a concern (such as laboratories, hospitals, and industrial kitchens). While more expensive than galvanized steel, its longevity often justifies the higher initial cost.

Aluminum

Aluminum is lightweight and naturally corrosion-resistant. Its lighter weight makes it easier to install, especially in situations where weight is a critical factor. It’s also a good choice for outdoor applications.

Black Iron

Black iron (uncoated steel) is primarily used for kitchen exhaust systems due to its ability to withstand high temperatures and grease buildup. It requires proper cleaning and maintenance to prevent corrosion.

Other Materials

Occasionally, specialized materials like fiberglass duct board or flexible ducting may be used in specific situations, but sheet metal remains the primary choice for most HVAC ductwork.

| Galvanized Steel | Stainless Steel | Aluminum | Black Iron | |

| Corrosion Resistance | High | Very high | High | Low |

| Strength | High | Very high | Moderate | High |

| Cost | Moderate | High | Moderate | Moderate |

| Applications | General HVAC ductwork, residential, and commercial buildings | Corrosive environments, hospitals, and laboratories | Lightweight applications, outdoor installations | Kitchen exhaust systems |

| Advantages | Durable, cost-effective, readily available | Extremely durable, resists corrosion, long lifespan | Lightweight, corrosion-resistant, easy to install | Withstands high temperatures, durable |

| Disadvantages | Can corrode in highly corrosive environments | More expensive than galvanized steel | Lower strength than steel, may require thicker gauges for larger ducts | Susceptible to corrosion without proper maintenance and cleaning |

Advantages of Quality HVAC Sheet Metal Fabrication

The seemingly simple ductwork hidden within your walls and ceilings plays a surprisingly significant role in your building’s performance and your well-being. High-quality fabrication translates directly into tangible benefits:

Energy Efficiency

A well-fabricated duct system minimizes air leakage, a major source of energy waste. Think of it like this: a poorly sealed duct system can lose up to 30% of its conditioned air, forcing your HVAC system to work harder and consume more energy. Precision fabrication, tight seams, and proper sealing ensure that the air you pay to heat or cool reaches its intended destination, reducing your energy bills and your carbon footprint.

Improved Indoor Air Quality (IAQ)

Proper fabrication prevents dust, debris, and other contaminants from entering the ductwork and circulating throughout your building. Leaky ducts can draw in unfiltered air from attics, crawl spaces, or other areas, potentially introducing allergens, pollutants, and even mold spores into your living or working environment. High-quality fabrication, combined with proper filtration, helps maintain a clean and healthy indoor environment.

System Longevity and Durability

High-quality materials and fabrication techniques extend the lifespan of your entire HVAC system. Durable ductwork resists corrosion, damage, and degradation, reducing the need for costly repairs and replacements. This translates to long-term cost savings and peace of mind.

Noise Reduction

Poorly designed or fabricated ductwork can be a significant source of noise pollution. Rattling, vibrations, and air turbulence can create distracting and uncomfortable sounds. Well-fabricated ducts, with smooth transitions and properly sized components, minimize noise and contribute to a quieter environment.

Optimal Airflow and Comfort

Consistent temperature and airflow throughout a building are hallmarks of a well-designed and fabricated HVAC system. Proper fabrication ensures that air is distributed evenly, eliminating hot and cold spots and creating a comfortable environment for occupants.

Quality Control and Standards in HVAC Sheet Metal Fabrication

Rigorous quality control is paramount to ensure that the fabricated ductwork meets the required performance standards and contributes to a healthy and efficient HVAC system.

Importance of Quality Control

Defective ductwork can lead to significant problems, including energy waste, poor indoor air quality, reduced system performance, and even structural issues. Thorough quality control checks throughout the fabrication process are essential to prevent these issues.

Key Quality Control Checks

To ensure the durability, performance, and compliance of fabricated ductwork, rigorous quality control checks are conducted throughout the manufacturing process. These checks focus on key aspects such as dimensional accuracy, leakage prevention, material integrity, and weld quality.

- Dimensional Accuracy: Precise measurements are verified throughout the process to ensure that the ductwork components fit together correctly and meet the design specifications. This is typically done using calibrated measuring tools, and increasingly, with automated inspection systems.

- Leakage Testing: Ductwork is tested for air leakage using various methods, such as pressure testing. This involves sealing off sections of the ductwork and applying a controlled pressure, then measuring any pressure drop over time. Lower leakage rates indicate better fabrication quality.

- Material Inspection: Incoming sheet metal is inspected for defects, such as scratches, dents, or inconsistencies in thickness. This ensures that only high-quality materials are used in the fabrication process.

- Weld Quality Inspection: Welds are inspected visually for defects like cracks, porosity, or incomplete fusion. Non-destructive testing methods, such as ultrasonic testing or radiography, may be used for critical welds.

Relevant Industry Standards

Following the industry standards is essential when designing and installing HVAC duct systems to ensure safety, efficiency, and compliance. Several key organizations set these standards, including SMACNA, ASHRAE, and local building codes.

- SMACNA Standards: The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) publishes comprehensive standards for HVAC duct construction, covering materials, fabrication techniques, and installation practices. These standards are widely recognized and followed in the industry.

- ASHRAE Standards: The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) also publishes standards related to HVAC systems, including standards for indoor air quality and energy efficiency

- Local Building Codes: Fabricated ductwork must also comply with local building codes, which may have specific requirements for materials, fire resistance, and installation.

Future Trends in HVAC Sheet Metal Fabrication

The HVAC sheet metal fabrication industry is constantly evolving, driven by technological advancements and a growing focus on efficiency and sustainability.

Automation and Robotics

The use of robots for welding, cutting, and assembly is increasing, leading to greater precision, efficiency, and improved worker safety. Robotic systems can perform repetitive tasks with consistent accuracy, reducing errors and increasing productivity.

Advanced Software and BIM Integration

Building Information Modeling (BIM) is becoming increasingly integrated into the fabrication process. BIM allows for the creation of detailed 3D models of the entire building, including the HVAC system. This improves coordination between different trades, reduces clashes, and optimizes the design and fabrication of the ductwork.

Sustainable Materials and Practices

There’s a growing demand for eco-friendly materials, such as recycled steel and aluminum. Fabricators are also adopting more sustainable practices, such as minimizing material waste, reducing energy consumption, and using water-based cleaning solutions.

Prefabrication and Modular Construction

Prefabricated ductwork components being off-site in a controlled environment is becoming more common. This allows for faster and more efficient installation on the job site, reducing labor costs and minimizing disruption.

3D Printing (Additive Manufacturing)

While still in its early stages, 3D printing has the potential to revolutionize sheet metal fabrication. It could be used to create complex ductwork components with intricate geometries that would be difficult or impossible to fabricate using traditional methods.

Conclusion

HVAC sheet metal fabrication is a critical component of any well-functioning HVAC system. Understanding the processes, materials, and quality control standards involved is essential for ensuring energy efficiency, optimal indoor air quality, and system longevity. By choosing a qualified and experienced fabricator who embraces best practices and utilizes the latest technologies, you can ensure that your HVAC system performs at its best, providing comfort and a healthy environment for years to come.

FAQs

Galvanized steel is the most commonly used sheet metal for HVAC systems due to its durability, corrosion resistance, and ease of fabrication. Other materials include aluminum for its lightweight properties and stainless steel for high-humidity or corrosive environments.

The HVAC fabrication process begins with detailed design using CAD or BIM software. The sheet metal is then cut using tools such as shears, plasma cutters, or lasers. Next, the metal is bent and formed into shape using equipment like press brakes. The formed pieces are then assembled through welding, riveting, or fastening. Finally, the components are cleaned, sealed, and sometimes coated to ensure durability and performance before installation.

Standards from SMACNA and ASHRAE guide duct construction, airflow, and air quality, while local building codes also apply to ensure fire safety, proper insulation, and the use of appropriate materials