Aluminum is a popular material in sheet metal bending due to its lightweight, corrosion resistance, and aesthetic appeal. However, bending aluminum requires a strategic understanding of its properties and suitable techniques. The right method depends on the alloy, thickness, shape, and use case. Done wrong, and you’ll end up with cracks, springback, or even structural failure. In this guide, we’ll walk you through everything you need to know about aluminum bending – from material properties and bending methods to tools, safety, and expert tips.

What is Aluminum Bending?

Aluminum bending is the process of shaping aluminum sheets, rods, or extrusions using mechanical force, often with CNC machines and sometimes with heat assistance or annealing. It’s a key step in custom aluminum fabrication, widely used in the automotive, aerospace, and construction industries. Techniques like air bending, bottom bending, and coining are chosen based on the aluminum grade (such as 6061, 5052) and factors like springback or minimum bend radius. Proper die selection ensures precision and structural integrity. Finished parts may be anodized or powder-coated for durability and aesthetics.

What are the Key Properties of Aluminum That Affect Bending?

To effectively bend aluminum, it’s critical to understand the physical and metallurgical properties that dictate its behavior under stress. Aluminum’s response to forming forces depends not only on its base metal characteristics but also on specific modifications such as alloying, tempering, and processing history. The sections below provide an in-depth look at how these properties affect bend quality, radius control, and risk of cracking or springback.

Temper Condition

Temper refers to the metallurgical treatment history of aluminum, whether it’s been annealed, strain-hardened, solution-heat-treated, or aged. Tempers significantly influence bendability and are denoted by designations like -O, -H32, or -T6.

- O (annealed): Fully soft and the most ductile, this temper allows for the tightest bend radii without cracking. It’s ideal for manual bending or when small radius requirements are critical.

- H-temper (strain-hardened): These semi-hard tempers improve strength but reduce formability. For example, H32 indicates strain-hardened and partially annealed material, offering a balance of strength and workability.

- T-temper (heat-treated): Tempers like T6 are common in aerospace and structural applications due to their high strength. However, bending T6 aluminum often necessitates localized annealing or heating to prevent cracking due to reduced ductility.

Choosing the right temper is as important as selecting the alloy. Even the best alloy for bending can become problematic if it’s in a hardened state not suited to deformation.

Mechanical Properties

Two mechanical properties dominate when evaluating aluminum’s bendability: yield strength and elongation.

- Yield Strength: This measures the stress required to cause permanent deformation. Lower yield strength allows aluminum to bend more easily, but too low may compromise structural integrity. High yield strength, typical of T-tempers or 7xxx-series alloys, often leads to springback and fracture risks unless properly managed.

- Elongation (%): Indicates how much the material can stretch before breaking. Alloys with elongation greater than 10% are generally considered bend-friendly. For example, 5052-H32 has elongation values ranging from 10–18%, making it highly reliable in forming applications.

Understanding these mechanical metrics allows fabricators to fine-tune die selection, bend radius, and pressure control to optimize results and minimize failure.

Alloy Composition

Aluminum is commercially available in a variety of alloy series, each tailored for different performance criteria. The most common alloys used in bending are from the 1xxx, 5xxx, and 6xxx series.

- 1xxx Series (such as 1100): Nearly pure aluminum, this series offers excellent formability due to its low strength and high ductility. It’s ideal for aesthetic and electrical applications where corrosion resistance and malleability are prioritized.

- 5xxx Series (such as 5052, 5083): These magnesium-alloyed grades strike a balance between strength and formability, making them highly suitable for marine and automotive components. They exhibit good elongation properties and are less likely to crack under strain.

- 6xxx Series (such as 6061): These alloys include magnesium and silicon, offering higher strength but reduced ductility. Cold bending these without proper temper control or heat treatment can lead to surface cracking and internal fractures.

Each alloy behaves differently under stress due to variations in grain structure, strain hardening response, and residual stress from rolling or extrusion. For precision work, it’s crucial to match the alloy selection with the appropriate bending technique.

Springback

Springback is the elastic recovery that occurs after a bending force is released. It is more pronounced in aluminum than in steel due to its higher elastic modulus. This phenomenon is particularly challenging in high-yield-strength alloys like 6061-T6, where the final bend angle can deviate significantly from the intended shape if not compensated for. To counteract springback, you should:

- Increase overbend angles to account for expected rebound.

- Use bottoming or coining in press brake operations to reduce elasticity.

- Apply thermal softening in heat-treated alloys to reduce residual internal stresses.

Material Thickness

Intuitively, thicker aluminum requires more force to bend. However, thickness also significantly impacts the minimum bend radius achievable without cracking. As thickness increases, the minimum allowable bend radius also typically increases, especially for less ductile alloys. Bending a thick plate requires specialized heavy-duty equipment compared to bending thin sheet metal.

Bend Radius and Angle

The bend radius is the inside radius of the bend. A smaller bend radius is often desired for design aesthetics or functionality, but it puts more stress on the outer surface of the bend. Every aluminum alloy and temper has a minimum bend radius below which cracking is likely to occur. This minimum radius is usually specified as a multiple of the material thickness (such as 2T, meaning the minimum radius is twice the thickness). The bend angle is simply the desired angle of the bend.

Grain Direction (Anisotropy)

Aluminum sheet and plate material often exhibits anisotropic properties due to the rolling process, creating a “grain” direction. Bending aluminum across the grain (perpendicular to the rolling direction) is generally easier and less likely to cause cracking than bending parallel to the grain, especially with tighter radii. While not always possible, depending on the part layout, considering grain direction can improve bend quality.

Learn more: Common sheet metal bending defects and how to fix them

Tools and Equipment for Bending Aluminum

The quality of aluminum bending depends not only on material knowledge but also on selecting the appropriate tools based on project scale and precision requirements. Here, we divide the equipment into two main categories: tools suitable for DIY/home workshops and professional-grade machinery used in industrial settings.

DIY/Home Workshop Tools

For hobbyists, small business owners, or repair technicians, setting up a home workshop with basic aluminum bending capabilities is both achievable and cost-effective.

- Bench Vise and Manual Formers: A heavy-duty bench vise acts as the primary holding tool. By combining it with custom-made wooden, steel, or aluminum forms, you can achieve simple bends in thin sheets and rods. Angle blocks or homemade jigs further enhance consistency across multiple parts.

- Hand tools: Aluminum-specific pliers with smooth jaws prevent surface marring

- Mallets and Hammers: Rubber or rawhide mallets distribute force evenly without scratching the aluminum surface, ideal for fine-tuning bends.

- Heat sources: A heat gun (600-1100°F) provides controlled heating for thicker pieces

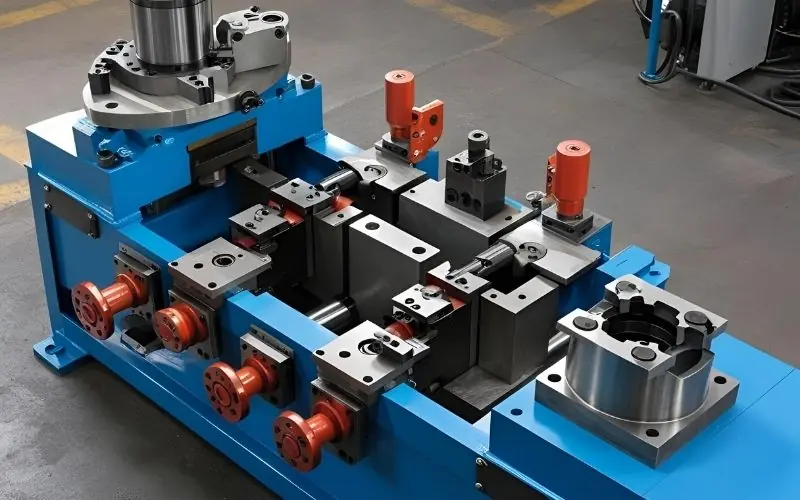

Professional/Industrial Equipment

Commercial operations typically utilize specialized equipment for precision and efficiency:

- Press brakes: Hydraulic or mechanical machines that create precise bends in sheet metal, offering tonnage capabilities from 10 to 1000+ tons

- Roll benders: Create smooth curves by passing aluminum between adjustable rollers

- Tube benders: Specialized for round, square, or rectangular aluminum tubing

- Automation and Integration: In high-output facilities, bending equipment is often integrated with robotic loaders/unloaders, real-time quality inspection systems, and manufacturing execution systems (MES) to optimize throughput and minimize human error.

5 Most Effective Methods for Bending Aluminum

A wide range of techniques exists for bending aluminum, each suited to different material forms, desired shapes, volumes, and precision requirements. Let’s explore the most common methods, ranging from simple manual techniques to sophisticated industrial processes.

Manual Bending (By Hand or with a Jig)

Manual bending is the most accessible method, commonly used for thin-gauge sheets or soft alloy rods. It’s best suited for simple bends without high tolerances. The material is clamped securely – typically in a bench vise – and bent by applying controlled pressure using a mallet or form tool. When precision matters, a custom jig or brake can standardize the angle and position. Always make a small test bend before committing to the final workpiece, especially with unfamiliar alloys. Marking and scoring the bend line with a utility knife or rotary tool can also help guide your bend and reduce stress concentrations.

Brake Press Bending

Brake presses, whether manual or hydraulic, provide precise, professional-grade bends. A V-shaped die and matching punch sandwich the aluminum sheet, exerting a consistent bending force. The result is clean, crisp angles with tight tolerances. Press brakes can be programmed (CNC-controlled) or adjusted manually. For each alloy and thickness, you’ll need to select the correct die opening to prevent cracking or under-bending. Protective films or non-marring dies may be used to preserve surface finishes, especially in decorative applications.

Heat-Assisted Bending

Some aluminum alloys, especially those with T-tempers, respond poorly to cold bending. In these cases, heating can increase ductility and reduce the chance of cracking. Using an oxy-acetylene torch, heat the bend area evenly until it darkens slightly – typically around 650°F (343°C). Overheating is a real risk, as aluminum doesn’t visibly glow before melting. A common trick is to use a soot mark from an acetylene-only flame: once it burns off, the metal is roughly at its bending temperature. After heating, proceed quickly with the bend, as the aluminum will cool rapidly.

Roll Bending

For larger radius curves or when working with tubing, roll bending is the preferred method. The material is gradually curved as it passes through three adjustable rollers. This method allows smooth, continuous bends with minimal deformation or surface marks. Roll bending requires careful setup – roller positioning, feed rate, and pressure must be adjusted for the alloy and wall thickness. It’s widely used in signage, piping, and curved architectural elements where aesthetics and consistency are paramount.

CNC and Rotary Draw Bending

Rotary draw bending is the most sophisticated method available, particularly for tight-radius applications and large-scale production. In this technique, the tube or profile is clamped into a die and drawn around a fixed radius. Computer Numerical Control (CNC) enhances repeatability and eliminates operator error. These machines can also manage compound bends and variable radii, making them ideal for aerospace, HVAC, and medical equipment manufacturing.

Conclusion

Mastering aluminum bending techniques opens up remarkable fabrication possibilities across countless applications. From understanding material science and mechanical stress to mastering tools and techniques, every detail plays a role in achieving the perfect bend. With the knowledge in this guide, you’ll be better equipped to make informed decisions, execute flawless bends, and elevate the quality of your work, whether in a factory or your garage.

FAQs

5052-H32 is one of the best options due to its excellent balance of strength and ductility, making it ideal for tight-radius bends. For projects with minimal strength needs but high formability, 1100-O is also a solid choice. Avoid 6061-T6 unless you can anneal or heat it beforehand.

Absolutely. Many alloys like 1100 and 5052 can be bent cold, especially in O-temper form. However, harder alloys such as 6061-T6 may require annealing or heat-assisted techniques to avoid fractures.

Avoid overly sharp bend radii, especially with heat-treated alloys. Choose ductile alloys and temper conditions suitable for cold work. If in doubt, heat the aluminum to reduce internal stresses and soften the structure before bending.