Laser welding aluminum promises fast, clean, and precise joints, but achieving strong, defect-free welds isn’t as simple as pointing a laser at the metal. Between high reflectivity, heat-conductivity challenges, and crack-sensitive alloys, even experienced welders struggle to get consistent results. This guide breaks down proven techniques, process parameters, and expert troubleshooting to help you weld aluminum with confidence and production-quality results. Continue reading to master the essentials and avoid costly trial-and-error mistakes.

Why Choose Laser Welding Aluminum?

Laser welding aluminum is a key process in automotive, aerospace, and electronics manufacturing thanks to its precision, speed, and ability to create clean, high-strength joints with minimal heat distortion. The focused fiber laser beam delivers high energy density, enabling deep penetration and fast welding of thin aluminum parts such as battery trays, aircraft panels, and electronic housings, while ensuring excellent accuracy and surface quality.

Compared with MIG or TIG methods, laser welding creates a smaller heat-affected zone (HAZ), cuts post-processing, and integrates smoothly with automated systems. It’s a cost-efficient, energy-saving, and high-precision solution that supports modern manufacturing of lightweight, durable, and visually flawless aluminum components.

How To Laser Weld Aluminum?

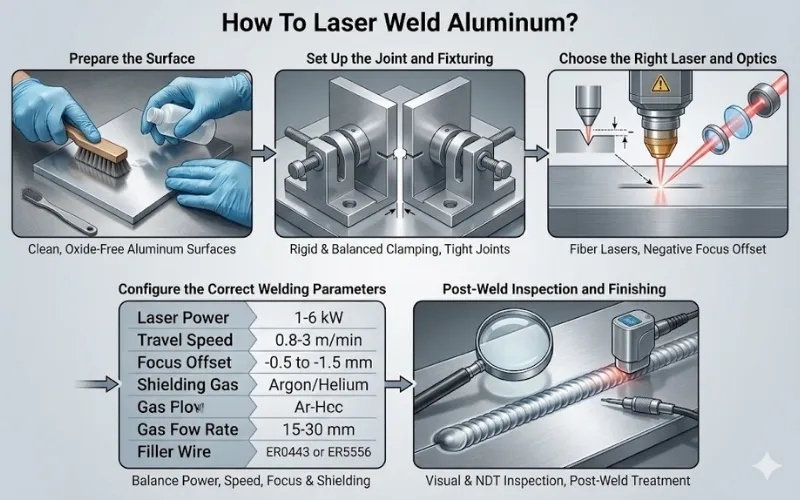

Successful aluminum laser welding depends on precision at every stage, from preparation to quality control. Below is a step-by-step guide outlining the key stages of the process and the technical reasoning behind each one.

Prepare the Surface

Clean, oxide-free aluminum surfaces are the foundation of a successful laser weld. Even microscopic contamination can trap hydrogen, resulting in porosity or poor fusion.

- Start by degreasing with acetone or ethanol to remove oil, grease, or coolant residues. Never use chlorinated solvents; they can produce toxic vapors.

- Mechanically clean with a dedicated stainless-steel brush or non-abrasive pad to strip off the aluminum oxide film.

- For critical components (such as aerospace or electronic parts), apply chemical etching or ultrasonic cleaning for thorough decontamination.

- Perform welding within 1–2 hours after cleaning, as the oxide layer reforms quickly when exposed to air.

- Store pre-cleaned parts in a dry, sealed environment if immediate welding isn’t possible.

And you must remember this: Hydrogen is highly soluble in molten aluminum but not in its solid form – any moisture, even an invisible film, can create porosity as the weld cools.

Set Up the Joint and Fixturing

Because aluminum expands and contracts significantly when heated, precision fixturing and joint design are key to controlling distortion and ensuring dimensional accuracy.

- Keep joint gaps below 0.15-0.2 mm; even a slightly open seam can lead to incomplete fusion.

- Use rigid but balanced clamping – tight enough to prevent movement, but not so rigid that it induces stress during cooling.

- Preheat thick plates (80-150°C) to reduce temperature gradients and prevent cracking, especially for 6xxx series alloys.

- Verify that joint edges are smooth and parallel, and that laser alignment is consistent across the weld path.

- Incorporate heat sinks or backing bars when welding thin or delicate parts to absorb excess heat.

Tip: During production runs, monitor fixture wear and thermal drift. Even small alignment changes can shift focus and degrade weld penetration.

Choose the Right Laser and Optics

The choice of laser and optical configuration determines how effectively energy is transferred to the aluminum surface.

- Fiber lasers (1-6 kW) are ideal for aluminum due to their high beam quality and energy efficiency.

- Use a slight negative focus offset (-0.5 to -1.5 mm) to concentrate energy below the surface, promoting stable keyhole formation.

- Adjust spot size (0.2-0.6 mm) and beam mode based on part thickness and joint design, smaller spots for thin sheets, larger for deeper penetration.

- Install protective windows or back-reflection sensors, as aluminum reflects up to 90% of infrared light; this prevents optical damage.

- Regularly cleaning optics and inspecting the beam path, dust or residue can reduce power density and alter the beam profile.

In automated setups, maintaining consistent focus and beam alignment is more critical than raw power. A perfectly aligned 3 kW beam can outperform a poorly tuned 5 kW system.

Configure the Correct Welding Parameters

The right balance of power, speed, focus, and shielding defines weld quality.

| Parameter | Recommended Range | Practical Notes |

| Laser Power | 1-6 kW | Higher for thick plates (>3 mm) |

| Travel Speed | 0.8-3 m/min (30-120 in/min) | Balance depth and bead width |

| Focus Offset | -0.5 to -1.5 mm | Improves penetration and reduces porosity |

| Shielding Gas | Argon, Helium, or Ar-He Mix | Helium increases absorption and fluidity |

| Gas Flow Rate | 15-30 L/min | Maintain laminar flow |

| Filler Wire | ER4043 or ER5356 | Prevents hot cracking in 6xxx alloys |

Additional tuning considerations

- Begin with a short tack weld to stabilize thermal conditions before the main run.

- For 6xxx and 7xxx alloys, consider a pre-pulse or ramp-up mode to minimize cracking at the start.

- Keep consistent standoff distance and stable shielding coverage throughout the weld path.

Note: A helium-rich (50-75%) gas mix can raise heat absorption by up to 25%, improving penetration and bead smoothness.

Post-Weld Inspection and Finishing

Quality verification ensures structural integrity and aesthetic standards are met.

- Inspect welds visually for uniform bead shape, smooth transition, and absence of porosity or undercut.

- For structural parts, perform non-destructive testing (NDT) using methods such as ultrasonic, X-ray, or dye-penetrant inspection.

- Conduct mechanical tests (tensile, bend, and hardness) for critical joints.

- Remove discoloration or oxide by light brushing or alkaline cleaning if required.

- Apply anodizing, coating, or corrosion protection for outdoor or marine environments.

- Store finished components in low-humidity conditions to preserve surface integrity.

Our reminder: Avoid aggressive grinding or polishing; aluminum’s softness can smear over fine cracks, hiding defects during inspection.

Why Is Aluminum Challenging To Laser Weld?

Laser welding aluminum requires a deep understanding of its physical and metallurgical behavior. Unlike steel or stainless steel, aluminum responds differently to heat and light, which creates several process challenges that directly impact weld quality and repeatability. Below are the key difficulties and what every engineer or fabricator should know to overcome them.

Read more: Laser Welding Stainless Steel: Advantages, Grades, Parameters

High Thermal Conductivity

Aluminum conducts heat approximately four to five times faster than steel, which causes the molten pool to cool and solidify rapidly. This makes it difficult to maintain stable penetration, especially at the start of the weld.

What this means during welding:

- The weld pool tends to freeze before full penetration is achieved, increasing the risk of lack-of-fusion defects.

- Higher laser power or slower travel speed is needed to maintain sufficient heat input.

- Uneven heat distribution can lead to distortion in thin sheets or poor consistency across thick joints.

How to manage it:

- Use preheating (80-150°C) for thicker sections.

- Employ multi-pass or oscillating beam techniques to stabilize the weld pool.

- Choose helium or helium-argon gas mixtures to increase heat transfer efficiency.

High Reflectivity at Laser Wavelengths

Aluminum reflects over 90% of infrared laser light (1,064 nm wavelength typical of fiber and NdYAG lasers). This means a large portion of the laser energy is initially reflected rather than absorbed, especially on untreated or polished surfaces.

Challenges caused by reflectivity:

- Inefficient energy coupling during initial melting.

- Risk of back-reflection damaging expensive laser optics.

- Inconsistent keyhole formation leading to unstable penetration.

How to reduce reflectivity:

- Mechanically roughen or bead-blast the surface before welding.

- Use higher initial power spikes or pulse shaping to quickly form a stable keyhole.

- Maintain clean optics and angled beam entry (5-10°) to prevent direct back-reflection.

Surface Oxide Layer

Aluminum’s natural oxide film (Al₂O₃) forms instantly when exposed to air. While it protects against corrosion, it has a melting point around 2,050°C, much higher than aluminum’s 660°C base metal – creating a barrier to fusion.

Problems it causes:

- Traps gases, leading to porosity in the weld.

- Causes lack of fusion and irregular keyhole behavior.

- Increases spatter and unstable arc or laser interaction.

Prevention techniques:

- Clean surfaces thoroughly with stainless-steel brushes or alkaline etchants.

- Wipe with acetone or ethanol before welding to remove oils.

- Weld immediately after cleaning to minimize oxide reformation.

Alloy Crack Sensitivity

Many aluminum alloys, particularly 6xxx and 7xxx series, are prone to hot cracking during solidification because of their alloying elements (Si, Mg, and Zn). Rapid solidification in laser welding magnifies this risk.

Why does it happen:

- The narrow molten zone solidifies quickly, trapping impurities and gases.

- Alloying elements form low-melting eutectic phases at grain boundaries.

- Residual stresses from fast cooling increase crack propagation.

Solutions to minimize cracking:

- Use filler wires (ER4043 or ER5356) to balance composition and reduce crack susceptibility.

- Preheat the workpiece to relieve thermal gradients.

- Consider hybrid laser-arc welding, which introduces filler and improves wetting.

Porosity Formation

Porosity is one of the most common defects in laser-welded aluminum. It occurs when hydrogen gas becomes trapped during rapid solidification.

Causes of porosity:

- Moisture or oil contamination on surfaces or wire.

- Inadequate shielding gas coverage.

- Keyhole instability caused by power fluctuations or poor focus.

How to prevent it:

- Use dry, high-purity shielding gas (Argon or Helium).

- Maintain consistent gas flow (15-30 L/min) with proper nozzle angle.

- Store filler wire in sealed, humidity-controlled environments.

- Implement real-time keyhole monitoring in automated setups.

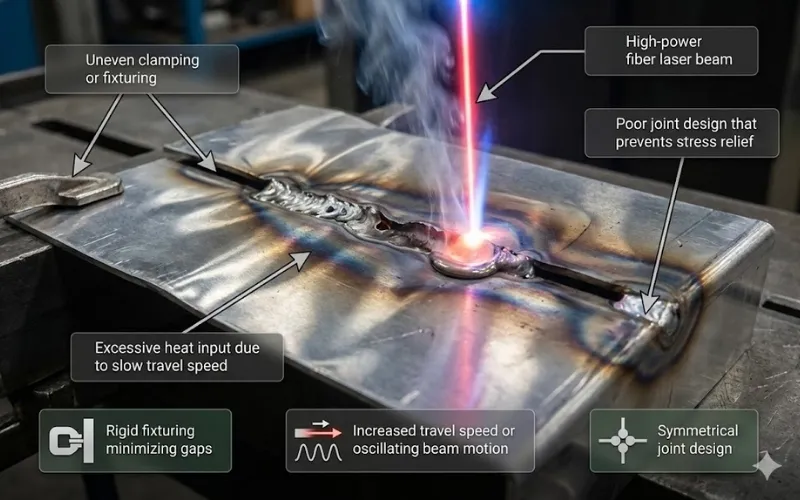

Distortion and Residual Stress

Even with low heat input, the uneven heating and cooling of aluminum can produce distortion – particularly in thin-walled components.

Factors contributing to distortion:

- Uneven clamping or fixturing.

- Excessive heat input due to slow travel speed.

- Poor joint design that doesn’t allow stress relief.

Prevention measures:

- Use rigid fixturing and minimize restraint gaps.

- Increase travel speed or use beam oscillation to distribute heat.

- Optimize joint design with symmetrical geometry when possible.

What Are The Advantages of Laser Welding Aluminum?

Laser welding aluminum combines speed, precision, and efficiency, making it one of the most advanced joining methods in modern manufacturing. Compared to MIG or TIG welding, it delivers cleaner seams, tighter tolerances, and minimal post-processing, which are ideal for industries demanding lightweight, high-strength, and visually flawless components. Here are the key advantages that make laser welding aluminum a superior choice

- Exceptional precision and low distortion: The focused beam allows narrow, accurate welds with limited heat spread, reducing deformation even in thin sections.

- High welding speed and efficiency: operates up to 3-10x faster than arc welding, supporting automated production and lower cycle times.

- Clean, aesthetic welds: produce smooth, oxide-free seams that often require no polishing or grinding.

- Strong and Reliable joints: optimized parameters create deep, consistent penetration with minimal porosity and strong tensile properties.

- Automation-friendly: easily integrated into robotic or CNC systems for high precision, repeatability, and real-time monitoring.

- Lower consumables and maintenance: no electrodes and less filler mean reduced operating costs and downtime

- Eco and operator-friendly: lower energy use and minimal fumes make it a cleaner, safer, and more sustainable process.-focus and wobble heads for better gap-bridging and surface finish.

Conclusion

Laser welding aluminum offers a unique combination of precision, strength, and efficiency when the process is properly controlled from preparation to inspection. By understanding the metal’s characteristics, such as its high reflectivity, thermal conductivity, and sensitivity to contamination, manufacturers can achieve clean and durable welds with consistent quality. This technology has become an essential solution for producing lightweight, high-performance components across industries, including automotive, aerospace, and electronics, proving its value in modern manufacturing.

FAQs

Yes, it is. When parameters and filler are correct, laser-welded aluminum joints are as strong or stronger than MIG/TIG in many cases.

Yes for 1xxx, 3xxx, 5xxx series and tight fit-ups. But for 6xxx, filler is strongly recommended.