Fiber laser welding is rapidly becoming the go-to solution for manufacturers who demand speed, precision, and clean welds without extensive rework. Yet many engineers and fabricators still struggle with choosing the right setup, optimizing parameters, and understanding where fiber laser welding truly outperforms traditional methods. This guide breaks everything down clearly, from benefits, applications to materials, equipment, and expert considerations so you can make confident decisions and achieve stronger, cleaner, and more efficient welds. Let’s explore how to get the most out of this powerful technology.

What is Fiber Laser Welding?

Fiber laser welding is an advanced precision welding technology that uses a high-intensity focused laser beam delivered through fiber-optic cables to fuse metal parts with outstanding accuracy. Energy from a fiber laser source is guided through flexible fibers to create deep penetration welds, a minimal heat-affected zone (HAZ), and strong joints (even on thin metals and complex geometries). Easily integrated with robotic welding and CNC automation, it supports high-speed industrial manufacturing in industries like automotive, battery production, and medical devices, while delivering superior weld quality, efficiency, and process control.

Read more: Laser welding guide: Process, methods, advantages

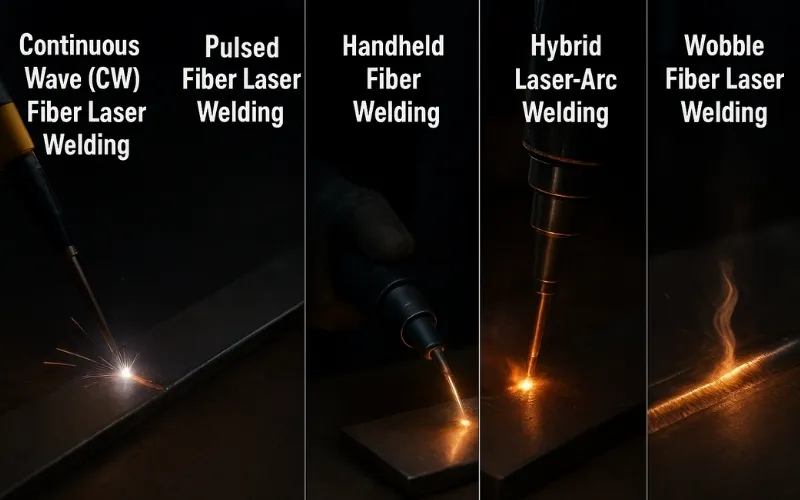

Types of Fiber Laser Welding

Fiber laser welding can be performed in several modes depending on the thickness of the material, required weld quality, and production needs. Understanding each type helps manufacturers choose the right method for productivity, cost efficiency, and weld strength.

Continuous Wave (CW) Fiber Laser Welding

CW welding emits a constant, uninterrupted laser beam, creating deep and uniform penetration.

Best For

- Medium to thick metals

- Long, continuous weld seams

- High-speed automated production lines

Common Applications

- Automotive body and battery modules

- Aerospace components

- Industrial machinery frames

Benefits

- Stable weld quality at high speeds

- Deep penetration (ideal for structural joints)

- Compatible with automation and robotics

Note: CW welding is preferred for EV battery packs and precision automotive components where consistency and fatigue strength are critical.

Pulsed Fiber Laser Welding

The laser outputs energy in pulses, allowing the metal to cool between bursts – ideal for delicate or heat-sensitive components.

Best For

- Thin metals (<1.5mm)

- Jewelry and watch components

- Medical devices and electronics

When to Choose

- You need microscopic accuracy

- The material is ultra-thin or prone to distortion

- Cosmetic finish matters

Advantages

- Minimal heat distortion

- Precise control over the weld pool

- Very clean, aesthetic results

Tip: Use pulsed mode for stainless steel kitchenware parts and fine battery tabs where appearance and thermal control matter.

Handheld Fiber Laser Welding

A portable welding system is replacing MIG/TIG in many workshops due to its speed and ease of use.

Ideal For

- Sheet metal fabrication shops

- Stainless steel furniture & decorative panels

- Repair & field welding

Features

- High mobility and ease of operation

- Seam finishing is often not required

- Capable of welding dissimilar metals (with proper settings)

Use Case Examples

- Elevator panels

- Stainless steel sink production

- Metal doors, frames, and cabinets

Note: Many fabricators cut polishing labor by 60–80% after switching from TIG to handheld fiber welding.

Hybrid Laser-Arc Welding

Combines fiber laser and arc welding (like MIG/GMAW) in one process.

Purpose

- Overcome the limitations of traditional arc welding in thick steel

- Improve penetration and weld quality on challenging joints

Best For

- Structural steel

- Shipbuilding

- Pipeline welding

- Heavy equipment frames

Advantages

- High penetration with strong weld strength

- Better gap-bridging than laser alone

- Faster than conventional arc welding

Use Tip: Ideal when your application demands fast, deep-penetration welding on thick material where a fiber laser alone isn’t sufficient.

Wobble Laser Welding (Beam Oscillation Welding)

A more advanced technique where the laser beam oscillates in a controlled pattern (circle, zig-zag, figure-8).

Why It Matters

- Improves seam uniformity

- Enhances gap tolerance

- Reduces porosity and cracks

- Creates wider, stronger, cosmetic seams

Industries Using It

- Stainless steel furniture

- Automotive components

- Food-grade equipment fabrication

Operator insight: Wobble heads are extremely valuable when welding corner joints, ornamental stainless steel, and visible seams that need a polished appearance.

Advantages of Fiber Laser Welding

Fiber laser welding stands out for its speed, accuracy, and process control, especially compared to TIG, MIG, or CO₂ lasers.

Speed and Precision

The combination of high speed and superior precision is perhaps the single greatest economic driver for adopting fiber laser welding over conventional methods.

- Welding speeds up to 4x faster than TIG/MIG

- Micro-level beam control for high-precision seams

- Minimal distortion due to narrow heat-affected zone (HAZ)

This makes it ideal for industries requiring tight tolerances and cosmetic weld quality.

Versatility in Materials

Fiber lasers can weld:

- Stainless steel

- Carbon steel

- Aluminum and alloys

- Copper (with proper tuning)

- Titanium

They handle thin sheets and medium-thickness metal with excellent consistency.

Cost-Effectiveness

Although initial investment is higher, fiber laser welding delivers cost savings through:

- Reduced rework and polishing

- Less consumable use (no filler wire required in many cases)

- Lower energy consumption

- Faster production cycles

- Longer machine lifespan with low downtime

Many manufacturers see rapid ROI after switching from TIG/MIG processes.

Key Parameters in Fiber Laser Welding

Correct settings are critical to achieving optimal weld results. Professionals adjust parameters based on metal type, thickness, and seam design.

Power Settings

Laser power ranges from 1000W to 6000W+, depending on application:

- 1000-1500W: thin stainless sheets, furniture

- 2000-3000W: general fabrication, automotive

- 4000W+: thick metal welding, industrial automation

Higher power increases penetration but requires proper heat management.

Speed and Feed Rates

Selecting the right welding speed and laser power is crucial to achieving strong, clean, and consistent weld quality in fiber laser welding. The table below provides recommended speed and power ranges for different materials and thicknesses, based on practical industrial experience and real-world manufacturing standards.

| Material | Thickness (mm) | Recommended Welding Speed (m/min) | Suggested Laser Power (kW) | Notes |

| Stainless Steel | 0.5 | 40-60 | 1-1.5 | High-speed, clean edges; N2/He recommended for surface finish |

| 1.0 | 20-40 | 1.5-2.5 | Suitable for continuous or handheld welding | |

| 2.0 | 8-20 | 2-3 | Wobble function improves seam quality | |

| Aluminum | 1.0 | 8-18 | 2-3 | Heat-sensitive; He or mixed gas preferred |

| 2.0 | 4-10 | 3-4 | Requires stable arc control | |

| Mild Steel (Carbon Steel) | 1.0 | 25-45 | 1-2 | Very fast welding, low spatter |

| 2.0 | 10-25 | 2-3 | Smooth finish, easy to weld | |

| 3.0 | 6-15 | 3-4.5 | Ideal for robotic/automated welding | |

| Copper | 0.8 | 5-12 | 3-6 (Yb-fiber laser) | Best results with 1µm laser; high power needed |

| 1.5 | 3-8 | 6-8 (blue laser optimal) | Blue laser has higher absorption + smoother seam |

Focus and Beam Quality

The beam must be precisely focused to:

- Concentrate energy at the joint

- Achieve deep penetration

- Maintain narrow HAZ

- Produce clean, consistent seams

Modern systems use auto-focus and wobble heads for better gap-bridging and surface finish.

Conclusion

Fiber laser welding is reshaping the future of precision metal fabrication thanks to its speed, cleanliness, automation capability, and exceptional weld quality. With proper machine selection, operator training, and safety controls, manufacturers benefit from robust performance and rapid ROI. Whether you’re evaluating technology investments or upgrading your fabrication process, fiber laser welding provides a future-proof pathway to higher productivity and competitive advantage.

FAQs

Yes. Fiber laser welds offer deep penetration and high metallurgical strength, often matching or exceeding the base metal when parameters are optimized.

Yes. Shielding gas is used to prevent oxidation and improve weld quality. Common gases include argon, nitrogen, and helium, depending on the material type.