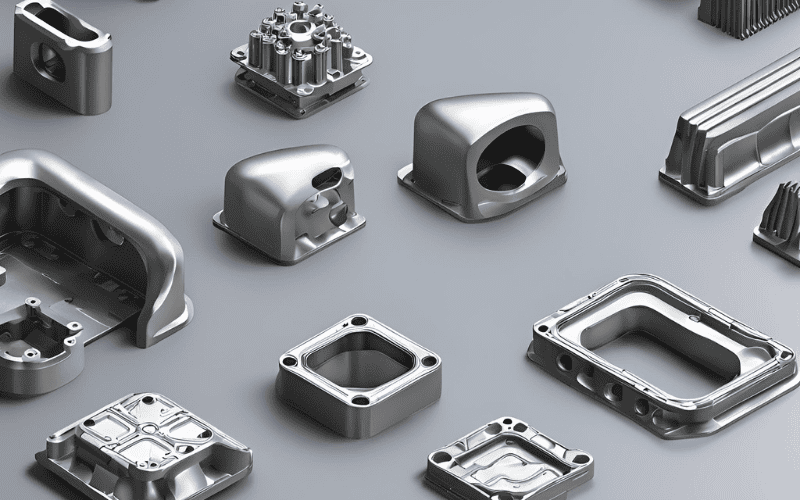

Die casting is one of the most widely used manufacturing processes in the modern industrial world. It plays a key role in industries like automotive, aerospace, consumer electronics, and many others because it enables the production of complex metal shapes with remarkable precision and cost efficiency. This article offers a detailed look at die casting, covering everything from its process, types, and materials to its advantages, disadvantages, and practical applications. It also emphasizes the process’s significance in creating sustainable and lightweight constructions.

What is Die Casting?

Die casting is a metal casting process where molten metal, such as zinc, aluminum, or magnesium, is injected into a precision-engineered mold cavity, or die, at high pressure. These molds are crafted to produce intricate designs with outstanding dimensional accuracy and smooth surface finishes. Thermal conductivity and mold material selection are vital in ensuring the process’s repeatability and production efficiency.

Unlike other casting methods, die casting offers superior quality, consistent output, and minimal need for post-processing. It is widely used in automotive and aerospace industries for lightweight components, in electronics for intricate parts, and in consumer goods for products requiring aesthetic finishes. Additionally, the process has gained attention for its recycling potential, making it an environmentally sustainable option.

The Casting Process

Die casting involves a series of carefully controlled steps to ensure the production of high-quality parts. Here are some key steps:

Metal Melting

Firstly, the chosen metal alloy, often aluminum, zinc, or magnesium, is melted in a furnace. Precise temperature control is critical, as it directly influences the metal’s flow characteristics and the final product’s quality. For aluminum alloys, temperatures typically range from 660°C to 760°C (1220°F to 1400°F).

Mold Preparation

The die, typically made of hardened tool steel, is prepped by cleaning and applying a lubricant. The lubricant aids in the smooth flow of molten metal, facilitates part release, and prolongs die life. Die design is a crucial aspect, influencing the final product’s integrity and the efficiency of the casting process.

Metal Injection

The machine injects molten metal into the die cavity at high speed and pressure, typically between 1,500 and 25,000 psi. Two primary methods exist: hot chamber and cold chamber die casting. Hot chamber machines, commonly used for zinc, tin, and lead alloys, have the injection system submerged in the molten metal. Cold chamber machines, suited for aluminum, magnesium, and copper alloys, require ladling molten metal into the injection sleeve. The choice between a hot and cold chamber depends on the metal’s characteristics and desired production rate.

Cooling and Solidification

The molten metal rapidly cools and solidifies within the die, taking the shape of the cavity. The cooling rate significantly affects the microstructure and mechanical properties of the casting. Controlled cooling is essential to prevent defects like porosity and shrinkage.

Casting Removal

After solidification, the die opens, and the casting is ejected using ejector pins. Modern machinery automates this step, enhancing efficiency.

Trimming and Finishing

Finally, excess material from the casting, such as flash or runners, is trimmed. Depending on the final product’s requirements, finishing processes like deburring, machining, surface treatments (painting, powder coating), or plating might be applied.

Types of Die Casting Methods

There are two main types of die casting: hot chamber and cold chamber. Different types of die-casting methods are used depending on the material, application, and production requirements.

| Feature | Hot Chamber | Cold Chamber |

| Metal Used | Low-melting-point alloys such as zinc or magnesium | Higher-melting-point alloys such as aluminum or copper |

| Process | Metal is melted in a crucible attached to the machine and injected directly. | Molten metal is ladled into a separate chamber and then injected. |

| Cycle Time | Faster | Slower |

| Cost | Generally lower tooling costs | Higher tooling costs |

Materials Used in Die Casting

The choice of metal or alloy is crucial in die casting, as it directly impacts the properties and performance of the finished part. Here are some of the most commonly used materials:

Aluminum Alloys

Aluminum alloys are extremely popular in die casting due to their excellent combination of properties (lightweight, high strength-to-weight ratio, excellent corrosion resistance, good thermal and electrical conductivity, and good dimensional stability). Some common alloys of aluminum:

- A380: The most widely used aluminum die-casting alloy. Offers a good balance of casting, mechanical, and thermal properties.

- A383: Similar to A380 but with improved die-filling characteristics.

- A360: Offers higher corrosion resistance and better ductility than A380.

Zinc Alloys

Zinc alloys are known for their excellent casting characteristics and ability to produce parts with very fine details and thin walls. It has a low melting point, excellent fluidity (allowing for intricate shapes), good dimensional accuracy, high impact strength, and good plating and finishing characteristics. Some common alloys:

- Zamak 3: The most widely used zinc die-casting alloy. Offers a good balance of properties and cost-effectiveness. (Zamak 3 Alloy Datasheet)

- Zamak 5: Higher strength and hardness than Zamak 3, due to a higher copper content.

- ZA-8: Offers higher strength and creep resistance than Zamak alloys.

Magnesium Alloys

Magnesium alloys are the lightest of the commonly used die-casting metals (approximately 33% lighter than aluminum), making them ideal for applications where weight reduction is critical. It also has a good strength-to-weight ratio, machinability, and damping capacity. Some common alloys:

- AZ91D: The most widely used magnesium die-casting alloy. It offers a good balance of strength, corrosion resistance, and castability. (AZ91D Alloy Datasheet)

- AM60B: Offers higher ductility and impact resistance than AZ91D.

Copper Alloys

Copper alloys, such as brass or bronze, are used in die casting when high strength, wear resistance, and corrosion resistance are required:

- Properties: High Strength, good wear resistance, and corrosion resistance.

- Typical Applications: Plumbing fixtures, electrical connectors, and marine hardware.

| Metal | Melting Point (°C) | Strength | Corrosion Resistance | Cost |

| Aluminum | ~600-660 | High | Excellent | Moderate |

| Zinc | ~380-400 | Moderate | Good | Low |

| Magnesium | ~600-650 | Moderate | Good | Moderate |

| Copper | ~900-1000 | Very High | Excellent | High |

Advantages and Disadvantages of Die Casting

While die-casting offers several benefits, such as fast production rates and excellent dimensional accuracy, it also has some limitations and drawbacks that you need to consider.

Advantages

- High-Dimensional Accuracy and Precision: Die casting produces parts with very tight tolerances and excellent dimensional repeatability. This minimizes the need for secondary machining operations.

- Excellent Surface Finish: Die-cast parts typically have a smooth, as-cast surface finish, often eliminating the need for extensive polishing or finishing.

- High Production Rates: The die-casting process is highly automated and capable of producing parts at very high speeds, making it ideal for large-volume production.

- Cost-Effective for Large Volumes: While the initial tooling cost (the die) is high, the per-part cost decreases significantly as production volume increases.

- Complex Shapes and Thin Walls: Die casting allows for the creation of intricate shapes and parts with thin walls, which can be difficult or impossible to achieve with other manufacturing processes.

- Long Die Life: Steel dies are durable and can withstand hundreds of thousands, or even millions, of casting cycles.

- Good Mechanical Properties: Die casting can create parts with good strength.

Disadvantages

- High Initial Tooling Cost: The cost of designing and manufacturing a steel die can be substantial, making die casting uneconomical for small production runs.

- Limited to High-Volume Production: The high tooling cost necessitates high-volume production to amortize the initial investment.

- Porosity: Some porosity (tiny air pockets or voids) can occur in die-cast parts, particularly in thicker sections. This can affect the part’s strength and pressure tightness.

- Limited to Certain Metals: Die casting mainly works with non-ferrous metals that have relatively low melting points. While some ferrous metals can be die-cast, it’s less common and more challenging.

- Size Limitations: There are practical limits to the size of parts that can be die-cast, depending on the size of the die-casting machine.

Applications of Die Casting in Modern Industries

Die casting serves a wide range of industries due to its versatility and efficiency. Here are some of the most common applications:

Automotive

Die casting plays an important role in the automotive industry by enabling the production of lightweight yet durable parts that meet the high-performance demands of modern vehicles. Many essential components, such as engine blocks, transmission cases, heat exchangers, and powertrain parts, are crafted using this process. Utilizing aluminum, zinc, and magnesium alloys helps reduce the overall weight of vehicles, leading to improved fuel efficiency, lower emissions, and enhanced handling. Moreover, it also supports the mass production of parts with precise tolerances, ensuring high-quality and reliable components.

Aerospace

In aerospace, die casting is crucial for manufacturing complex, high-performance parts used in both commercial and military applications. Key components like turbine blades, housings, brackets, and structural elements are produced through this method. Manufacturers commonly use lightweight, high-strength alloys such as titanium and aluminum, allowing the parts to withstand extreme temperatures and stresses while remaining as light as possible. The precision of die casting ensures that these components meet the stringent safety and performance standards required in the aerospace industry.

Electronics Industry

The electronics industry depends heavily on die casting to create housings and enclosures for devices like smartphones, laptops, power supplies, and other electronic equipment. Die-cast aluminum and zinc parts provide excellent shielding against electromagnetic interference (EMI) and ensure effective heat dissipation for electronic components. The precision and consistency of die casting enable manufacturers to produce intricate shapes with tight tolerances, which is essential for designing compact, high-performance devices.

Consumer Goods

Die casting also has a key role in the production of consumer goods, focusing on creating products that are not only functional but also attractive and durable. Items like kitchen appliances, furniture, tools, and sporting equipment often feature die-cast metal components. The process’s ability to achieve intricate designs with smooth finishes makes it an ideal choice for manufacturing high-quality consumer products. Additionally, die casting supports cost-effective, high-volume production, making it a go-to method for creating everyday items.

Medical Devices

In the medical device industry, it is crucial to produce precision components such as surgical instruments, diagnostic equipment, and housings for medical devices. These components must adhere to strict standards for accuracy, durability, and biocompatibility. Die casting enables the production of complex shapes with high precision, which is critical for devices that must perform reliably in sensitive environments. Lightweight, corrosion-resistant alloys like aluminum and zinc are often used, ensuring the durability and long-term performance of medical devices.

Die Casting Design Considerations

Designing parts for die casting requires careful consideration of several factors to ensure successful production and optimal part performance. These design principles aim to minimize defects, improve castability, and reduce overall costs.

Draft Angles

Draft angles are slight tapers applied to the vertical walls of a die-cast part. They are essential for facilitating the ejection of the solidified part from the die. Without the draft, the part would be difficult or impossible to remove without damaging the part or the die. A minimum draft angle of 1-2 degrees per side is typically recommended, although smaller angles may be possible with careful die design and lubrication.

Wall Thickness

Maintaining uniform wall thickness throughout the die-cast part is crucial for several reasons:

- Uniform Cooling: Uniform wall thickness promotes even cooling of the molten metal, minimizing distortion and internal stresses.

- Reduced Porosity: Thick sections can trap air and gases, leading to porosity. Maintaining consistent wall thickness helps to mitigate this issue.

- Minimum Wall Thickness: The minimum achievable wall thickness depends on the metal being cast and the size of the part. Zinc alloys can typically be cast with thinner walls than aluminum alloys.

- Maximum Wall Thickness: Avoid excessively thick sections, as they can lead to longer cooling times, increased shrinkage, and potential porosity.

Fillets and Radii

Sharp corners should be avoided in die-cast parts. Instead, use fillets (rounded internal corners) and radii (rounded external corners).

- Stress Concentration: Sharp corners act as stress concentrators, which can weaken the part and lead to cracking.

- Improved Metal Flow: Fillets and radii promote smoother metal flow during injection, reducing turbulence and improving the overall quality of the casting.

- Easier Ejection: Rounded corners facilitate part ejection.

Ribs and Bosses

Ribs and bosses are features that can be incorporated into die-cast parts to add strength and provide mounting points:

- Ribs: Thin, wall-like features that add stiffness and strength to a part without significantly increasing its overall weight.

- Bosses: Cylindrical protrusions that provide mounting points for screws, fasteners, or other components.

Undercuts

Undercuts are features that prevent the direct ejection of a part from the die. They require special die features, such as slides or lifters, to allow the part to be removed.

- Increased Complexity and Cost: Undercuts significantly increase the complexity and cost of the die.

- Alternatives: Whenever possible, try to design parts without undercuts or explore alternative design solutions that eliminate the need for them.

Tolerances

Die casting is famous for its ability to produce parts with tight tolerances, but it’s important to understand the achievable limits.

- Typical Tolerances: Typical dimensional tolerances for die casting range from ±0.001 to ±0.005 inches per inch (or ±0.025 to ±0.127 mm per 25 mm), depending on the metal, part size, and feature complexity.

- Factors Affecting Tolerances: Die wear, thermal expansion and contraction of the die and the part, and variations in the casting process can all affect the final tolerances.

- Specify Realistic Tolerances: Specifying unnecessarily tight tolerances can significantly increase the cost of production. Only specify tight tolerances where they are necessary for the part’s function.

Die Casting vs Other Manufacturing Methods

Here’s how die casting compares to other common methods:

| Feature | Production Rate | Dimensional Accuracy | Material Selection | Cost |

| Die Casting | High | High | Limited | High initial, low per part |

| Investment Casting | Moderate | High | Wide | Moderate |

| Sand Casting | Low | Low | Wide | Low initial, moderate per part |

| Injection Molding | High | High | Primarily plastics | Moderate initial, low per part |

How to Choose the Right Die-Casting Partner?

Selecting the right partner is crucial for ensuring quality and cost-efficiency. Here’s what to look for:

- Experience and Expertise: Choose a partner with a proven track record in your industry and expertise in the materials and methods you require.

- Production Capacity: Ensure the partner can handle your production volume, whether it’s small-batch or mass production.

- Certifications: Look for ISO certifications or other industry-specific quality standards.

- Customer References: Request case studies or testimonials to gauge the partner’s reliability and performance.

- Technology and Equipment: Ensure the partner uses modern technology for precision and efficiency.

As a leading company in die casting services, ABC Vietnam can make all the difference in product quality, cost efficiency, and timely delivery. With years of expertise, cutting-edge technology, and a commitment to precision, we provide high-quality die casting solutions tailored to your specific needs. Our skilled team ensures exceptional craftsmanship, whether for automotive, electronics, or industrial applications. By partnering with us, you gain access to a trusted manufacturer that prioritizes durability, efficiency, and competitive pricing. Contact us today for a quote!

Conclusion

Die casting is a powerful manufacturing process that offers a unique combination of speed, precision, and design flexibility. Its ability to produce high-quality, complex parts at high volumes makes it an essential technology across diverse industries. By understanding the intricacies of die casting and partnering with experienced professionals, businesses can leverage this versatile process to create innovative and market-leading products.